Photochemical method for synthesizing vitamine D3

A technology for photochemical synthesis and vitamins, which is applied in organic chemistry and other fields, can solve the problems of large-scale production difficulties, troublesome post-processing, and difficulty in realizing industrialization, and achieve the effects of increased yield, simple production process, and increased concentration of reactants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

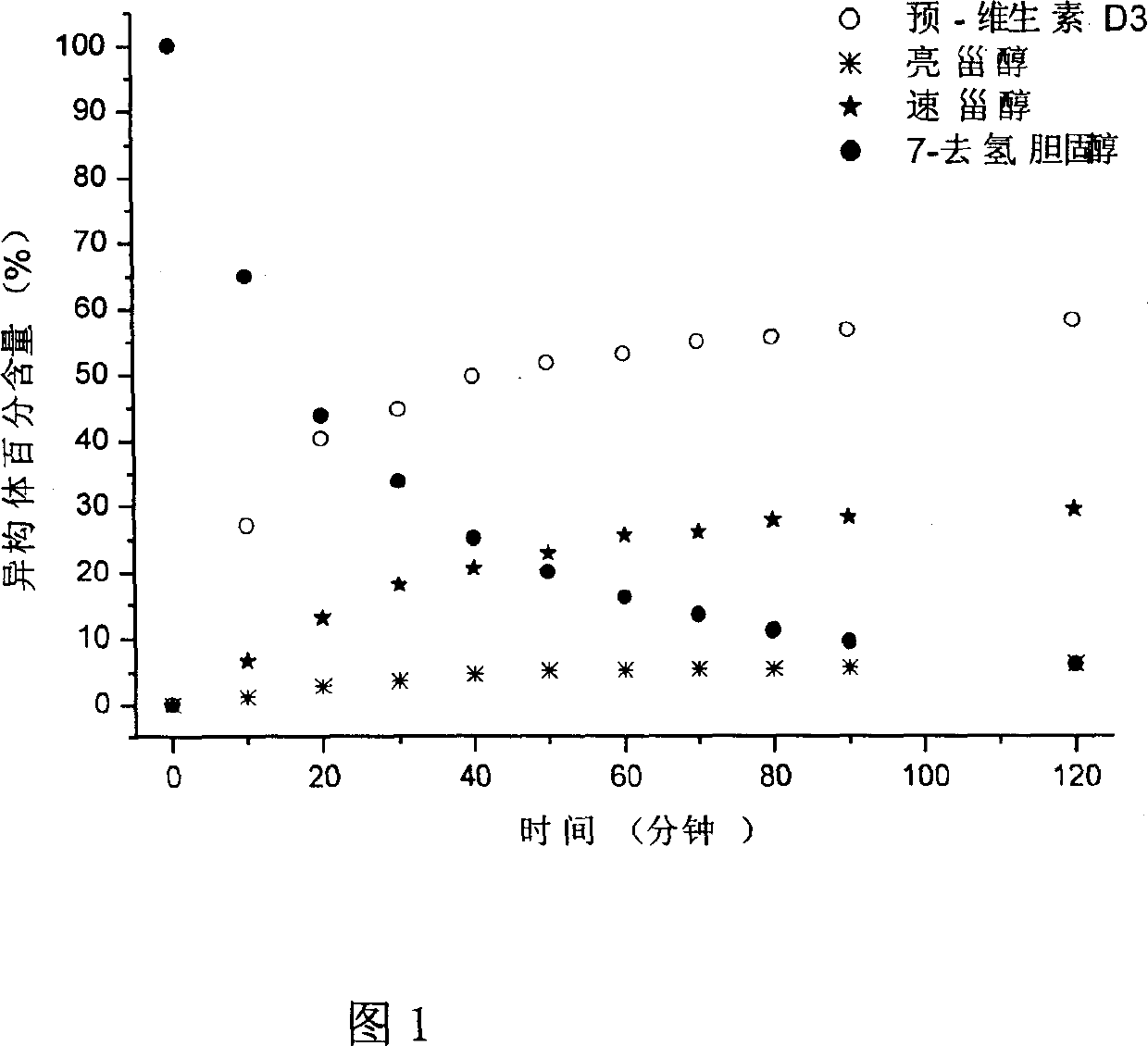

[0032] (1). Light reaction of 7-dehydrocholesterol

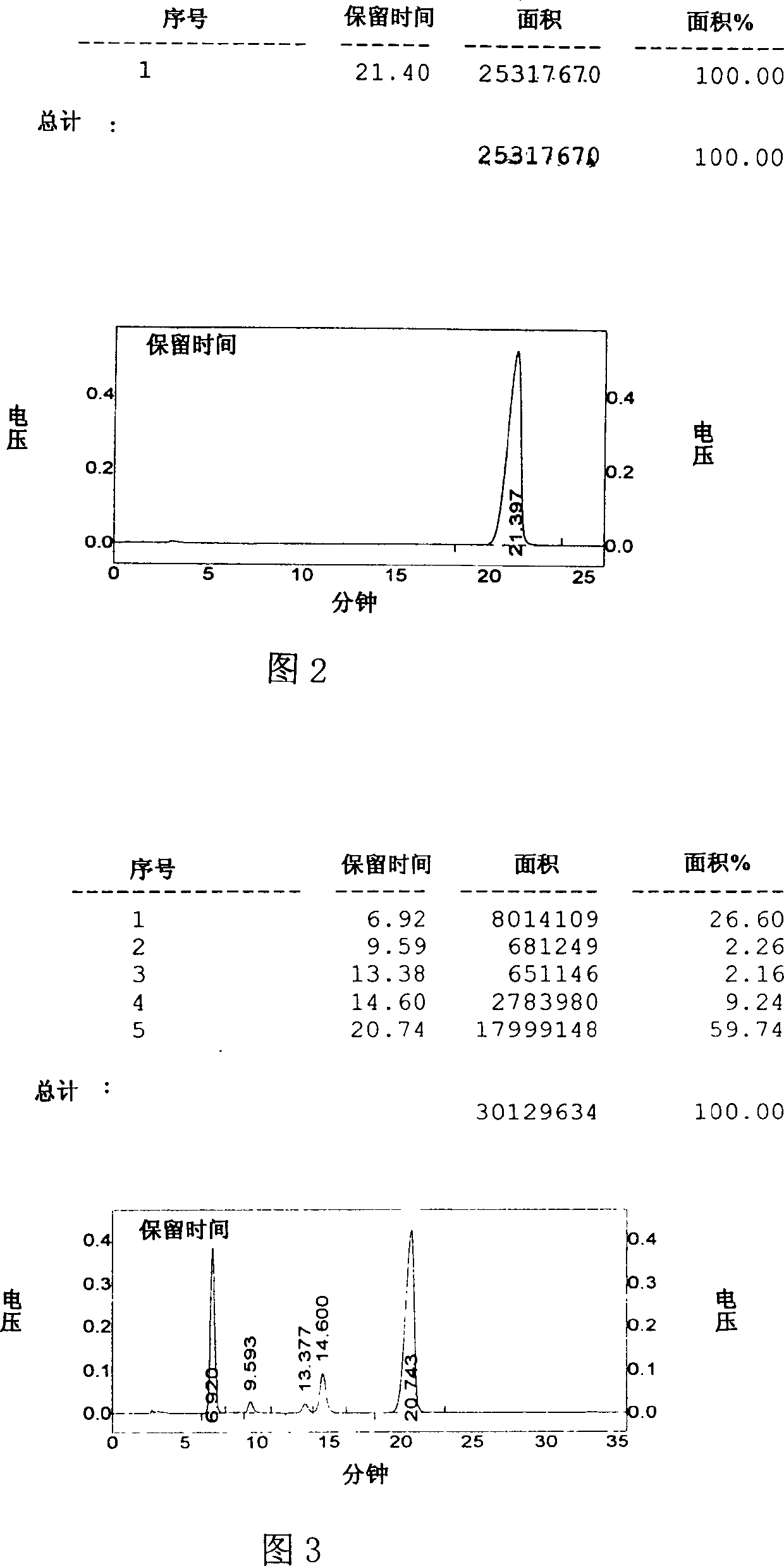

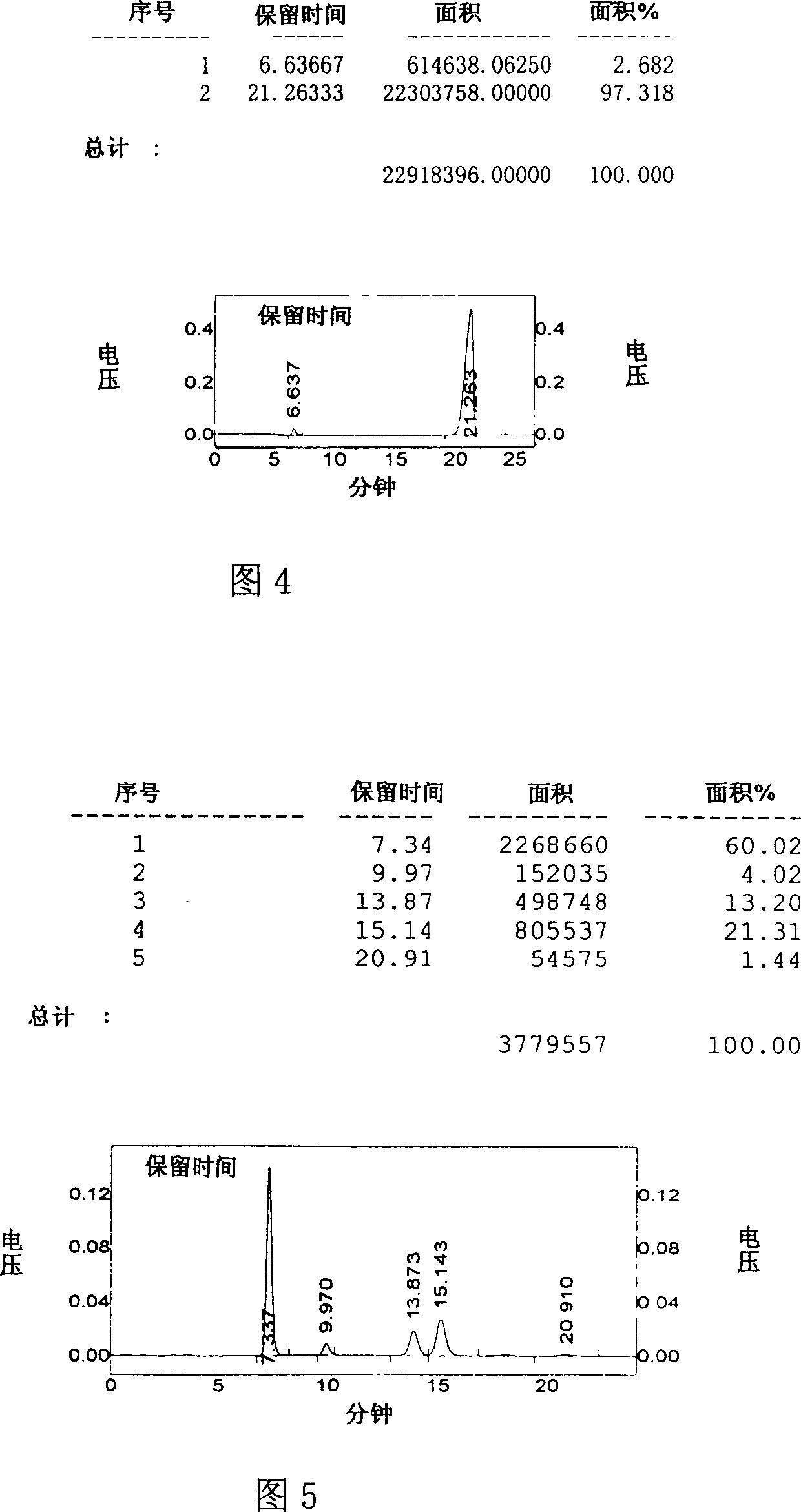

[0033] In a 500 ml round bottom flask, 16.5 g of 7-dehydrocholesterol was dissolved in 330 ml of petroleum ether (30-60°C)-ethanol (6:1, V / V) mixed solvent, and 10 mg of 2,6- Di-tert-butyl-p-methoxyphenol is uniformly mixed with magnetic stirring to prepare a photochemical reaction solution. The reaction solution was placed in a 450-watt high-pressure mercury lamp (Beijing Electric Light Source Research Institute GGZ1000-1) and an in-immersion photochemical reactor that was being ventilated with nitrogen. Adjust the nitrogen flow rate to make the bubbles uniform. Start the mercury lamp and time it. The reaction device is placed in a light-tight fume hood, and an electric fan is added to ensure that the temperature of the photochemical reaction solution does not exceed 28°C, so as to avoid premature formation of vitamin D during the photochemical reaction. 3 . The reaction was monitored by high pressure liquid chromatogra...

Embodiment 2

[0041] (1). Light reaction of 7-dehydrocholesterol

[0042] In a 500 ml round bottom flask, 16.5 g of 7-dehydrocholesterol was dissolved in 330 ml of pentane-methanol (6:1, V / V) mixed solvent, and 10 mg of 2,6-di-tert-butyl-p- Methoxyphenol, mixed evenly with a magnetic stirrer, and configured as a photochemical reaction solution. The reaction solution was placed into a 450-watt high-pressure mercury lamp (same as in Example 1) and in an in-immersion photochemical reactor that was being ventilated with nitrogen. Adjust the nitrogen flow rate to make the bubbles uniform. Start the mercury lamp and time it. The reaction device is placed in a light-tight fume hood, and an electric fan is added to ensure that the temperature of the photochemical reaction solution does not exceed 28°C, so as to avoid premature formation of vitamin D during the photochemical reaction. 3 . The reaction was monitored by high pressure liquid chromatography (HPLC) (conditions were the same as in Exa...

Embodiment 3

[0050] (1). Light reaction of 7-dehydrocholesterol

[0051] In a 500 ml round bottom flask, dissolve 16.5 g of 7-dehydrocholesterol in 330 ml of hexane-dioxane (6:1, V / V) mixed solvent, add 10 mg of 2,6-di-tert-butyl Base-p-methoxyphenol, mixed evenly with magnetic stirring, and configured as a photochemical reaction solution. The reaction solution was placed into a 450-watt high-pressure mercury lamp (same as in Example 1) and in an in-immersion photochemical reactor that was being ventilated with nitrogen. Adjust the nitrogen flow rate to make the bubbles uniform. Start the mercury lamp and time it. The reaction device is placed in a light-tight fume hood, and an electric fan is added to ensure that the temperature of the photochemical reaction solution does not exceed 28°C, so as to avoid premature formation of vitamin D during the photochemical reaction. 3 . The reaction was monitored by high pressure liquid chromatography (HPLC) (conditions were the same as in Example...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com