Cold rolling emulsion odor gas purifying device and method

A gas purification device and emulsion technology, applied in chemical instruments and methods, combined devices, separation methods, etc., to achieve the effects of increasing the concentration of reactants, improving reaction efficiency, and reducing pollutant load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

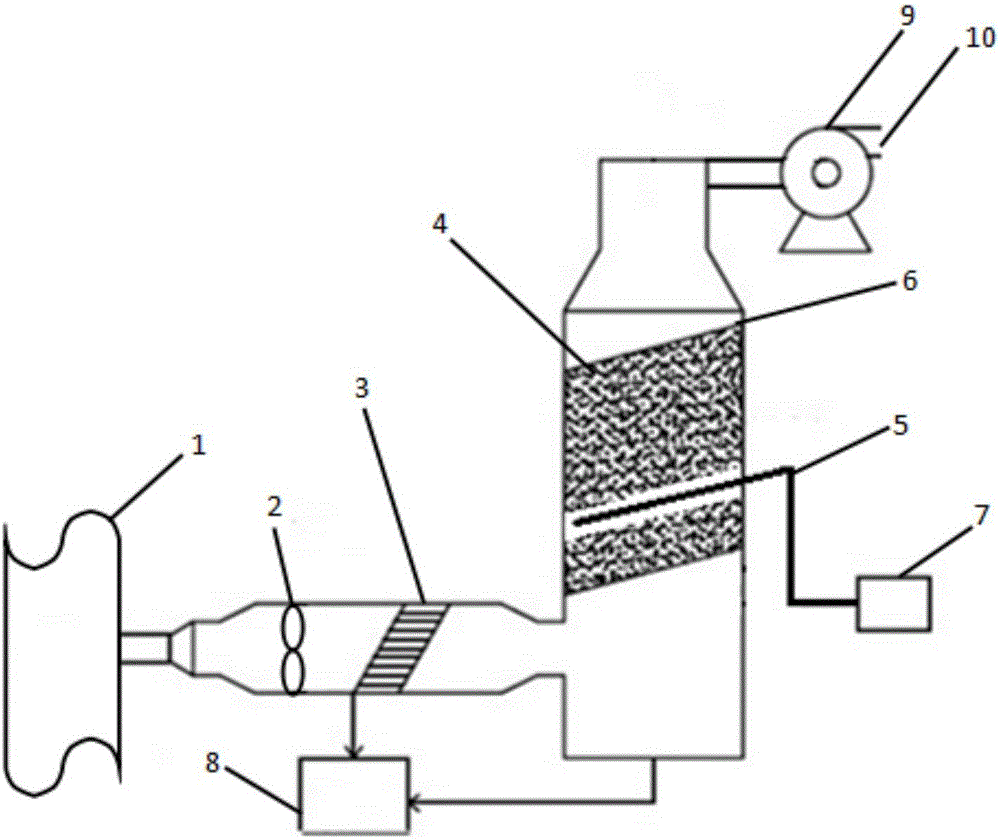

[0043] The exhaust gas produced by a cold rolling process of Baosteel Co., Ltd. is collected by the mist removal system of the rolling mill and then discharged. The oil mist content of the exhaust gas is ≤20mg / m 3 , the temperature is 20-40°C, the humidity is 60-95%, and the odor concentration is 550-977 (dimensionless), which meets the existing national "Odor Pollutant Emission Standard (GB14554-93)", but under certain meteorological conditions, the emission There will still be a perceivable smell of emulsion (smell) in residential areas around the mouth.

[0044] The oil mist content of the emulsion exhaust gas is less than 1 μg / m after passing through the centrifugal demister device 2 and the filter mechanical demister device 3 3 , the catalytic packing material 4 is an adsorption material and a catalyst, wherein the adsorption material is an activated carbon-based adsorption material with a carbon tetrachloride adsorption capacity of 100 to 120%, and the catalyst is Fe 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com