Bearing channel automatic sorting system

An automatic sorting and bearing channel technology, applied in sorting and other directions, can solve the problems of large changes in sorting accuracy and efficiency, and achieve the effect of high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

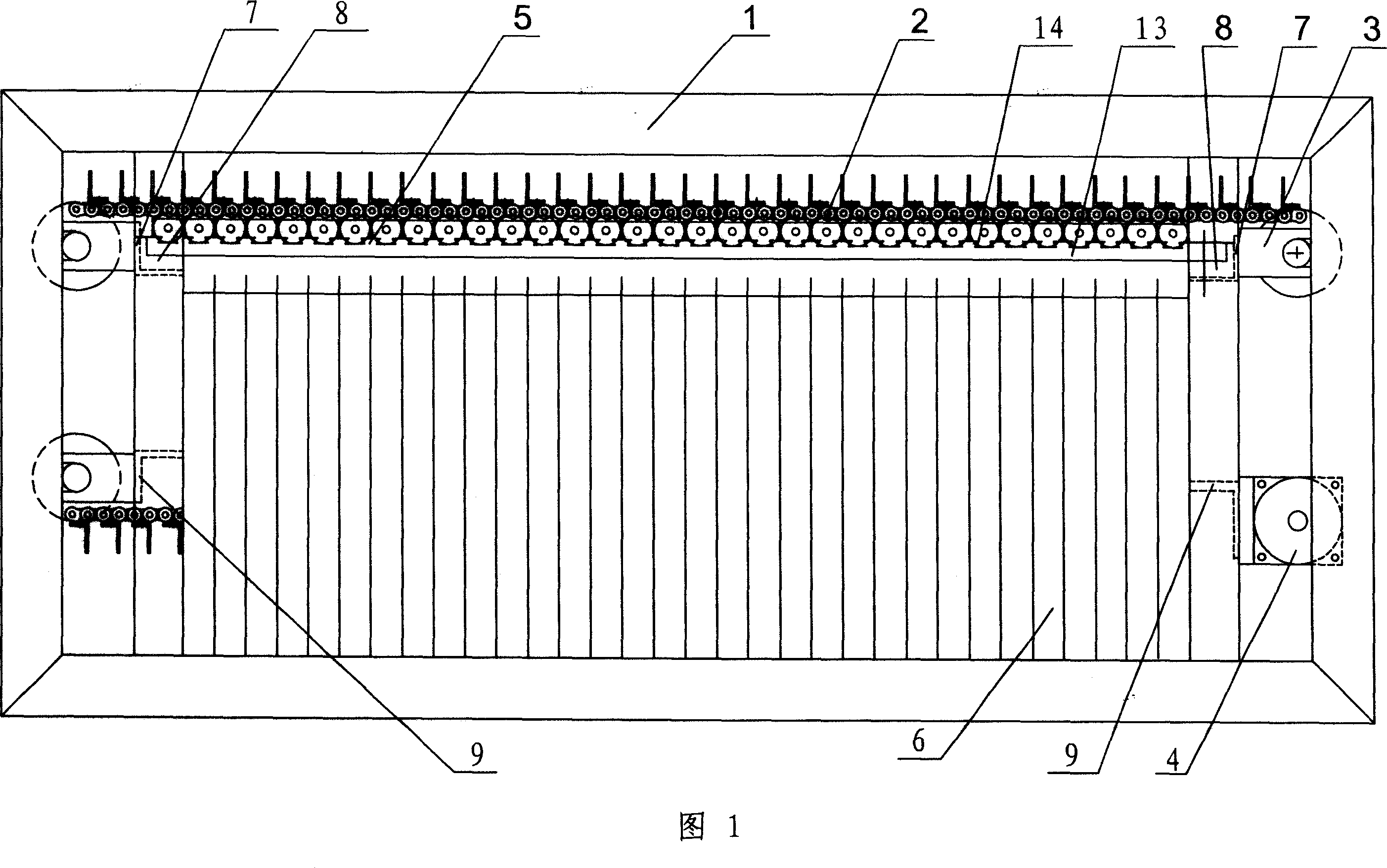

[0028] Bearing channel automatic sorting system, its composition includes: a frame 1 with an upper beam 7 and a lower beam 9, the frame 1 is respectively fixed with three supporting mechanisms 3 and a driving mechanism 4, and the three sprockets support 3 are respectively fixed on the outer sides of the upper beam 7 and the lower beam 9, the driving mechanism 4 is fixed on the outer side of the lower beam 9, the transmission mechanism 2 is installed on the driving mechanism 4, and a set of For the sorting mechanism 5, the frame 1 is provided with a storage bin 6, which is placed under the sorting mechanism 5 and aligned with each slider 22 up and down. Each slide acts as both a transfer chute and a storage hatch for workpieces. The running slideway and the storage hatch are combined into one, the cylinder is responsible for (or other means) to open or close the storage hatch, and the chain transmission mechanism is responsible for the operation of the workpiece, each time the ...

Embodiment 2

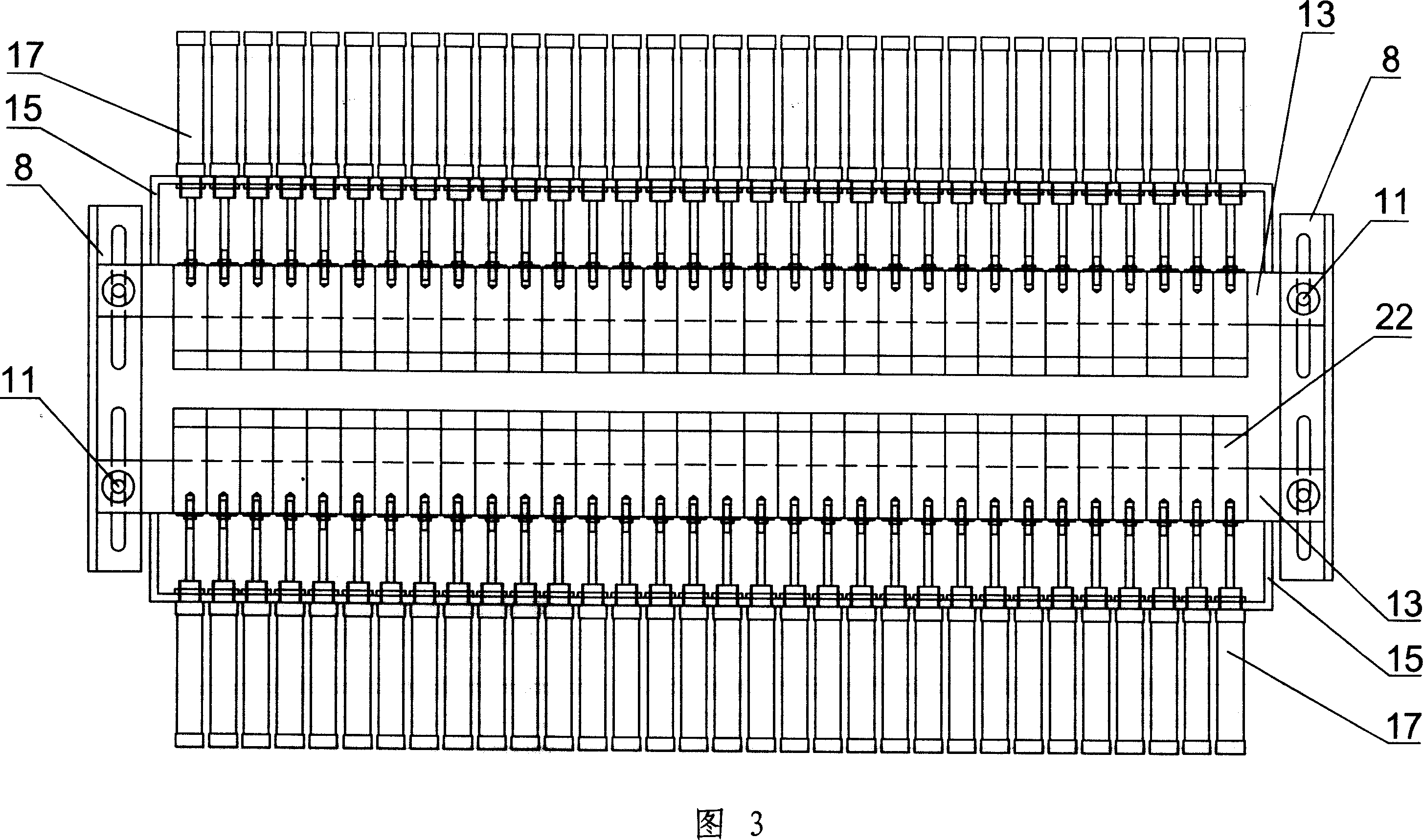

[0030] In the above-mentioned automatic sorting system for bearing channels, the sorting mechanism 5 includes a sorting chute supporting plate 8, and the described sorting chute supporting plate 8 is welded on the inner side of the upper beam 7, and the A slideway plate 13 is installed on the sorting slideway supporting plate 8, and the two are fixed with fasteners 11, 12. The slideway plate 13 is provided with a group of dovetail grooves 14, and the dovetail grooves 14 and The dovetail 19 on the slide block 22 cooperates, and a group of cylinder connecting plates 15 are welded on the described slideway plate 13, and the cylinder 17 is fixed on the described cylinder connecting plate 15 by nuts 18, and the piston rod of the described cylinder 17 Connected with the slider 22, the positioning plate 21 of each slider is respectively fixed between the slider and the piston rod through a nut 23, which acts as a positioning function to ensure that the front end of the slider is in a ...

Embodiment 3

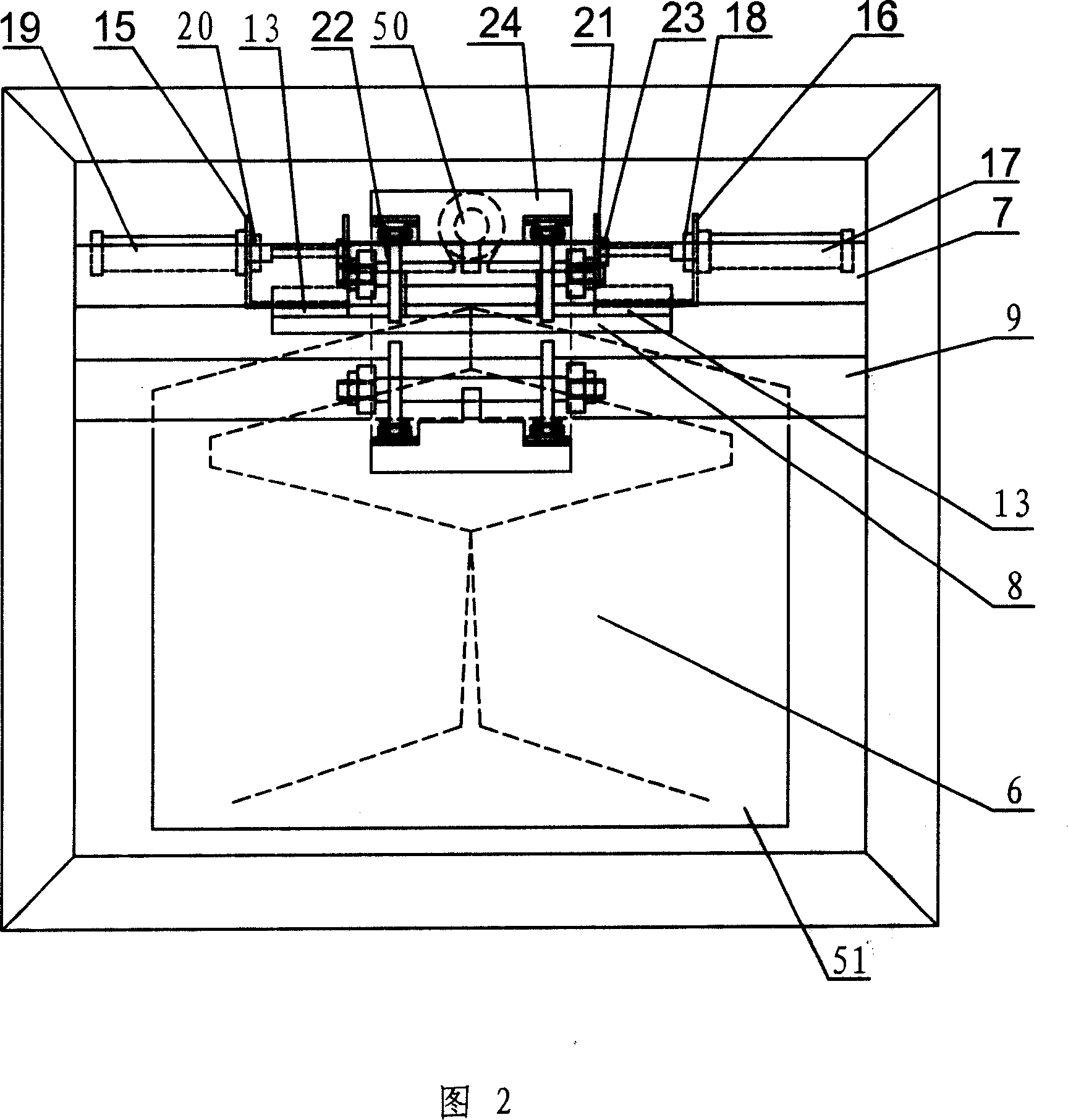

[0032] In the above automatic sorting system for bearing channels, the support mechanism 3 includes two copper bushings 25, and the two copper bushings 25 are respectively welded in the passive sprocket 29, and the shaft 26 is passed through the two copper bushings. 25, and the shaft 26 is fastened on the support 27 with a nut 28, and the support 27 is welded on the upper beam 7 of the frame 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com