Steel box beam erection method for self-anchored suspension bridge

A technology for self-anchored suspension bridges and steel box girders, applied in bridge construction, bridges, erection/assembly of bridges, etc., can solve the problems that are not suitable for the erection of self-anchored suspension bridges, the safety of river navigation is greatly affected, and the technical limitations of steel box girder erection and other problems to achieve the effect of overcoming local instability, increasing stiffness and reducing compressive stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

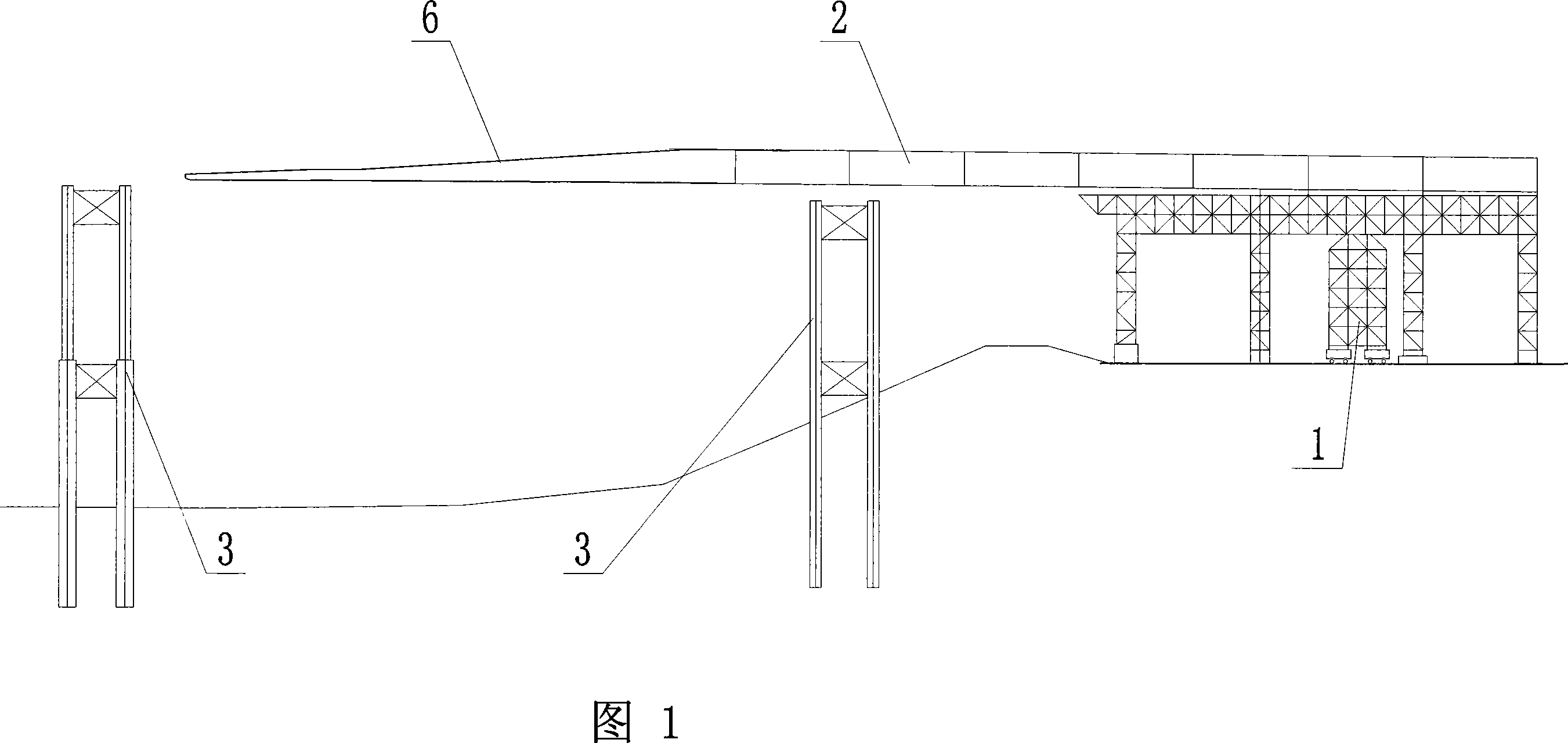

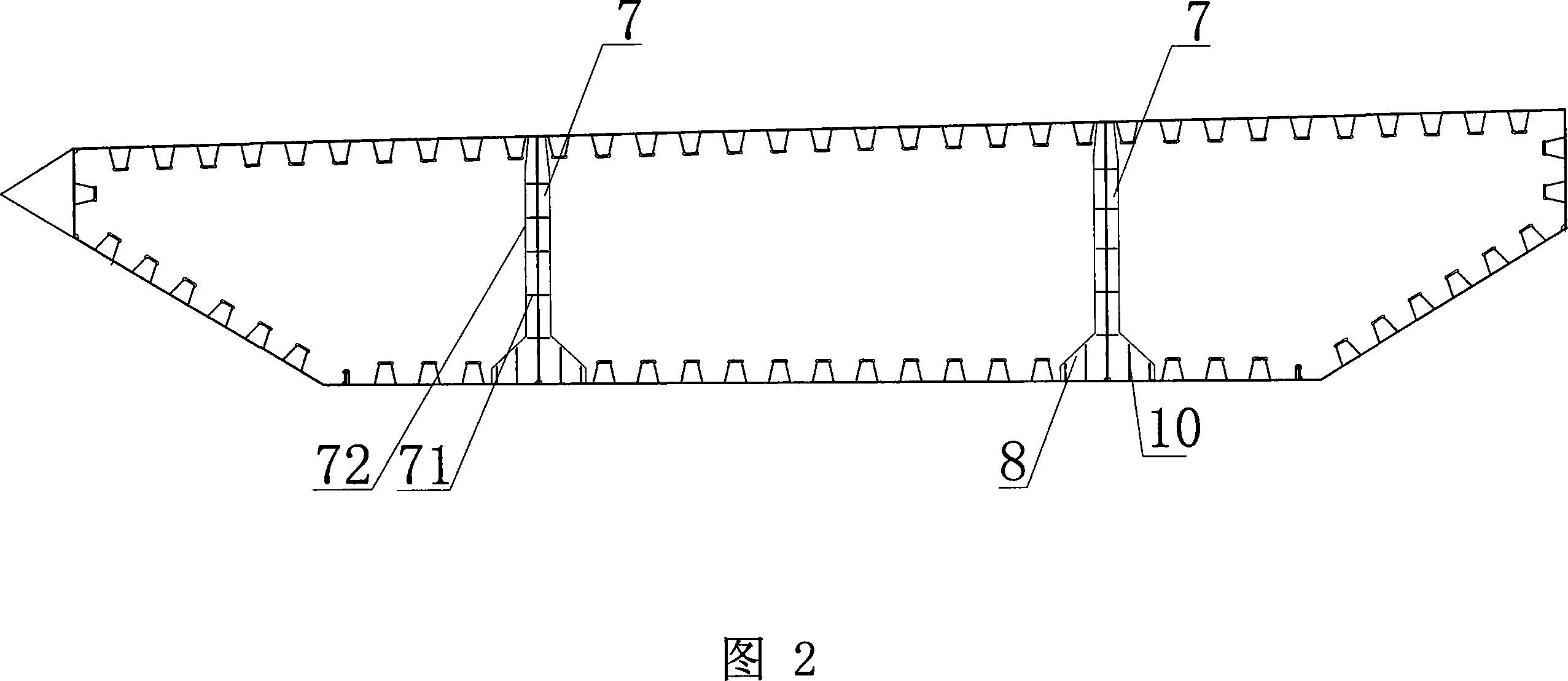

[0034] As shown in Figure 1, the steel box girder erecting method that the present invention is applied to self-anchored suspension bridge, its steps are:

[0035] (1), set steel box girder support 1 on the shore or non-navigation area, and carry out segmental pre-assembly of steel box girder 2 on steel box girder support 1;

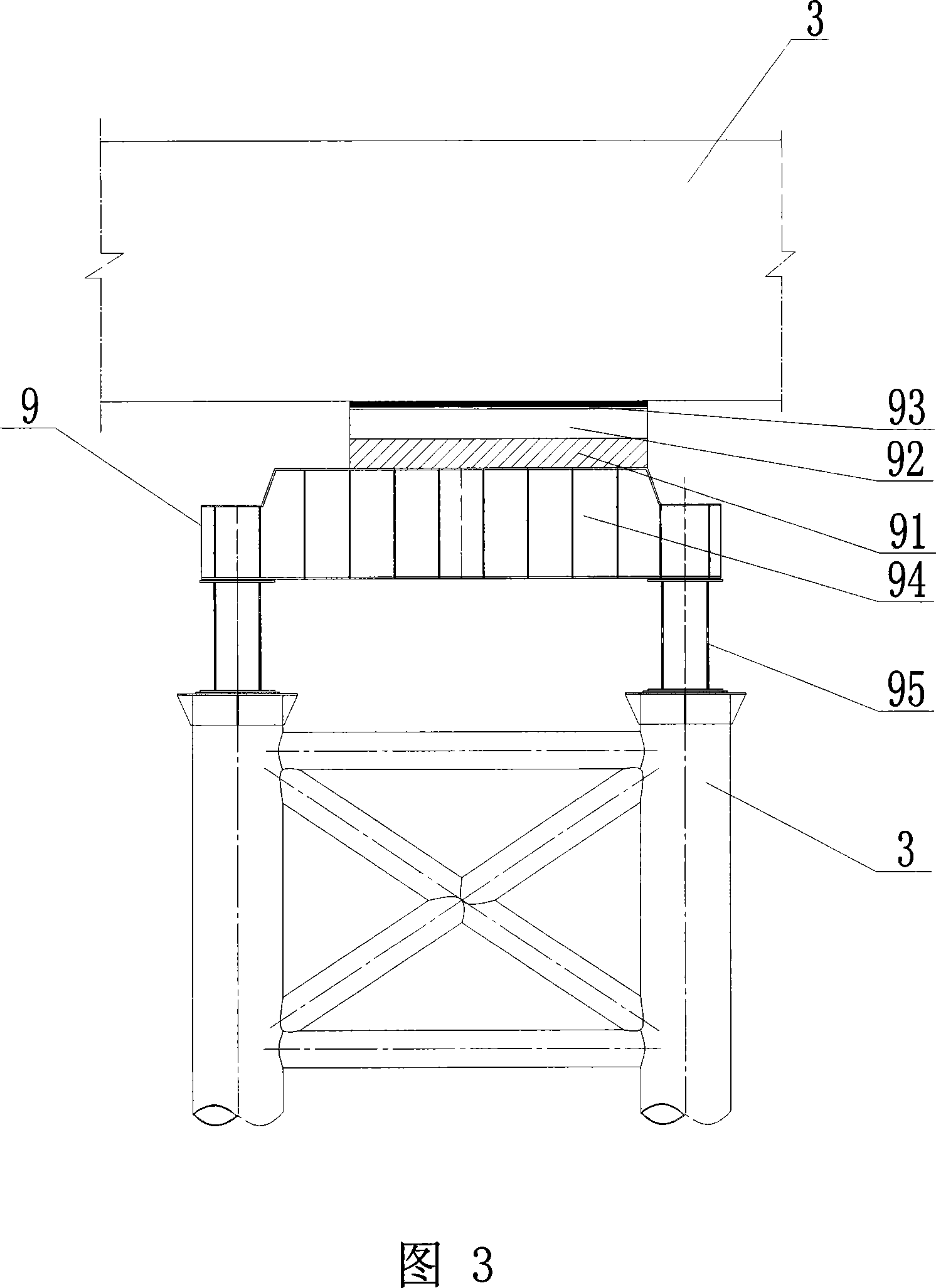

[0036] (2) Temporary piers 3 of steel box girders meeting the waterway level are set in the river channel crossed by the suspension bridge;

[0037] (3) Push the pre-assembled steel box girder 2 forward by pushing or dragging, so that the steel box girder 2 is moved from the steel box girder bracket 1 to the steel box girder temporary pier 3, and the steel box girder is used to temporarily Pier 3 support; then continue to pre-assemble the steel box girder 2 in sections, push or drag continuously, so that the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com