Wave web steel arch structure

A wavy web and wavy technology, applied in the field of new wavy web steel arch structures, can solve the problems of waste of leftover materials, low utilization rate of plates, local buckling, etc., and achieve convenient forming and processing processes and high buckling strength. , the effect of large out-of-plane stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A detailed description will be given below in conjunction with the accompanying drawings.

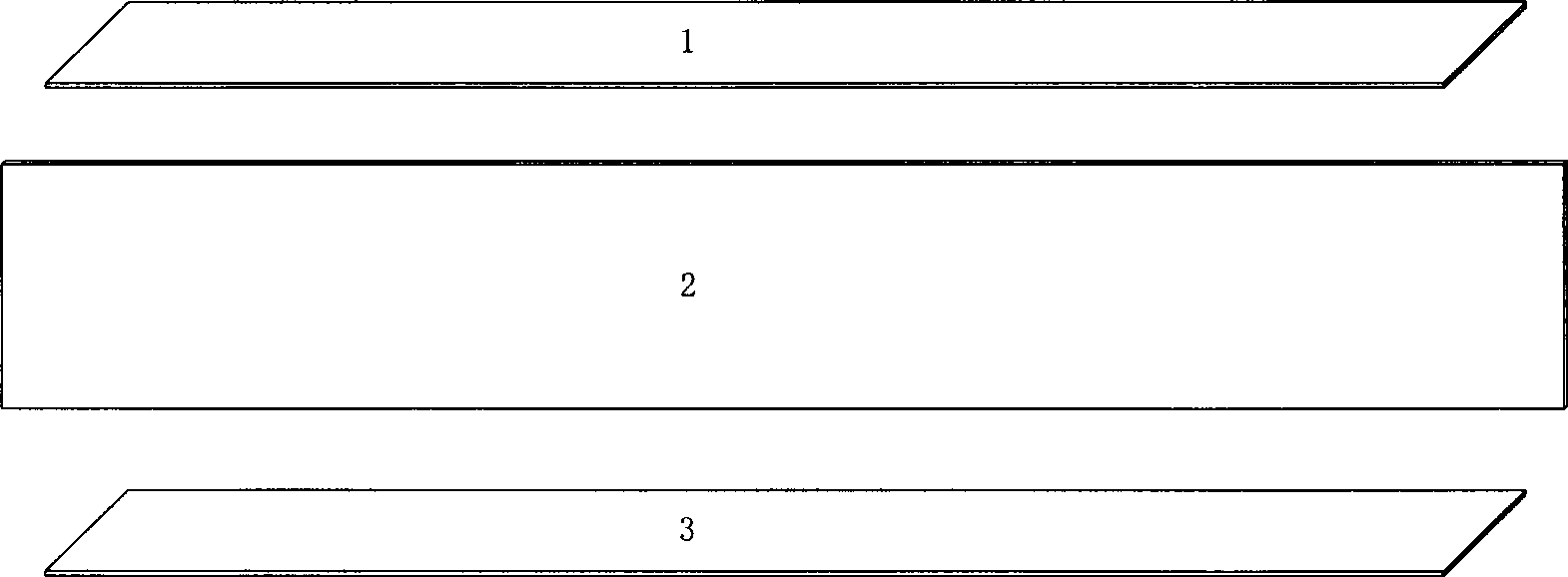

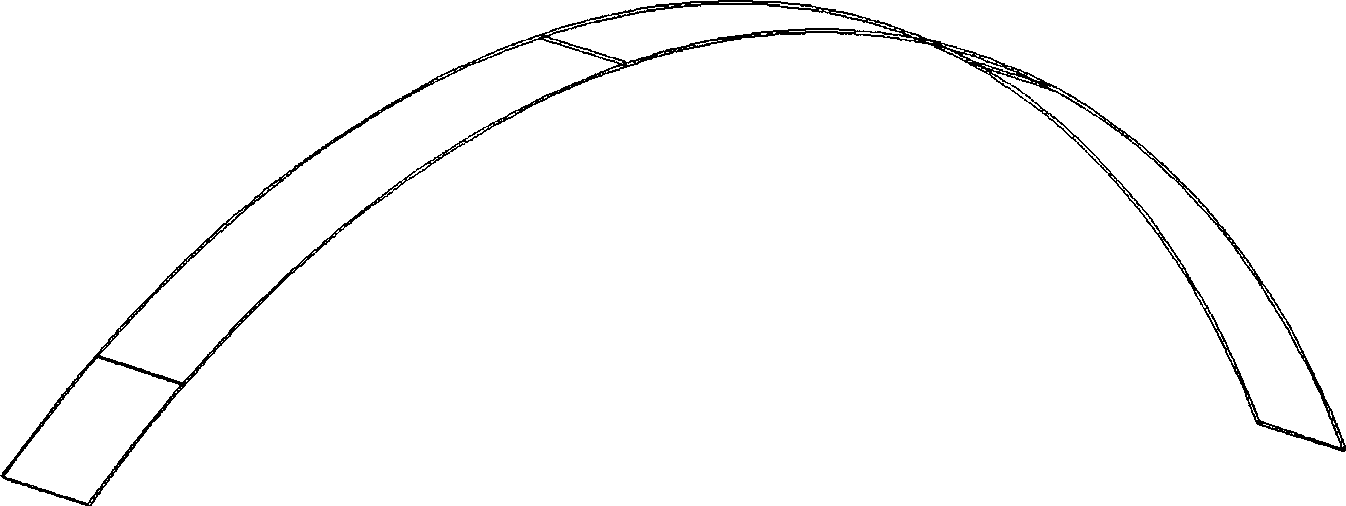

[0015] Such as Figure 1~5 Shown in the figure: 1-upper flange plate 2-wavy arc web 3-lower flange plate.

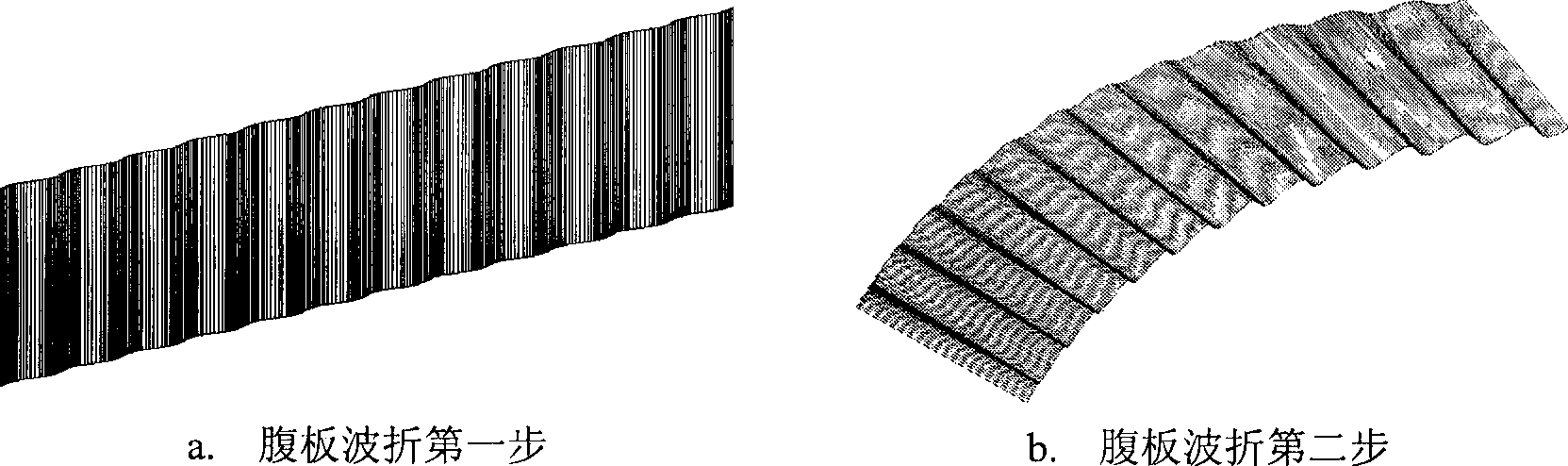

[0016] Such as figure 1 As shown, the blanking of the corrugated web steel arch member is very regular. Through cold bending equipment, the upper and lower flange plates can be cold bent into such figure 2 Arched as shown. The corrugation forming of the web is completed in two steps, such as image 3 As shown, in the first step, the web is folded into uniform waves, and in the second step, by adjusting the height of the upper and lower amplitudes of the web, the web can automatically form an arch, and by adjusting the height ratio of the upper and lower amplitudes of the web, different rise-span ratios can be formed The wavy curved web. The upper and lower flange plates are connected to the web by welding, and the actual processing can be completed by an automatic we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com