Variable-cross-section corrugated steel plate-concrete combined plate structure

A technology of corrugated steel plate and composite plate, which is applied in the direction of floors, building components, building structures, etc., can solve the problems of reducing the efficiency of longitudinal prestressing, reducing the efficiency of concrete, and the large amount of concrete used, so as to reduce weight, reduce difficulty, The effect of reducing the principal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

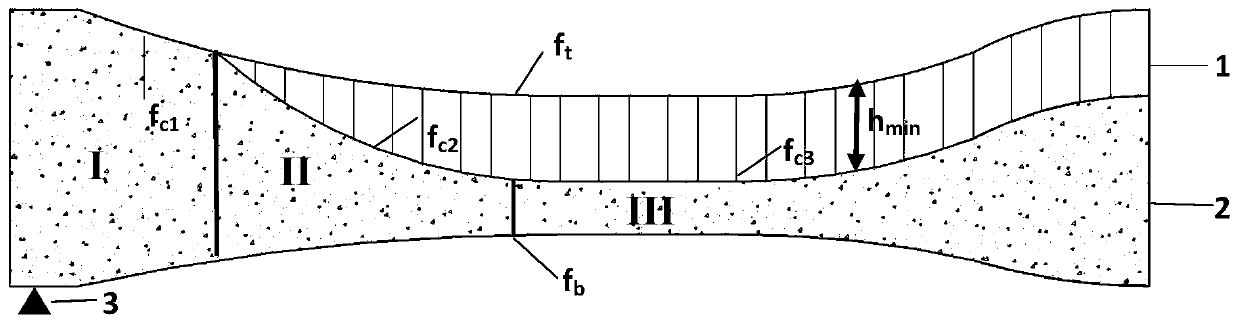

[0026] Embodiment 1: as image 3 Shown is a schematic diagram of the structure of a corrugated steel plate-concrete composite slab with equal cross-section. Among them, the top surface line shape of the corrugated steel plate 1 is f t , Corrugated steel bottom line type f b Both are linear; Lined concrete 2 bottom surface line and corrugated steel plate bottom surface line type f b Coincident; the first top linetype f of the full-section segment I c1 and corrugated steel top surface line type f t Coincident; second top linetype f of transition section II c2 Straight-line transition is adopted, and the thickness adopts equal-thickness transition; the third top surface line type f of the smallest section section III c3 Satisfy the top linetype f t The height of the third top surface minus the linear f c3 The height is less than the minimum height h min , here make the third top surface linetype f c3 and corrugated steel top surface line type f t Parallel, and linearly ...

Embodiment 2

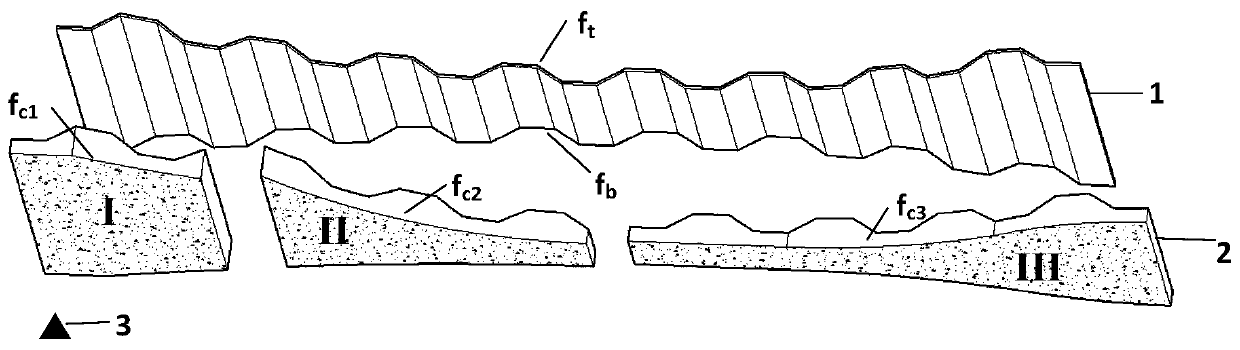

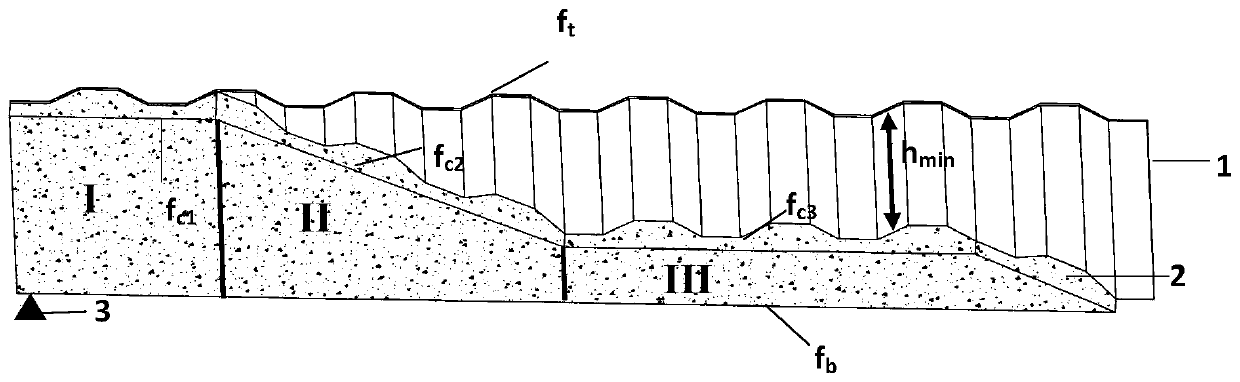

[0027] Embodiment 2: as Figure 4 As shown in , it is a schematic diagram of the structure of the corrugated steel plate-concrete composite plate with variable cross-section on the bottom surface. Among them, the top surface line shape of the corrugated steel plate 1 is f t It is straight line type, bottom line type of corrugated steel plate f b The second half is a convex curve; the bottom line of the lined concrete 2 and the bottom line of the corrugated steel plate f b Coincident; the first top linetype f of the full-section segment I c1 and corrugated steel top surface line type f t Coincident; second top linetype f of transition section II c2 Step transition is adopted, and the thickness adopts equal thickness transition; the third top surface line type f of the minimum section section III c3 Satisfies the condition top surface line type f t The height of the third top surface minus the linear f c3 The height is less than the minimum height h min , here make the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com