Hanging basket with self-locking wheel track type running gear and running method of hanging basket using said running gear

A walking device and wheel-rail type technology, which is applied in erecting/assembling bridges, buildings, bridge construction, etc., can solve problems such as complex structure, overturning of hanging baskets, and sudden increase of sliding friction, and achieve a simplified overall structure, easy installation, and good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

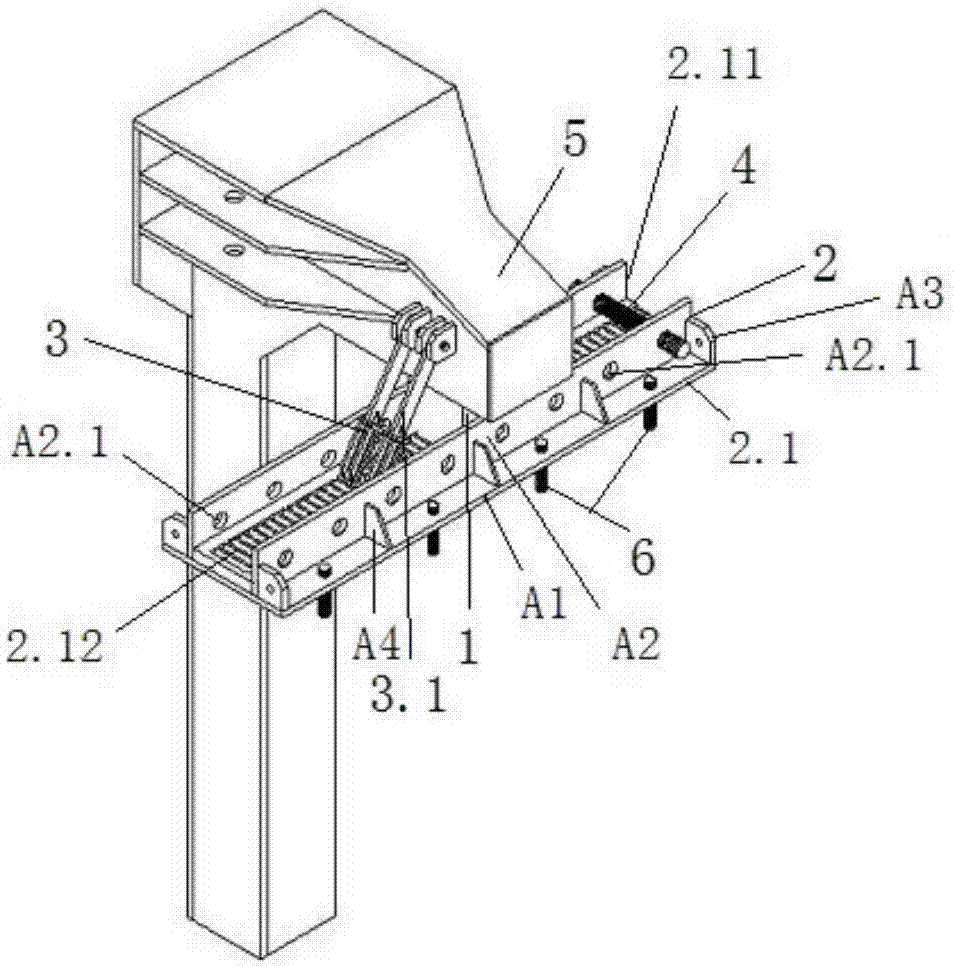

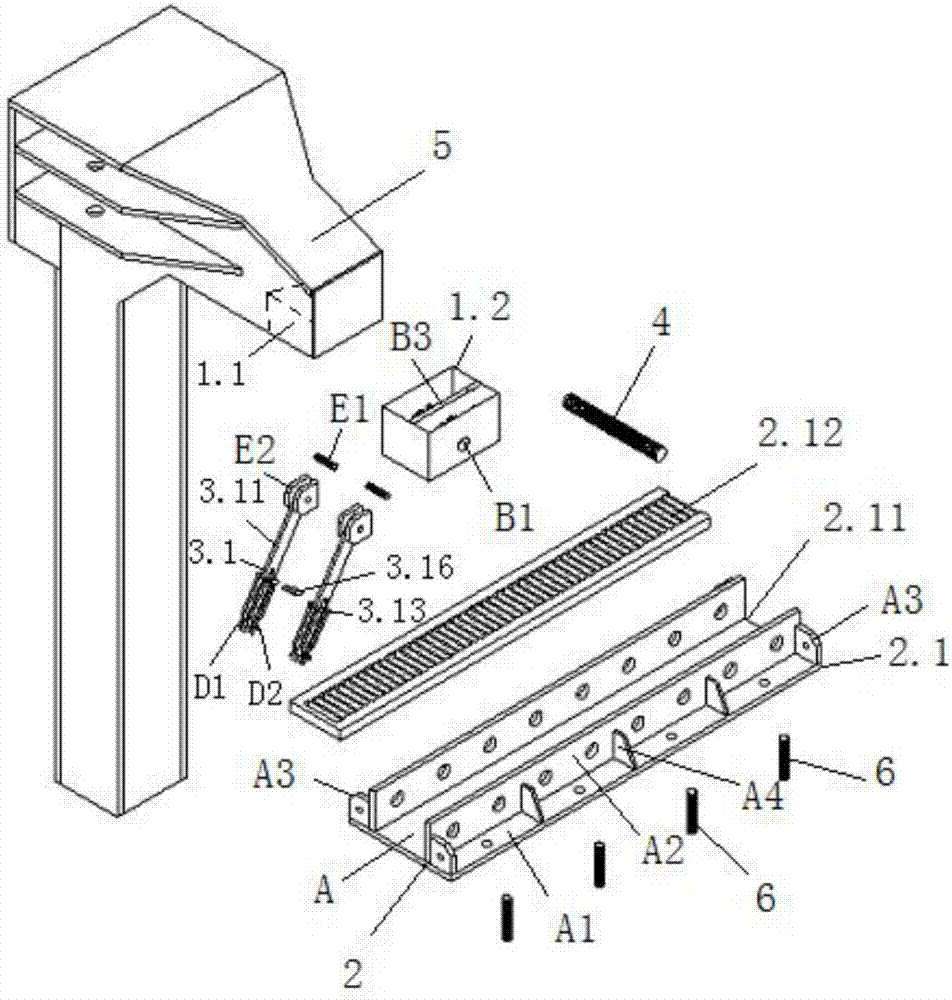

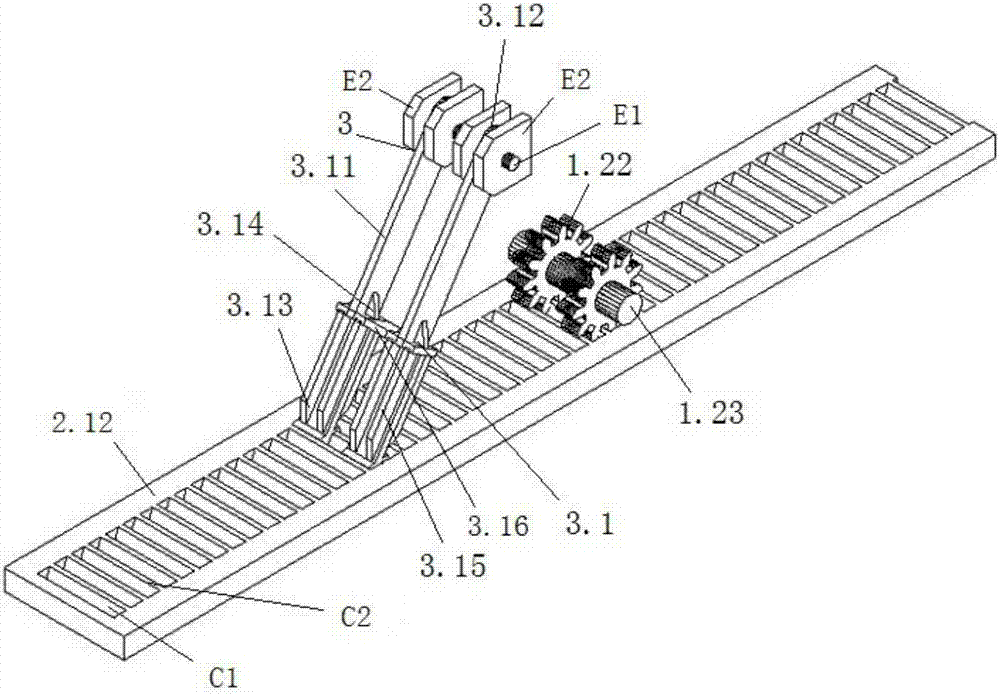

[0054] see Figure 1-Figure 4 , a hanging basket with self-locking wheel-rail type walking device, with the same number of hooks as the hanging basket and one-to-one corresponding walking parts, which can realize synchronous walking or independent walking of multiple hooks of the hanging basket to meet different needs. The walking parts include a walking structure 1, a track structure 2, a defense structure 3 and an anti-derailment part 4, and the specific structure is as follows:

[0055] The walking structure 1 includes a power source 1.1 welded on the hook 5 and a rolling boat 1.2 welded to the hook of the hanging basket and driving the rolling boat to walk. Here, the power source 1.1 adopts a motor, which is arranged inside the hook 5 . The rolling boat 1.2 includes a shell 1.21, a roller set 1.22 and a bearing 1.23. The shell 1.21 is a hexahedron structure with an open upper end and a cavity (each face of the hexahedron is connected by welding), and a spacer is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com