Assembled double steel plate combined shear wall structure with rib plates and construction method of structure

A combination of shear wall and shear wall technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of buckling deformation, shear wall strength reduction, concrete is not easy to compact, etc., to improve deformation capacity, improve wall Decent external stiffness, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]A specific embodiment of the present invention is described in detail below, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment;

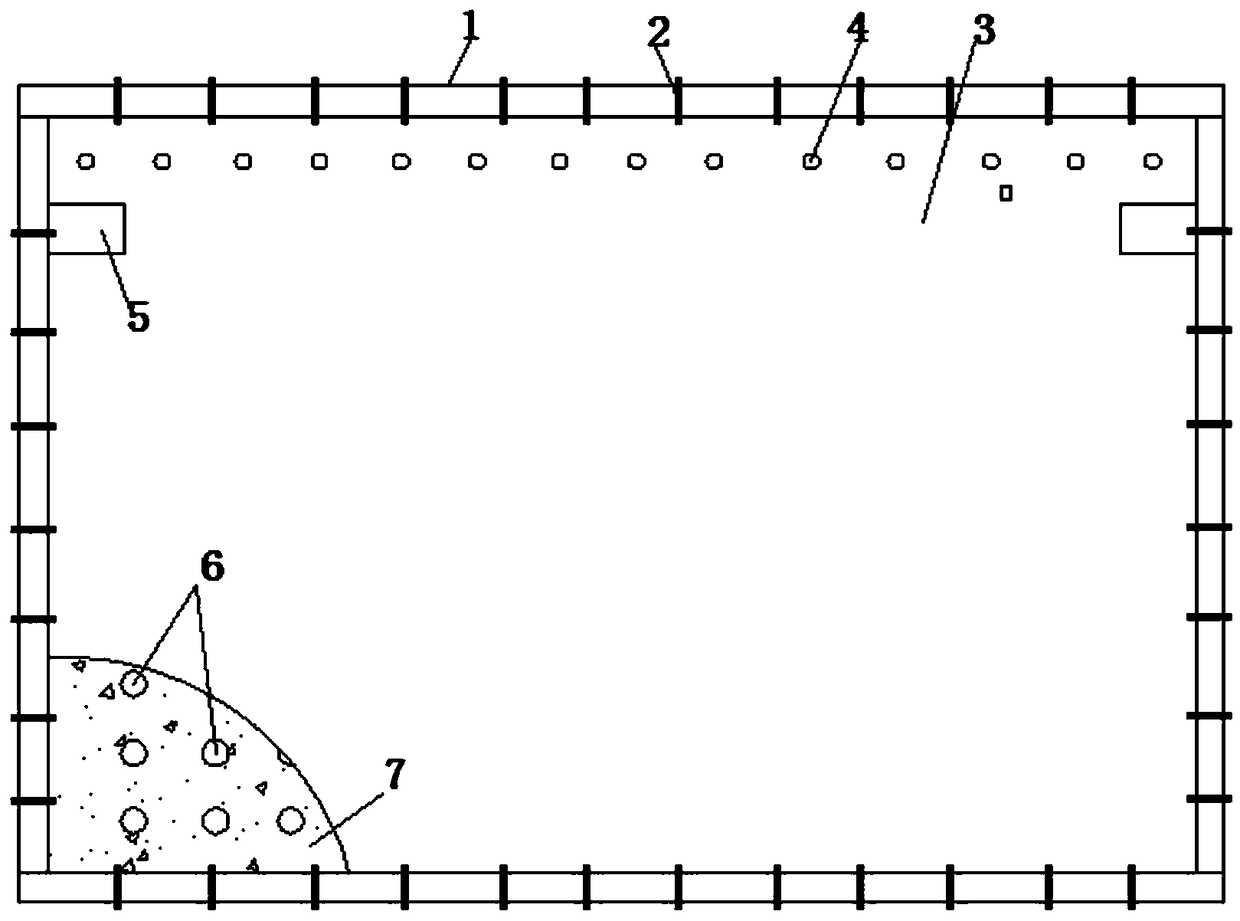

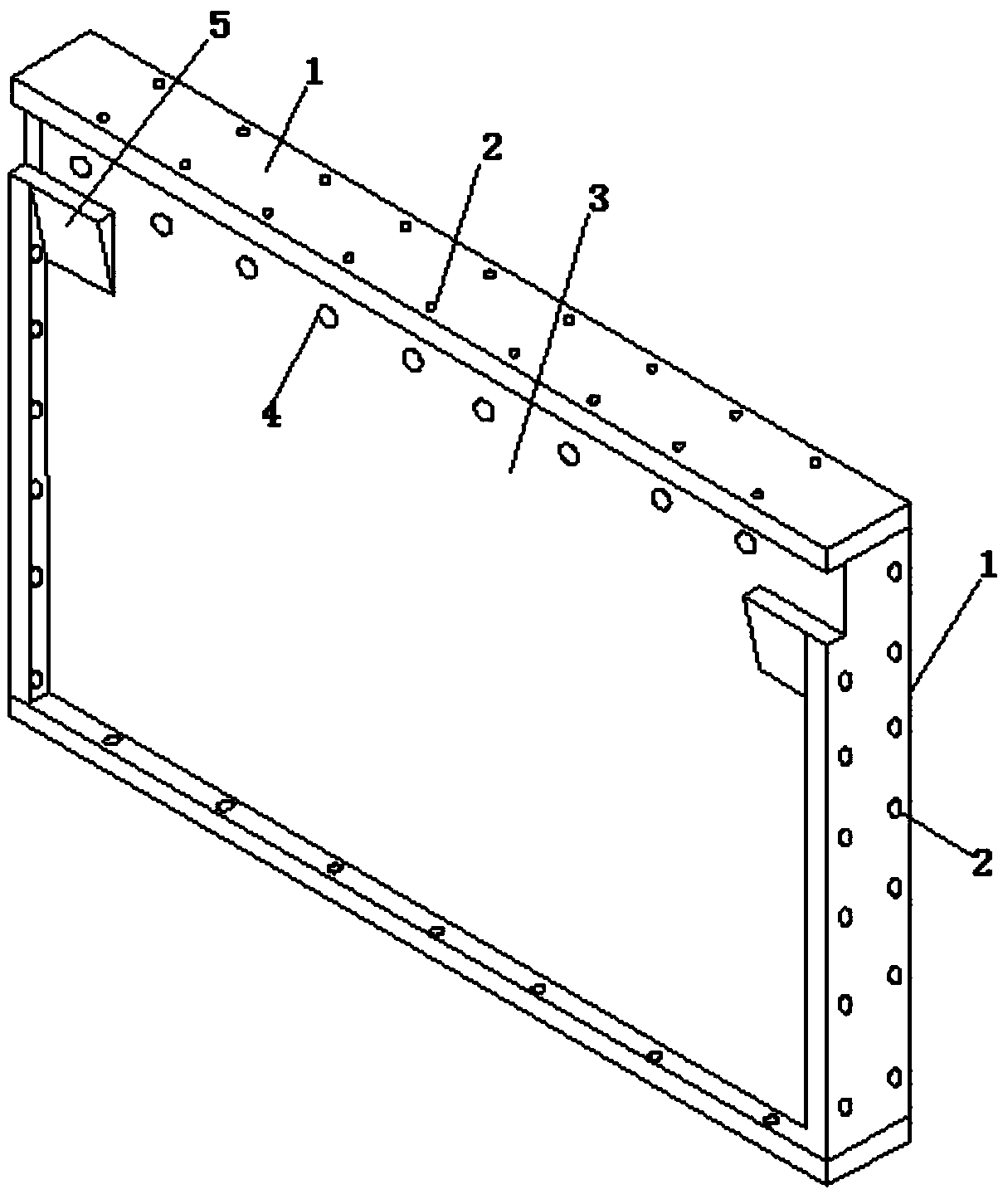

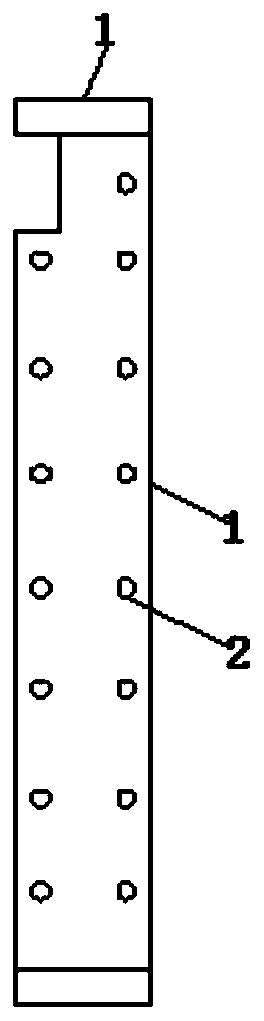

[0039] Such as Figure 1-13 Shown: a ribbed assembled double-steel plate combined shear wall structure; including the outer wall of the shear wall and the inner wall of the shear wall; the outer wall of the shear wall and the inner wall of the shear wall each include four ribs 1 and two steel wall panels 3; the four ribs 1 are arranged around, and the two steel wall panels 3 are arranged on both sides, forming a box-shaped shear wall shell by welding; the ribs 1 is evenly provided with high-strength bolt holes 2 or pull bolt holes a; the upper parts of the two steel wall panels 3 are neatly provided with pull bolt holes b4, and a grouting hole is opened in the upper part of one steel wall panel 3, In addition, an air vent is provided on both sides; the interior of the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com