Corrugated type replaceable energy dissipation device with controllable performance

An energy dissipation device, corrugated technology, applied in the direction of building types, protective buildings/shelters, building components, etc., can solve problems affecting the performance stability of steel plates, low cycle fatigue resistance, unfavorable rapid repair and replacement, and increase energy dissipation. weight and other issues, to avoid adverse effects, reduce the degradation of in-plane bearing capacity and stiffness, and reduce costs and time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

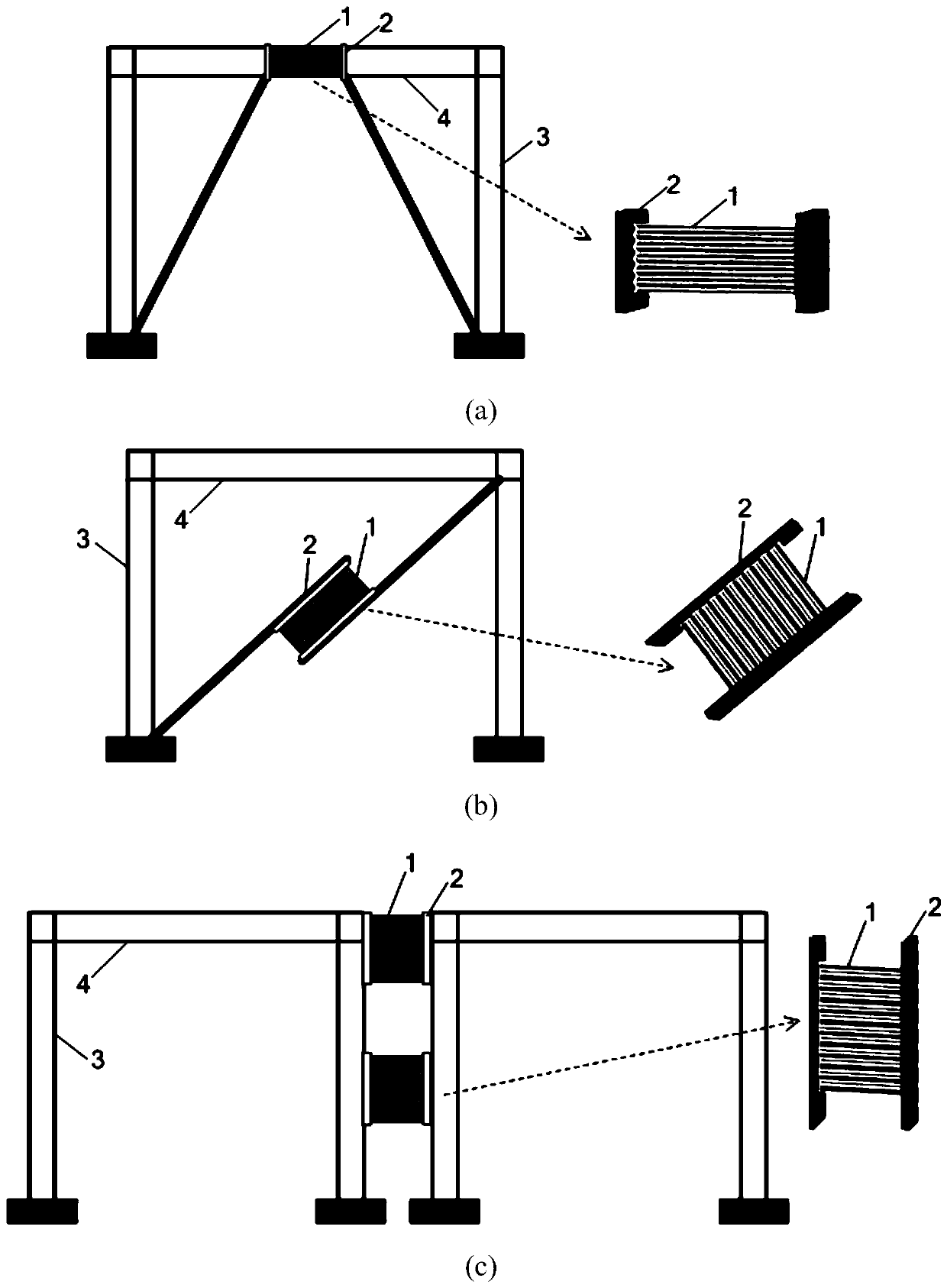

[0023] Embodiment 1: as figure 1 As shown, the present invention is a corrugated type replaceable energy dissipation device with controllable performance, which is mainly composed of corrugated steel plate 1 and connecting plate 2. Energy-dissipating beam sections, energy-dissipating supports of steel-supported frame systems, and between steel columns of steel-column steel frame systems, etc. The corrugated steel plate 1 is rolled in a factory, and the corrugated steel plate 1 and two connecting plates 2 are welded and connected. The corrugated steel plate 1 maintains elasticity under frequent earthquakes, and yields and consumes energy under fortification earthquakes and rare earthquakes.

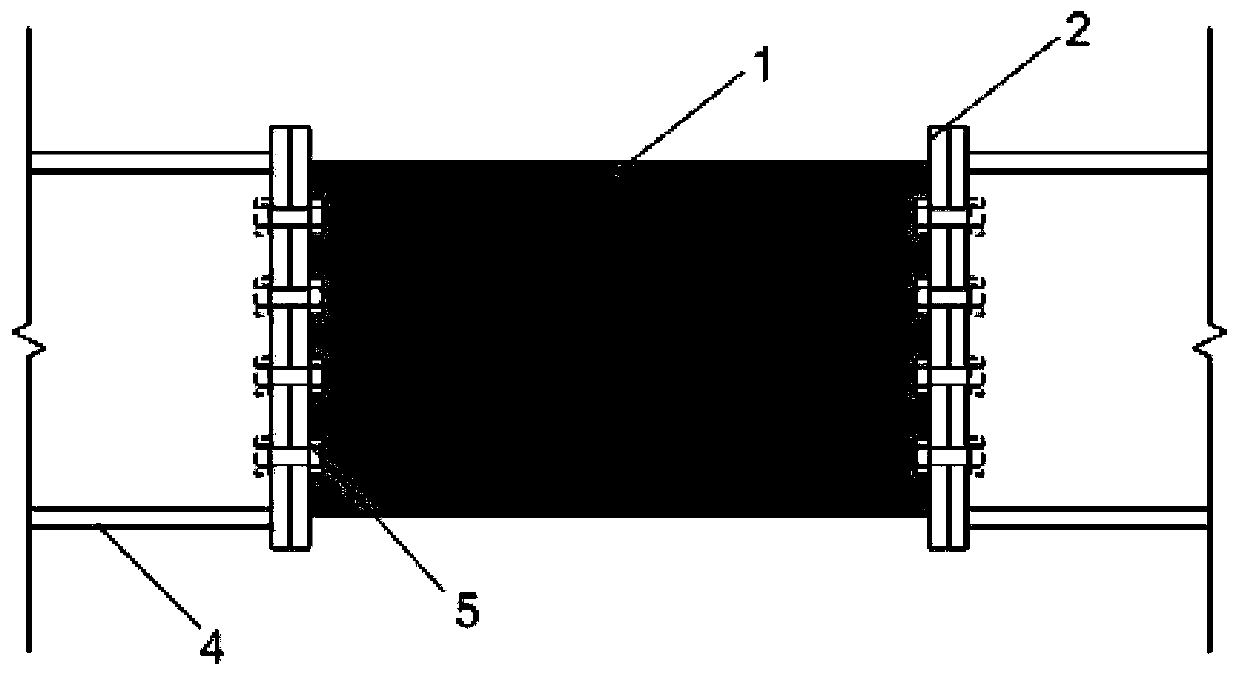

[0024] Further, such as figure 2 As shown, after the corrugated steel plate 1 and the connecting plate 2 are welded as a whole, they are connected with the surrounding structural members by high-strength bolts 5, which is convenient for repair and replacement after the earthquake.

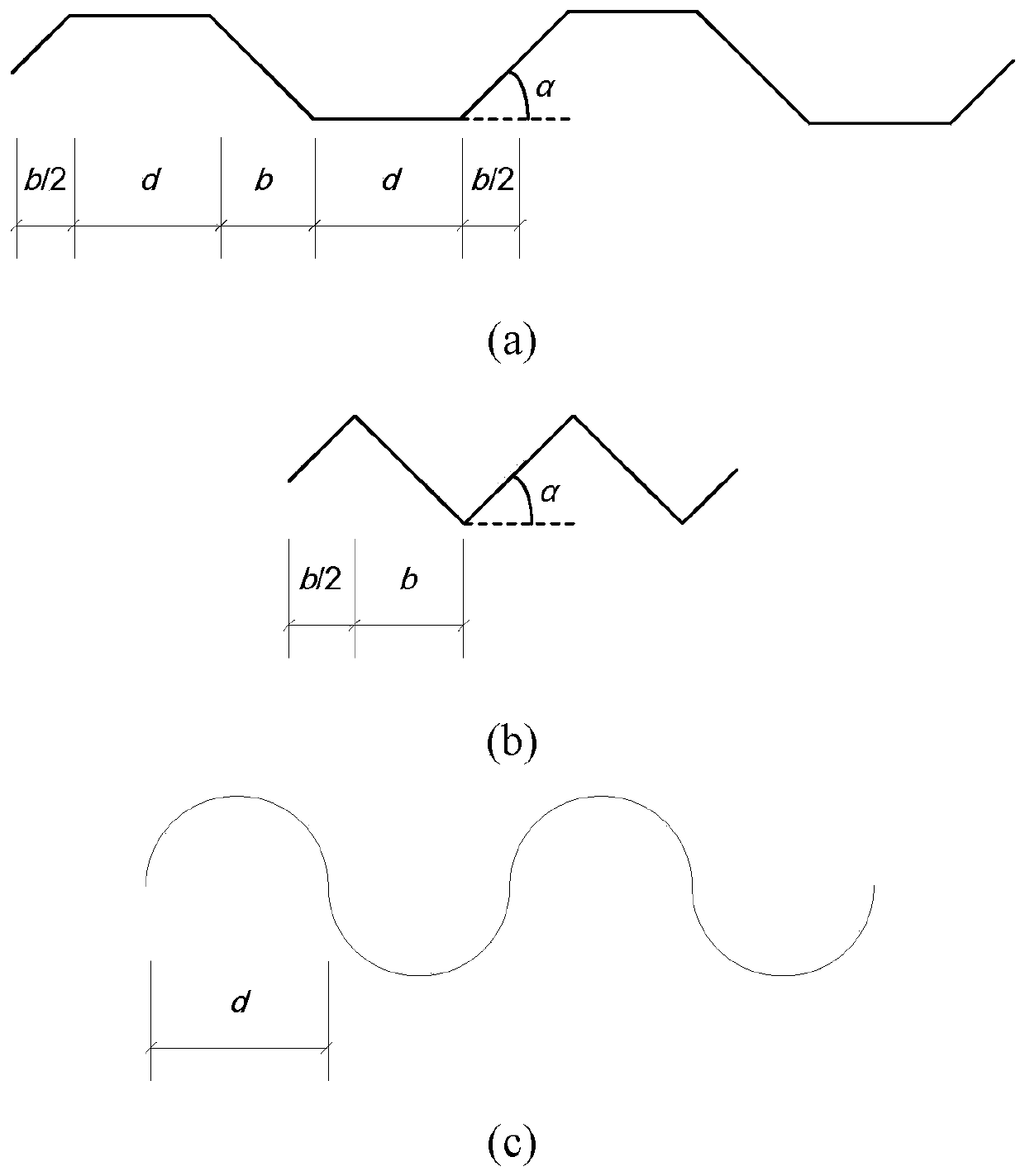

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com