A steel-concrete composite special-shaped lattice column

A technology of concrete columns and lattice columns, applied in the direction of columns, pillars, pier columns, etc., can solve problems such as deformation, time-consuming assembly, and impact on structural quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

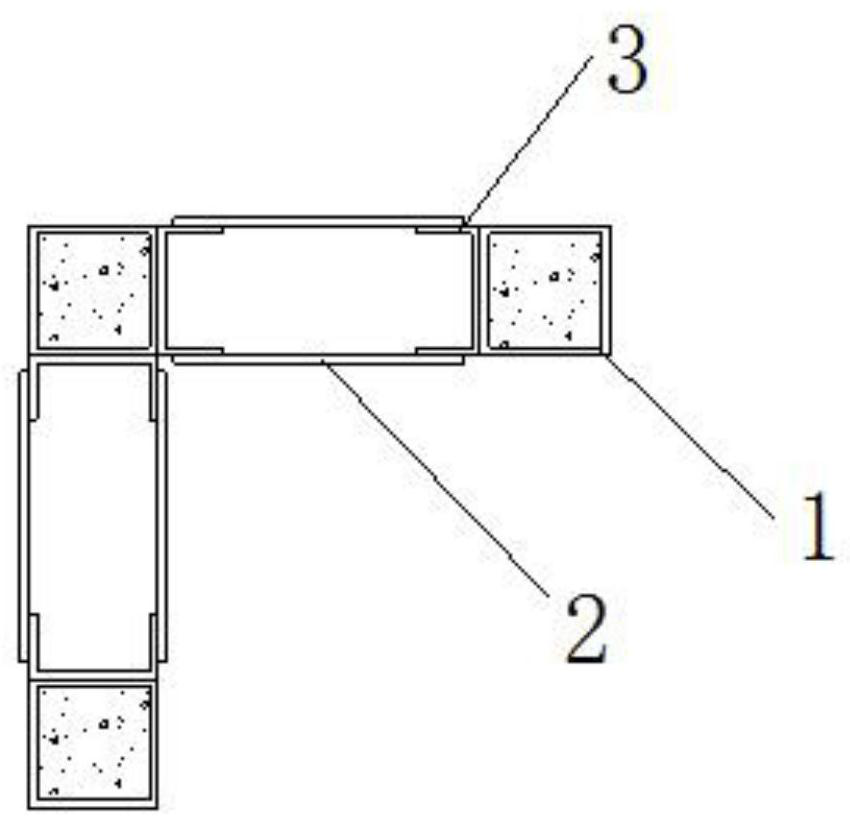

[0095] The present invention is a new type of steel-concrete combined special-shaped lattice column, which is composed of square steel pipe concrete column 1, channel steel 2, and strip 3, and adopts the form of type I "L" combined special-shaped lattice column. The sectional view is as attached figure 1 shown.

[0096] The square concrete-filled steel tube column 1 is a seamless square steel tube, and ordinary concrete C30 is poured inside, and it can also be any one of lightweight aggregate concrete or high-performance concrete, not limited to the above types.

[0097] There are four rows of first reserved holes along the length of the column on the square steel tube concrete column for the passage of bolts;

[0098] The channel steel 2 connected with the square steel tube concrete column 1 has high-strength bolt rods welded on its web plate, and four rows of high-strength bolt rods are arranged along the length direction of the channel steel. The reserved four rows of firs...

Embodiment 2

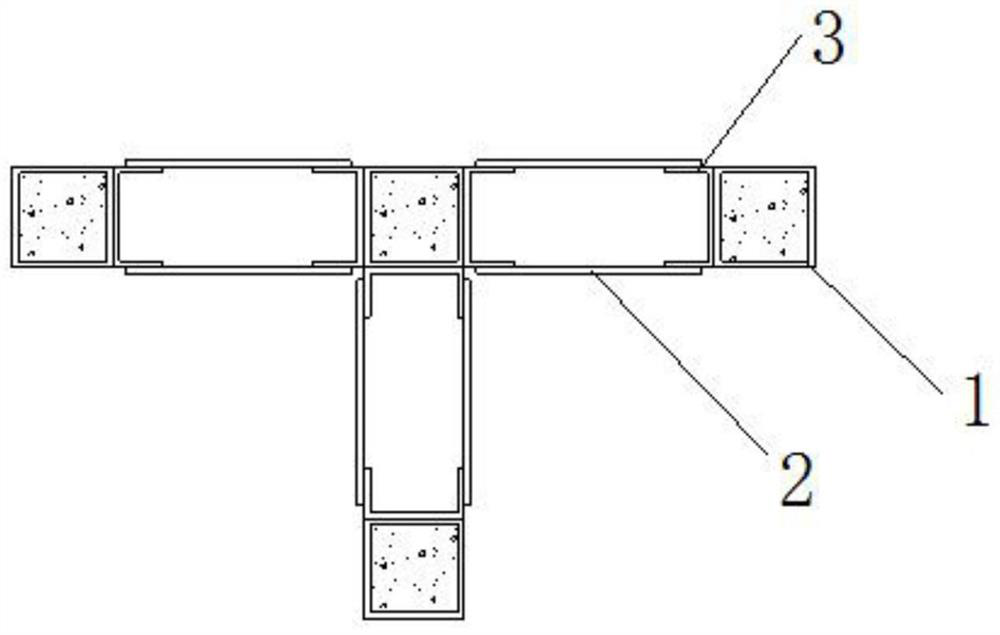

[0214] The difference from Example 1 is that Type I "T"-shaped composite special-shaped lattice column is adopted, and the cross-sectional view is shown in the attached figure 2 shown.

[0215] Lightweight aggregate concrete is poured inside the square steel tube concrete column 1 .

[0216] The steel of the combined special-shaped lattice column is selected from low-alloy high-strength structural steel Q390 grade.

[0217] All the other are identical with embodiment 1.

Embodiment 3

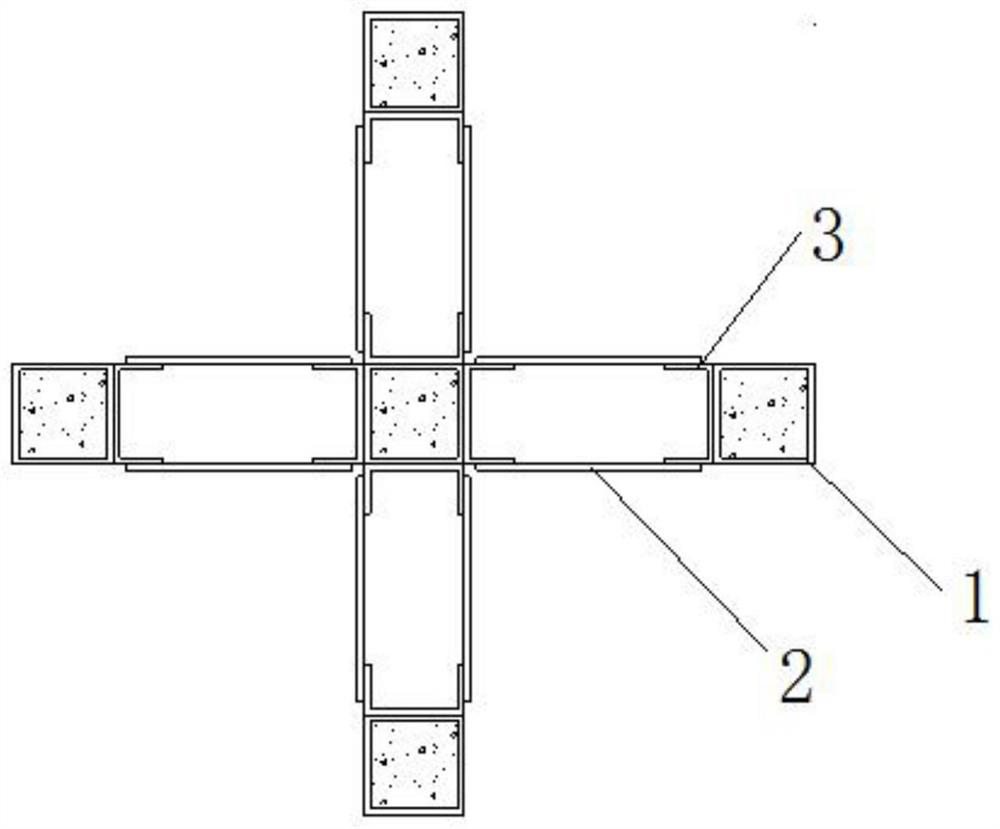

[0219] The difference from Example 1 is that the type I "ten"-shaped combined special-shaped lattice column is adopted, and the cross-sectional view is shown in the attached image 3 shown.

[0220] High-performance concrete is poured inside the square concrete-filled steel tube column 1 .

[0221] The steel of the combined special-shaped lattice column is selected from low-alloy high-strength structural steel Q420 grade.

[0222] All the other are identical with embodiment 1.

[0223] From the above structure, the present invention adopts square steel pipes, channel steels, and trim strips, and the above raw materials can be prefabricated in factories, which is fast in processing, convenient in construction, and improves the efficiency in specific construction, and because the present invention adopts the above-mentioned The structure can provide a variety of cross-sectional forms, which can effectively improve its bearing capacity and seismic performance while adapting to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com