A kind of grouting device and grouting method for floating pebble gravel stratum

A technology of gravel and floating eggs, applied in the field of curtain grouting, which can solve the problems of difficult formation of curtains, waste of materials, and reduced efficiency of construction equipment, and achieve the effects of meeting anti-seepage requirements, improving grouting efficiency, and saving grouting volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

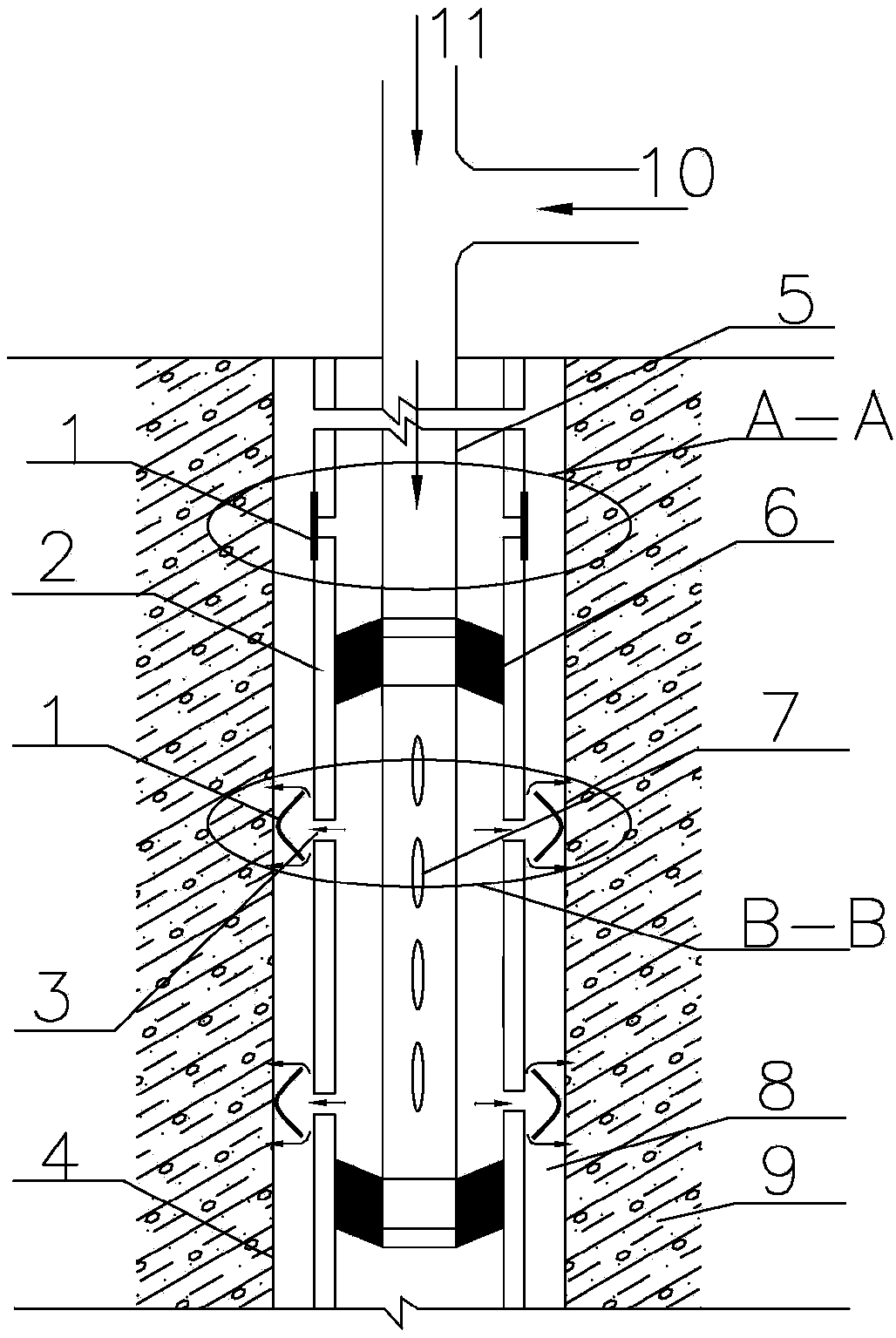

[0041] Such as figure 1 As shown, a grouting device for floating gravel formations in this embodiment includes an outer tube 2, an outer tube sealing device 1, an inner tube 5 placed inside the outer tube 2, and an inner tube sealing device 6. The inner pipe 5 is provided with two groups of inner pipe sealing devices 6, and the pipe section between the two groups of inner pipe sealing devices 6 is the inner pipe slurry outlet section, and the inner pipe slurry outlet 7 is distributed on the inner pipe slurry outlet section. The outer tube 2 is provided with a plurality of directional opening groups along its axial direction, and the distance between two adjacent directional opening groups along the axial direction of the outer tube 2 is 30-40 cm,

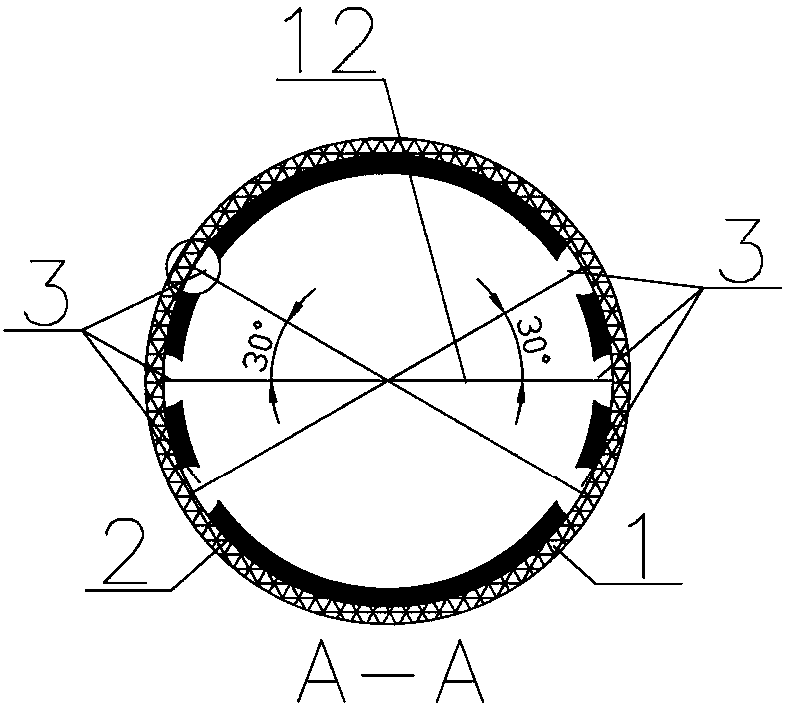

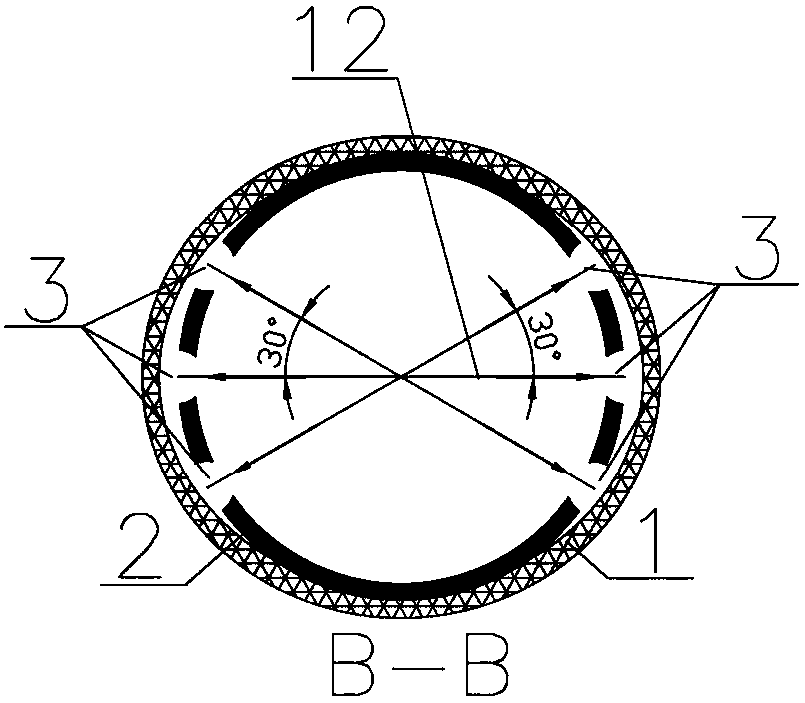

[0042] Such as figure 2 As shown, each directional opening group includes 3 pairs of directional openings 3 distributed around the same outer tube 2, a total of 6 directional openings 3, and each pair of directional openings 3 is ...

Embodiment 2

[0054] This embodiment is a kind of grouting method that is used for floating pebble gravel stratum, adopts the grouting device described in embodiment 1 to carry out grouting, as Figure 6-7 As shown, it is a schematic diagram of the application of the grouting method in this embodiment to the curtain lapping anti-seepage of the embankment 17. The embankment 17 is perpendicular to the river, and the seepage direction 14 of the flowing water 16 in the floating pebble gravel formation of the embankment 17 is perpendicular to the embankment 17 at the same time. Lap direction 15 with curtain.

[0055] The grouting method includes a tube lowering step and a curtain overlapping step. In the tube lowering step, when the outer tube is put into the drilled hole, the basic radial direction 12 is parallel to the curtain pre-lapping direction 15 .

[0056] The curtain lapping is divided into two steps:

[0057] Step 1: Drill a sequence of holes at intervals along the curtain lap direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com