Horizontal joint seam connecting structure suitable for thin panel extrusion deformation

A technology of extruding deformation and connecting structures, which is applied in dams, water conservancy projects, sea area projects, etc., can solve problems such as damage and bending deformation of steel bars, and achieve the effects of avoiding panel damage, reducing deformation degree, and reducing displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

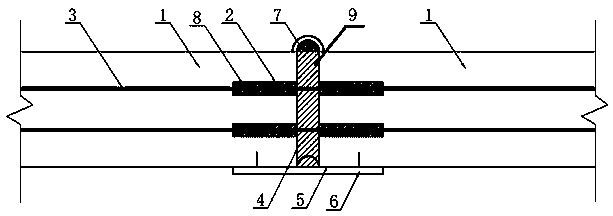

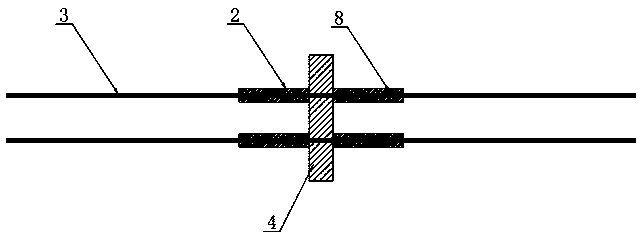

[0025] In order to overcome the problems that the thin panels near the existing horizontal joints are severely damaged and the steel bars are bent and deformed, the present invention provides such as figure 1 and 2 As shown in the horizontal joint connection structure adapting to the extrusion deformation of thin panels, the present invention sets a steel sleeve at the horizontal joint, and fills the steel sleeve with asphalt hemp wire, so that the steel bars near the horizontal joint are separated from the concrete and can be opposed to each other. A rubber backing plate is set at the bottom of the horizontal seam, a water-stop copper sheet is set on the rubber backing plate, and the upstream surface of the panel is blocked by a surface water-stopping structure. The invention can not only meet the anti-seepage requirements, but also significantly reduce the possibility of damage near the horizontal joint due to the extrusion of the faceplate, and ensure the safe operation of ...

Embodiment 2

[0032] On the basis of Embodiment 1, in this embodiment, the number of the reinforcing bars 3 is at most two.

[0033] The length of the steel casing 2 is 1m.

[0034] The thickness range of the concrete panel 1 is: 30cm-100cm.

[0035] The bottom of the concrete panel 1 is provided with a backing plate 6 , the backing plate 6 is located at the horizontal seam 9 , and the backing plate 6 is located below the water-stop copper sheet 5 .

[0036] The backing plate 6 is a rubber backing plate.

[0037] The diameter of the steel sleeve 2 is 1.1 times that of the steel bar 3 . The diameter of the steel sleeve 2 is larger than the diameter of the rebar 3, so that the rebar 3 can be moved in the steel sleeve 2.

[0038] The width of the horizontal slit 9 is 1-2 cm.

[0039] The thickness of the water-stop copper sheet 5 is 1.2 mm.

[0040] The joint filling material 4 is a composite asphalt filling material.

[0041] In the present invention, a horizontal joint 9 is arranged be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com