A prefabricated special-shaped vierendeel pile for deep foundation pit support structure and its construction method

A deep foundation pit support and prefabrication technology, which is applied in the direction of foundation structure engineering, excavation, sheet pile walls, etc., can solve the problems that the trenching equipment cannot enter the construction site, increase the construction period and cost, and a large number of environments, so as to improve labor efficiency. Conditions, low comprehensive project cost, and the effect of meeting the anti-seepage requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

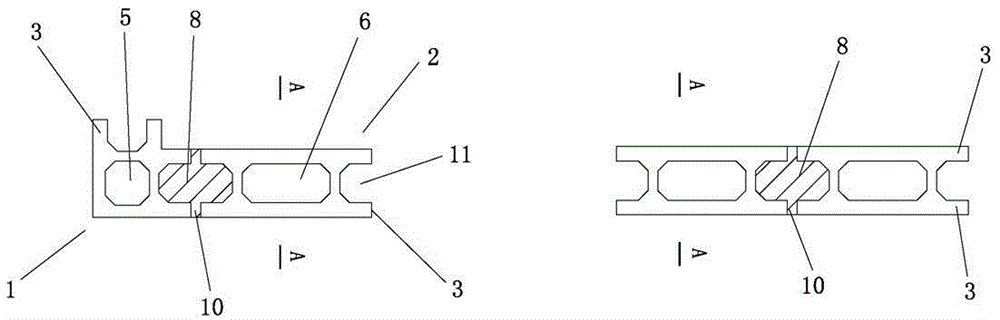

[0027] A kind of prefabricated special-shaped hollow pile and construction method thereof for deep foundation pit supporting structure described in the present invention, such as figure 1 -Shown in -15, the described prefabricated special-shaped vierendeitoid pile comprises a prefabricated special-shaped Vierendeoid pile 1 and a strip-shaped prefabricated special-shaped Vierendeoid pile 2 containing right-angled sides; the prefabricated special-shaped Vierendeoid piles containing right-angled sides are each spaced at its two vertical ends There are two cantilevered walls 3, the end of the cantilevered walls 3 is reserved for welding steel plate 4, and the vertical hollow 5 is provided at the right angle; An empty stomach 6, two hanging walls 3 are arranged at intervals at both ends, steel plates 4 are reserved for welding at the ends of the hanging walls 3; the prefabricated special-shaped hollow pile 1 and the strip prefabricated special-shaped hollow pile 2 containing right-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com