A full-section quasi-three-grade long-age roller compacted concrete construction method

A technology of roller compacted concrete and construction methods, applied in filling, foundation structure engineering, construction, etc., can solve problems such as difficult to meet rapid construction of roller compacted concrete, difficult to guarantee concrete quality, unfavorable construction costs, etc., to achieve optimal construction methods , Reduce engineering investment and simple construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

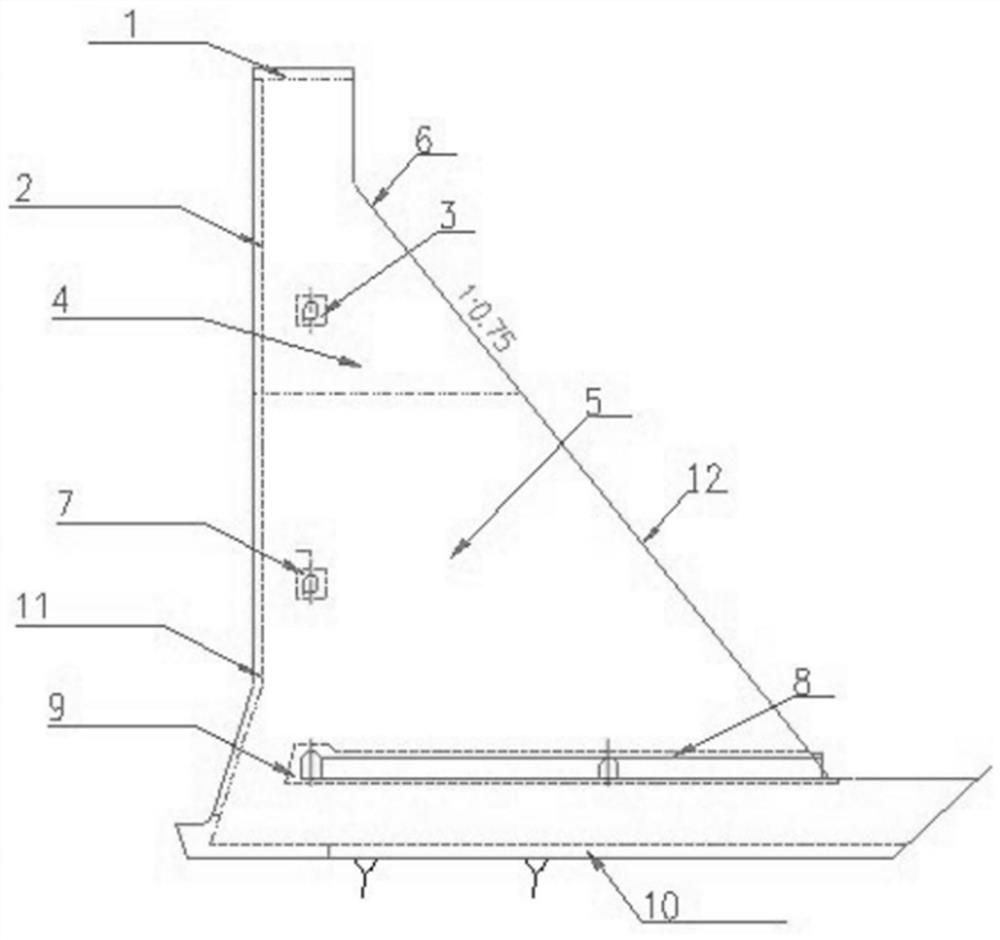

[0057] The present invention will be further described below in conjunction with the accompanying drawings and the specific implementation of concrete construction in the test section.

[0058] Roller compacted concrete dam building technology has the characteristics of fast and economical. Since the 1980s until now, the roller compacted concrete dam building technology has been perfected day by day, but some construction techniques still need to be continuously improved to meet the requirements of the RCC dam building technology. Requirements for rapid construction and quality compliance.

[0059] During the construction of roller compacted concrete dams at home and abroad, there are many types of concrete in the dam body, especially the secondary anti-seepage concrete at the upstream and downstream formwork positions, the surrounding corridors of the dam body, the left and right banks, the bank slopes on both sides, and the reserved holes. Metamorphic concrete needs to be co...

Embodiment 2

[0121] Embodiment 2: Construction method of full-section quasi-three-graded RCC. The method includes the following steps:

[0122] a. Base surface treatment, flushing and cleaning the completed base surface.

[0123]The foundation surface that has been poured (including normal concrete and roller compacted concrete) is subjected to roughening treatment. The roughening machine of Gezhouba Group is used for roughening. The roughening pressure is adjusted to the range of 25MPa-35MPa. , the pressure of the flushing machine can be adjusted to 45MPa. When flushing, it is required to form a certain angle between the flushing gun and the concrete surface, and determine the effect of flushing, and then determine the pressure and angle of the flushing gun. The cement slurry and milk skin are all cleaned up, and the stones on the concrete surface are just exposed.

[0124] According to the comparison of the data in the test section, it can be seen that the flushing can be carried out 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com