A Construction Method of Metamorphic Concrete with Grouting at the Bottom

A technology of abnormal concrete and construction method, which is applied in basic structure engineering, construction and other directions, can solve the problems of inability to judge the vibrating effect of abnormal concrete, inability to guarantee the uniformity of grouting, unfavorable cost saving and construction period, etc., to optimize the construction method, The effect of reducing engineering investment and simple construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

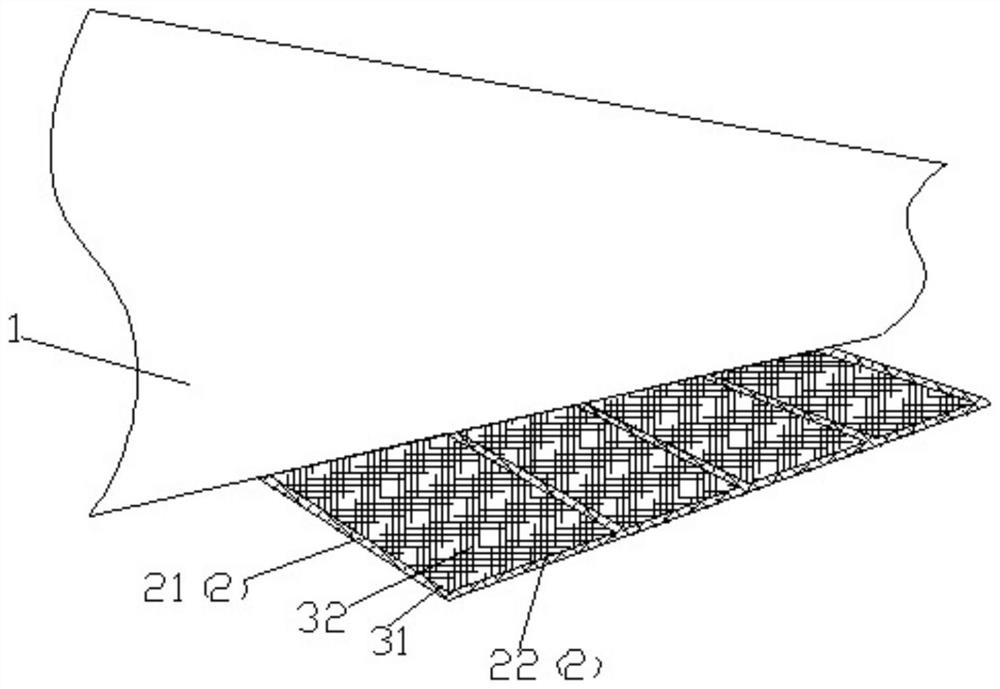

Image

Examples

Embodiment 1

[0070] This embodiment 1 is about the construction method of three-graded metamorphic concrete in the upstream of the simulated roller compacted concrete gravity dam in the test section. The method includes the following steps:

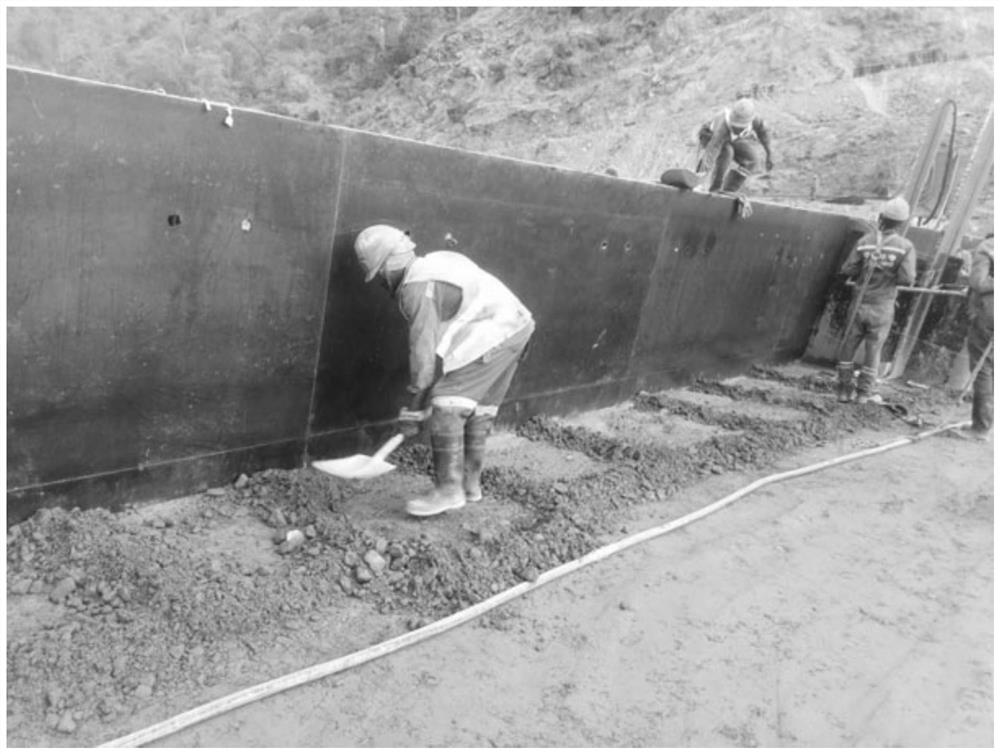

[0071] (1) Base surface treatment

[0072] The foundation surface that has been poured (including normal concrete and roller compacted concrete) is subjected to roughening treatment. The roughening machine of Gezhouba Group is used for roughening. The roughening pressure is adjusted to the range of 25MPa-35MPa. , the pressure of the flushing machine can be adjusted to 45MPa. When flushing, it is required to form a certain angle between the flushing gun and the concrete surface, and determine the effect of flushing, and then determine the pressure and angle of the flushing gun. The cement slurry and milk skin are all cleaned up, and the stones on the concrete surface are just exposed.

[0073] (2) To build the stem, use the roller compacted concrete ...

Embodiment 2

[0080] Example 2: Regarding the construction method of the three-graded metamorphic concrete upstream of the dam roller compacted concrete gravity dam. The method includes the following steps:

[0081] Foundation surface treatment: The foundation surface that has been poured (including normal concrete and roller compacted concrete) is subjected to roughening treatment. Gezhouba Group's wool flushing machine is used for flushing, and the flushing pressure is adjusted to the range of 25MPa-35MPa. For high concrete surfaces, the pressure of the flushing machine can be adjusted to 45MPa. When flushing, it is required to form a certain angle between the flushing gun and the concrete surface, and determine the effect of flushing, and then determine the pressure and angle of the flushing gun, and the requirements for flushing Clean up all the cement slurry and milk skin on the concrete surface, and just expose the stones on the concrete surface.

[0082] According to the comparison ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com