Pavement paving equipment for mine roadways

A paving and roadway technology, applied in roads, roads, buildings, etc., can solve the problems of high labor intensity of workers, inability to pass pedestrians and traffic, and inconvenient pedestrians to walk, so as to avoid waste of resources, fast and accurate paving, and fast The effect of paving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

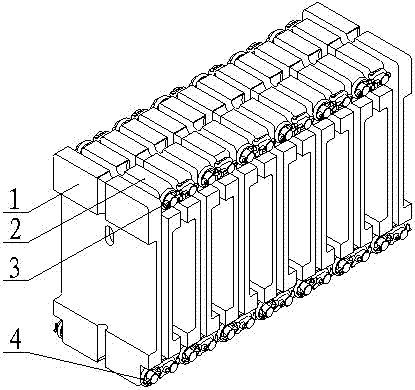

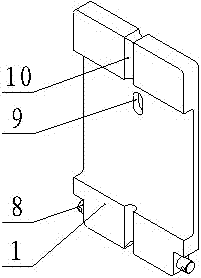

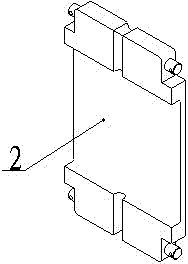

[0015] Such as figure 1 As shown, the roadway pavement equipment of the present invention is mainly composed of a terminal paving template 1 and a foldable paving template 2; the terminal paving template 1 is two pieces, which are symmetrically arranged on both sides; The foldable paving template 2 is a plurality of blocks, all of which are made into standard templates of the same size, and the number of foldable paving templates 2 is determined according to the road section of the underground roadway. Two end paving formworks 1 are respectively hinged on both sides of multiple foldable paving formworks 2, and connecting columns 8 are arranged symmetrically on one side of end paving formwork 1 and on the upper and lower sides of multiple foldable paving formworks 2 ;Such as Figure 5 As shown, in order to adapt to the underground turning roadway, it is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com