Heating floor master systems and heating components for floors or walls

A technology of heating components and heating boards, which is applied in the field of architectural decoration and can solve problems such as low thermal efficiency, high requirements, and poor comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] (Example 1, heating element for floor or wall)

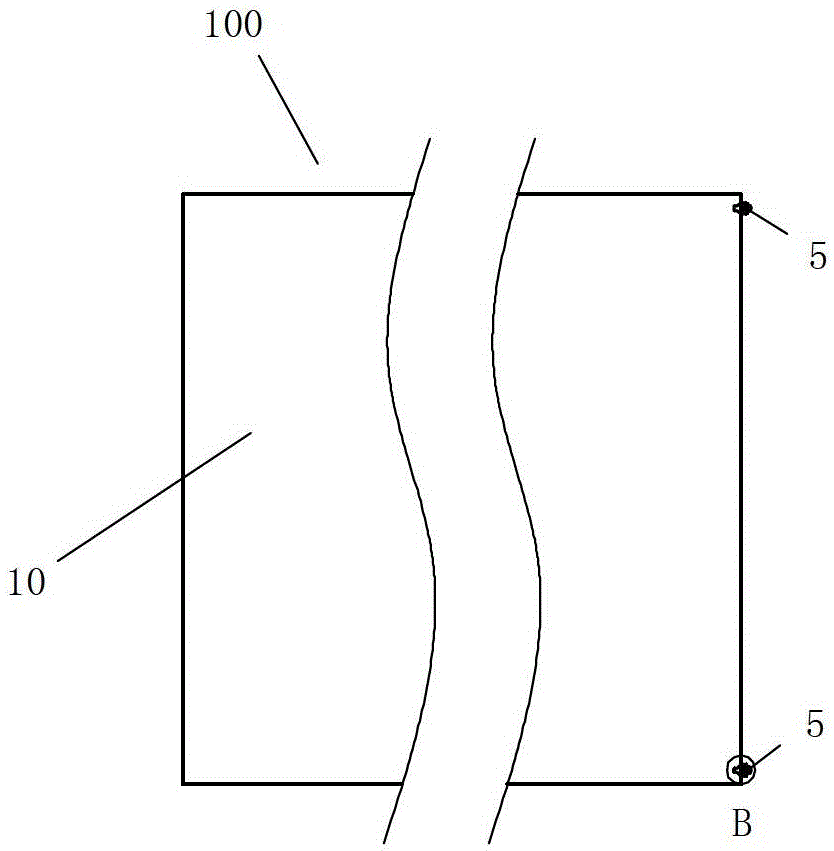

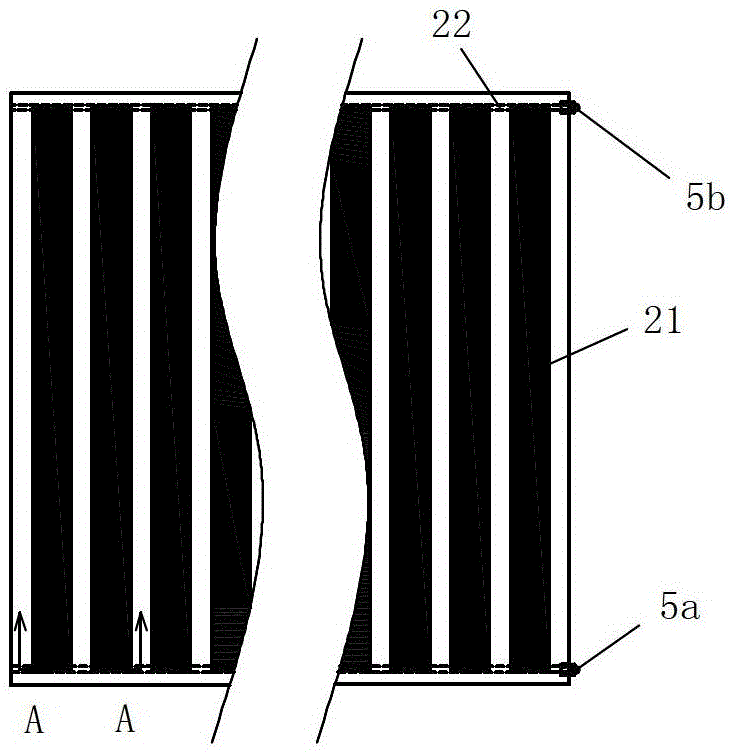

[0086] See figure 1 and image 3 , the heating component 100 of the present invention includes a heating plate 10 and a socket 5 . The socket 5 is composed of a front socket 5a (right front in this embodiment) and a rear socket 5b (right rear in this embodiment) located on the same side of the left and right sides of the heating plate 10 .

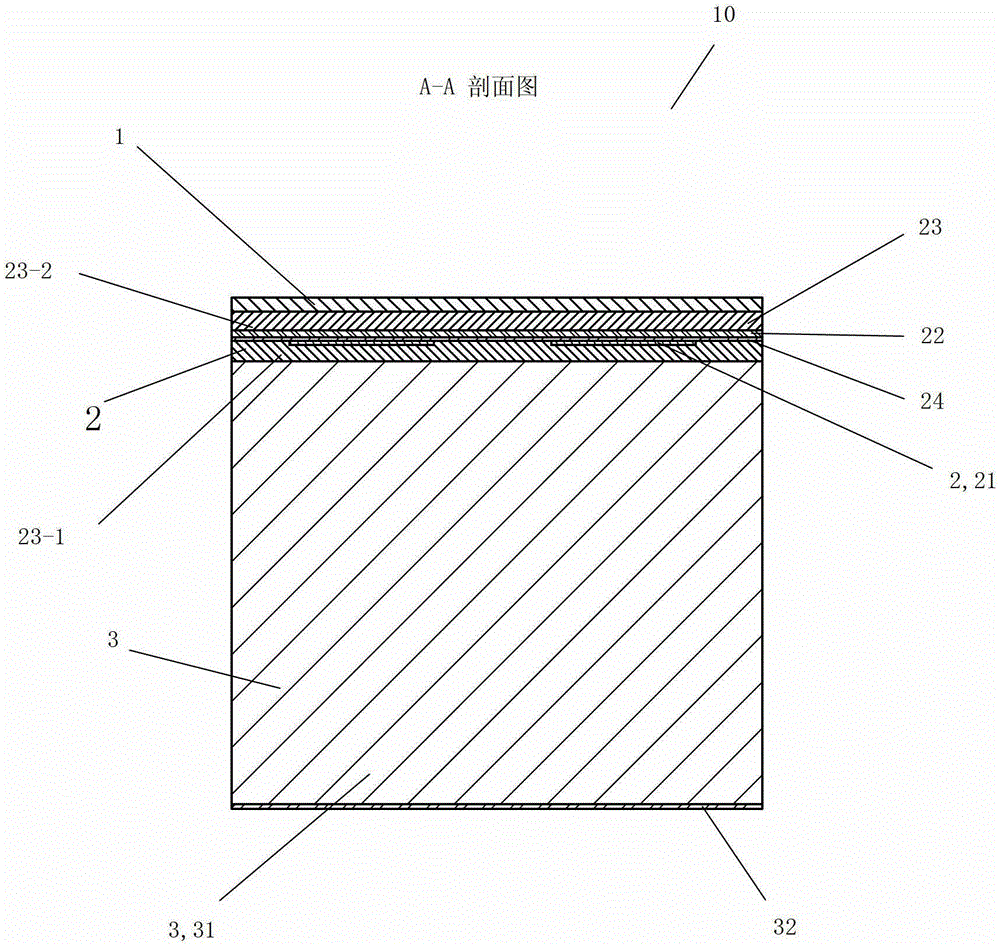

[0087] See Figure 1 to Figure 3 , the heating plate 10 includes a release paper 1 , a heating layer 2 and a bottom layer 3 arranged in order from top to bottom.

[0088] See Figure 2 to Figure 5 , the heating layer 2 is an electric heating film. The length of the electric heating film 2 in the front and rear directions is 15 cm to 200 cm (100 cm in this embodiment), the length in the left and right directions of the electric heating film 2 is 5 meters to 200 meters (20 meters in this embodiment), and the electric heating film 2 is The sheet-like electric heating device is comp...

Embodiment 2

[0108] (Example 2, heating element for floor or wall)

[0109] See Figure 18 to Figure 21 , the rest of this embodiment is the same as that of Embodiment 1, except that the lower clamping device 54a of the bottom plate 54 of the socket 5 is a bead 54a-2. There are 1 to 4 pressing bars 54a-2 (two in this embodiment), and each pressing bar 54a-2 has the same structure and shape. It is arranged in the front-rear direction and penetrates the upper side of the bottom plate 54. on the triangle.

[0110] The upper clamping device 55b of the pressing plate 55 of the socket 5 is a pressing bar 55b-2. There are 1 to 4 pressing bars 55b-2 (two in this embodiment), and each pressing bar 55b-2 has the same structure and shape, is arranged in the front-rear direction and penetrates the lower side of the pressing plate 55. upside down triangle.

Embodiment 3

[0111] (Example 3, heating floor main system)

[0112] See Figure 17 , the main heating floor system of this embodiment includes a PVC floor 200 and heating components. The heat-generating component adopts the heat-generating component 100 described in Embodiment 1. The PVC floor is also called the polyvinyl chloride floor. The PVC floor 200 is in the shape of a rectangle as a whole, and its length and width are determined as needed, and the front and rear length of the heating element 100 is an integer multiple of the width of the PVC floor 200 (this application example uses Guangzhou The brand supplied by City Jinkun Decoration Engineering Co., Ltd. is the PVC floor of the Nabaili new life wood grain series. The size of the PVC floor can be customized according to the requirements. 250 mm).

[0113] See Figure 17 , when laying the main heating floor system of this embodiment, firstly, the heating components 100 that have been manufactured in the left-right direction ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com