Treatment method of peat soil dam foundation

A treatment method, peat soil technology, applied in soil protection, infrastructure engineering, construction, etc., can solve problems such as environmental impact, odor, leakage, etc., and achieve the effects of construction quality assurance, fluidity reduction, and construction cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

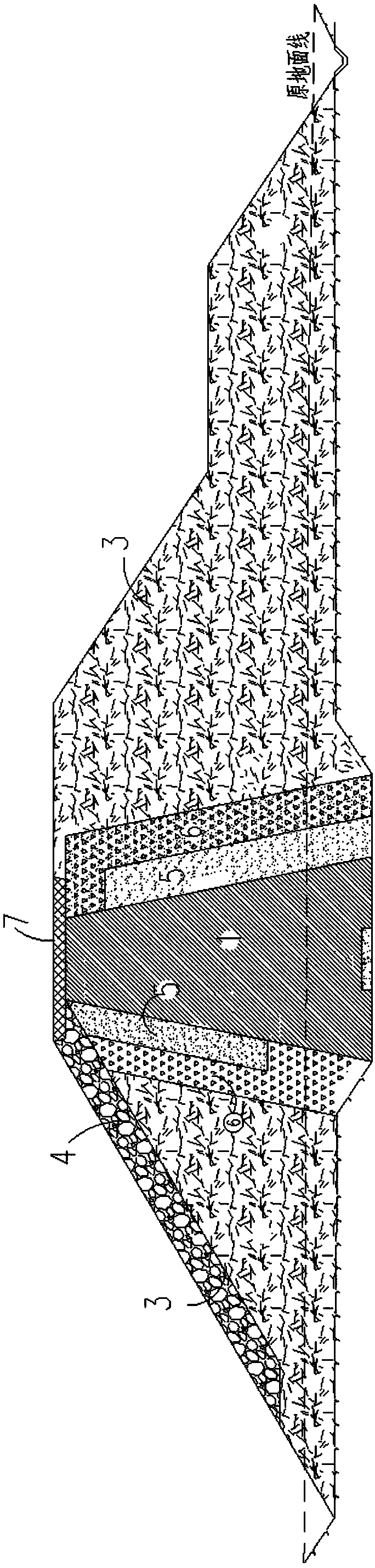

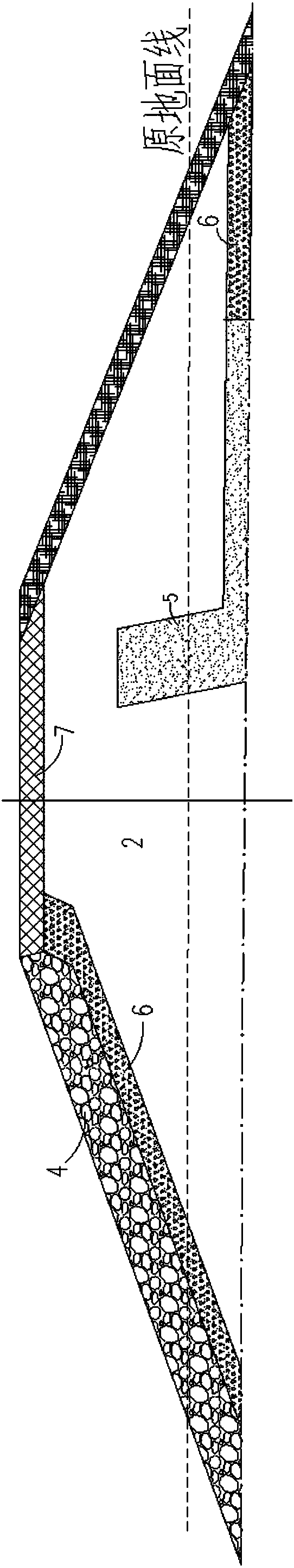

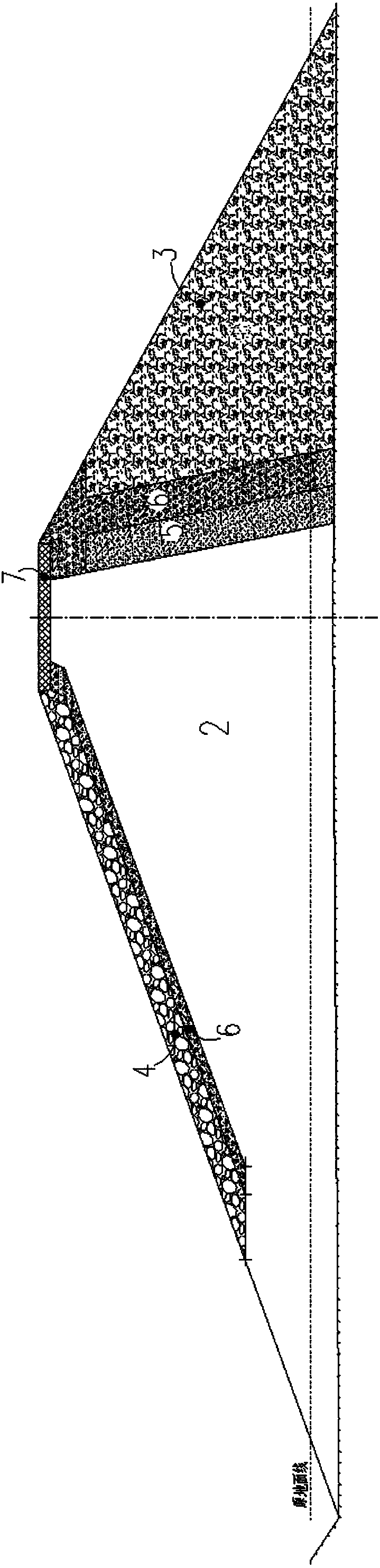

[0031] The present invention will be described in further detail below in conjunction with accompanying drawings and specific embodiments, and this embodiment is a construction example of the dam of the Cote d'Ivoire Soubre hydropower station.

[0032] 1) The dam foundation treatment method for the dam section of the clay core rockfill dam with extremely high soil moisture content, weak soil quality and low bearing capacity near the spillway is as follows:

[0033] Peat soil treatment: Throw gravel at the dam foundation to increase the bearing capacity and strengthen the foundation.

[0034] The dam section is close to the spillway, and the dam type is a clay core rockfill dam, which has high requirements for the dam foundation. The exploration pit shows that the upper layer of the dam foundation here is a swamp, and the lower layer is a residual soil layer and a bedrock surface. The swamp layer is thinner and smaller in scope, and the swamp soil is in a fluid state in rainy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com