Tunnel lining end template structure with waterproofing and drainage functions

An end formwork, waterproof and drainage technology, which is applied in the direction of tunnel lining, drainage, tunnel, etc., can solve the problems of inaccurate positioning of buried waterstops for lining concrete, unsatisfactory waterproof and drainage construction quality, irregular formwork, etc. , to achieve the effect of improving the integrity and waterproof and drainage performance, reducing the risk of water leakage and meeting the requirements of anti-seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

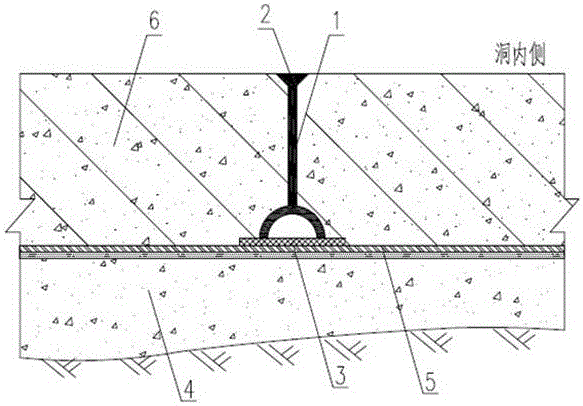

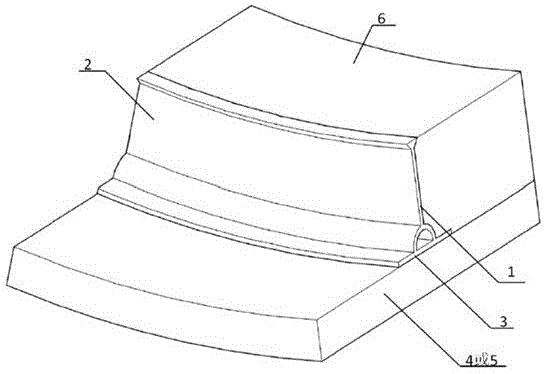

[0021] Such as figure 1 , 2 As shown, a tunnel lining end formwork structure with water-proof and drainage functions, including a positioning pad 3 arranged on the surface of the tunnel primary support 4 or waterproof board 5 and an end formwork located at the lining construction joint 2 of the secondary lining 6 1. It is characterized in that: one end of the end template 1 close to the inner side of the tunnel is a seam-riding belt, and the other end is a drainage groove, and the opening end of the drainage groove is sealed by a positioning pad 3 to form a seepage diversion channel.

[0022] The cross-section of the seam riding belt is trapezoidal, and the lower bottom of the trapezoidal shape is close to the inner side of the tunnel.

[0023] The drainage groove is a semicircular groove.

[0024] The end template 1 is a strip-like structure prefabricated by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com