Gas axial isolation belt in tunnel gas accumulation area and construction method thereof

A technology for gathering areas and isolation zones, which is applied in tunnels, tunnel linings, gas discharge, etc., can solve problems that are likely to cause major safety accidents and serious safety problems, reduce the risk of seepage and diffusion, and reduce the pressure of gas seepage prevention Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

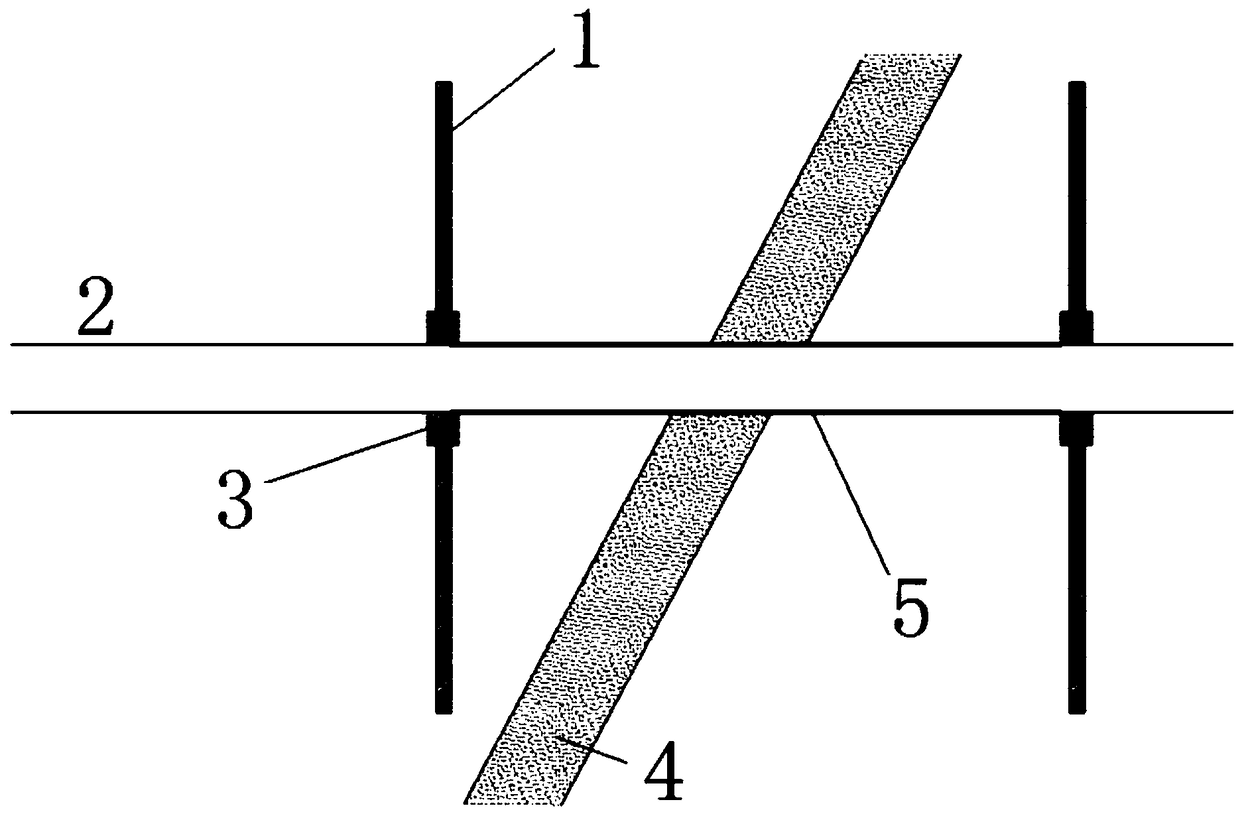

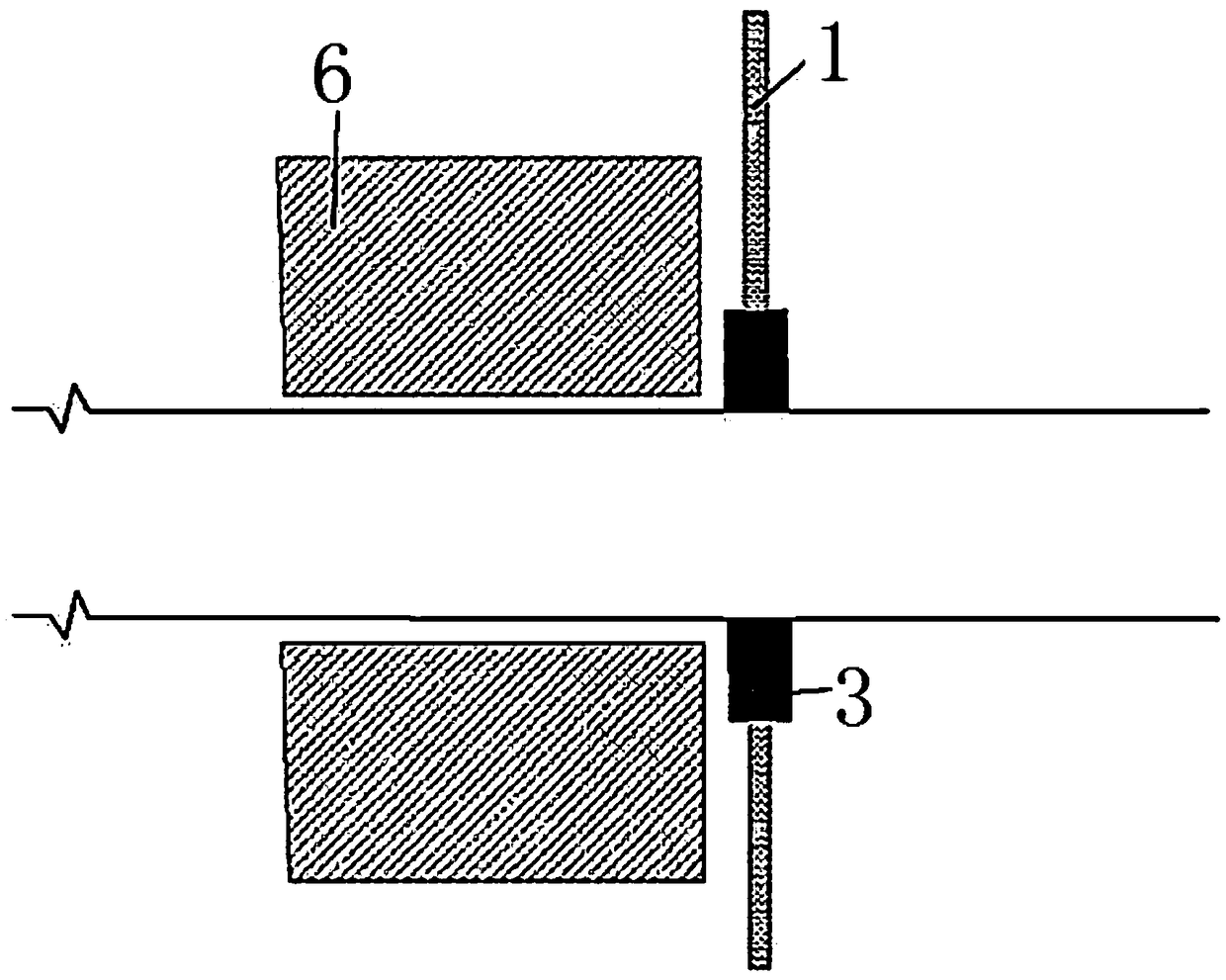

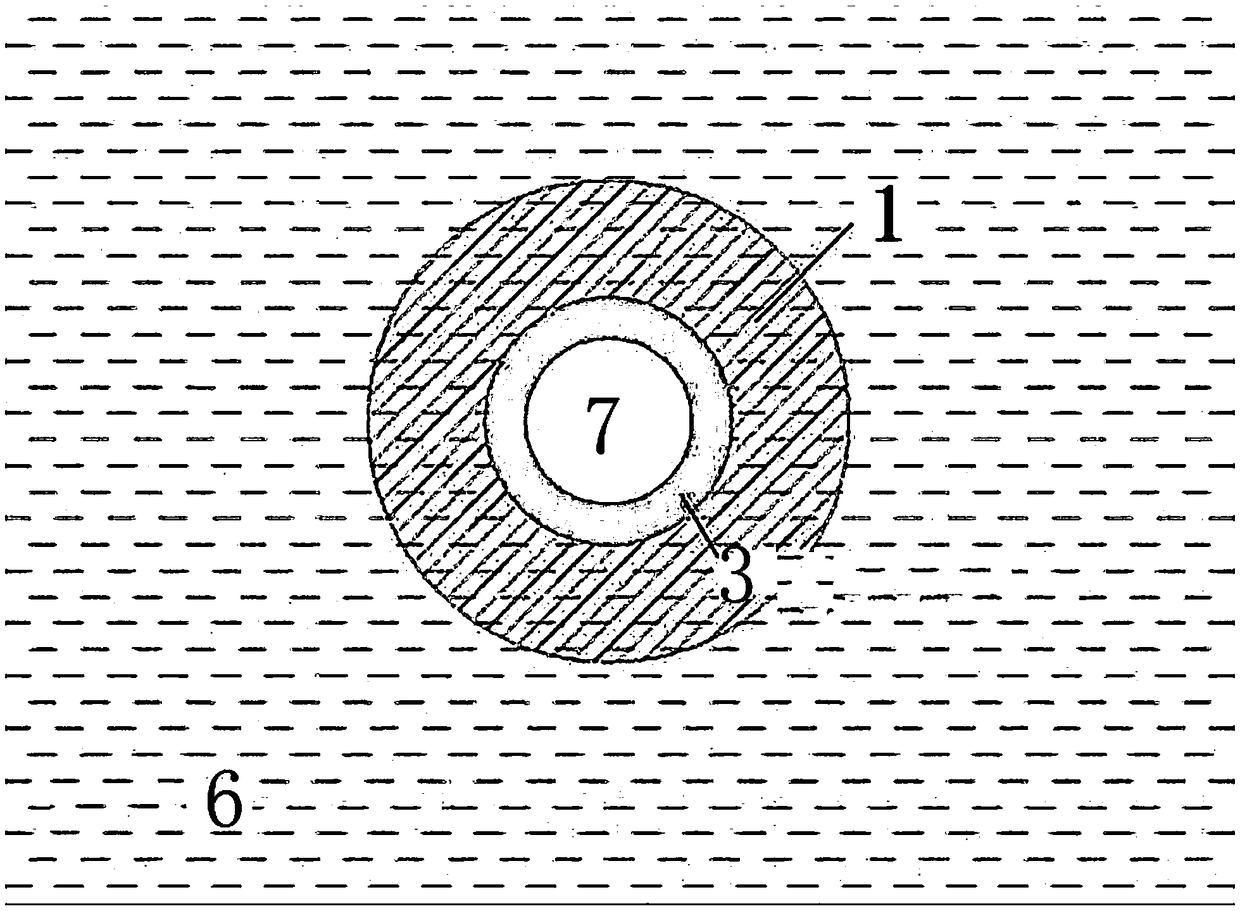

[0034] see Figure 1-Figure 5 , a gas axial isolation zone in the gas accumulation area of the tunnel, drawing on the concept of partition waterproofing in tunnel waterproofing, in the gas seepage prevention construction, a structure similar to a water stop is constructed to separate the high gas coal seam from the Generally separated by strata, it includes a regional grouting zone 1 and a gas isolation ring 3, both of which are set outside the head and tail of the tunnel 7, and the tunnel 7 is excavated in the coal seam where gas has accumulated 4, the high gas support 2 is applied at the initial position of the tunnel 7, and the anti-seepage support 5 of the coal penetration section is implemented at the end position of the tunnel 7.

[0035] Circumferential excavation is carried out on the outside of the beginni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com