Construction method for inserting impermeable blankets in cement-soil continuous wall to form composite curtain and composite curtain prepared with construction method

A construction method and cement-soil technology, applied in the field of composite curtains, can solve problems such as potential safety hazards in foundation pit engineering, ground disturbance, and curtain penetration cracks, and achieve the effects of not being easy to land subsidence, saving engineering costs, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

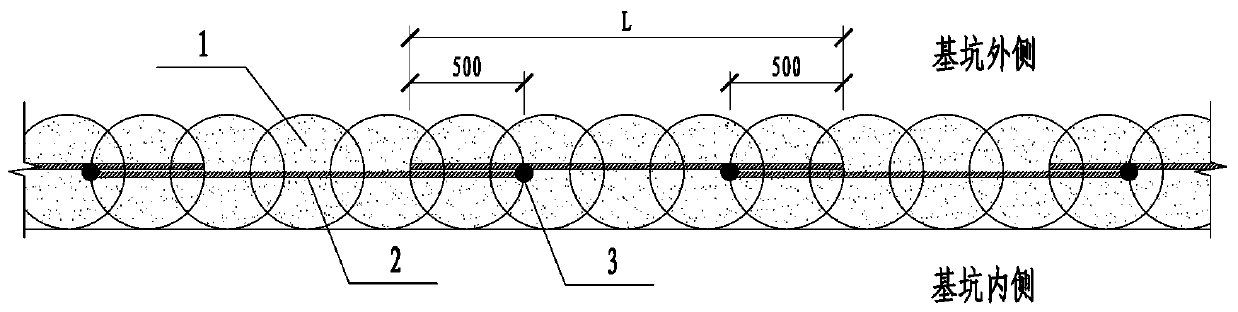

[0032] A construction method for inserting an anti-seepage blanket into a cement-soil continuous wall to form a composite curtain, comprising the following steps:

[0033] (1) Construct the cement-soil mixing pile according to the conventional method, the pile diameter is 500mm, the interlocking width between the piles is 150mm, and the depth is 20m;

[0034] (2) Before the initial setting of the cement-soil mixing pile that has been constructed, insert the first piece of anti-seepage blanket into the constructed cement-soil mixing pile from the thickness centerline of the top of the cement-soil mixing pile along the depth direction of the cement-soil mixing pile , the insertion depth of the anti-seepage blanket is equal to the depth of the cement-soil mixing pile (that is, the length of the anti-seepage blanket along the depth direction of the cement-soil mixing pile is the same as the depth of the cement-soil mixing pile);

[0035] (3) Insert the anti-seepage blanket while c...

Embodiment 2

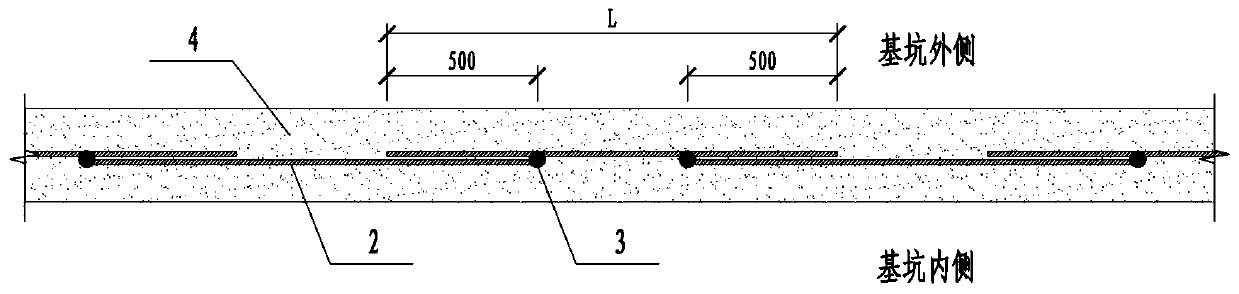

[0040] A construction method for inserting an anti-seepage blanket into a cement-soil continuous wall to form a composite curtain, comprising the following steps:

[0041] (1) Adopt TRD construction method (construction method of channel-cut cement-soil diaphragm wall) to construct channel-cut cement-soil diaphragm wall, the thickness of channel-cut cement-soil diaphragm wall is 550mm, and the depth is 25m;

[0042] (2) When the width of the constructed canal-cut cement-soil diaphragm wall meets the requirements for inserting the anti-seepage blanket, from the thickness centerline of the top of the canal-cut cement-soil diaphragm wall to the depth direction of the canal-cut cement-soil diaphragm wall Insert the first piece of anti-seepage blanket into the canal-cut cement-soil diaphragm wall under construction. The length is the same as the depth of the canal-cut cement-soil diaphragm wall);

[0043](3) Insert the anti-seepage blanket while continuing to construct the canal-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com