Manufacturing method for carbon-graphite floating ring

A carbon graphite, floating ring technology, applied in mechanical equipment, engine seals, engine components, etc., can solve the problems of increasing product leakage, large thermal expansion coefficient, shedding, etc., to achieve good comprehensive thermal expansion coefficient, good electrical conductivity, good air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

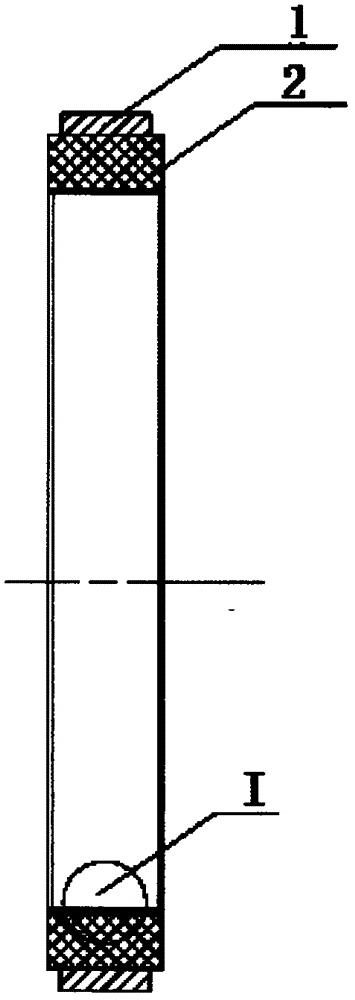

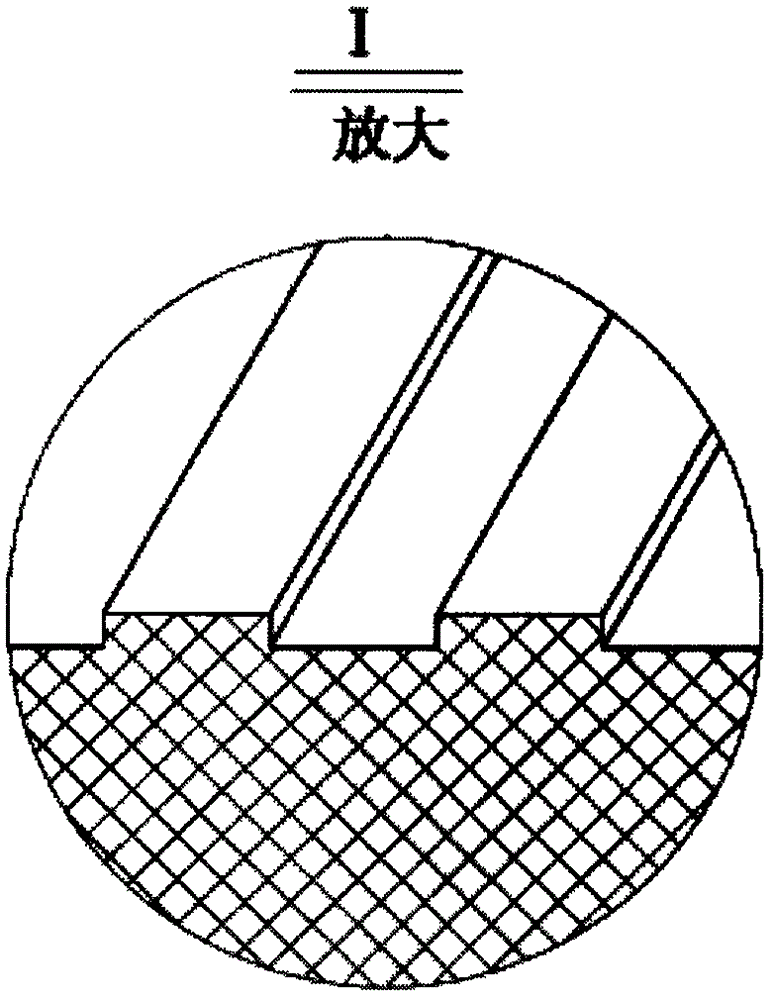

[0012] refer to figure 1 , figure 2 . The carbon-graphite floating ring 2 is composed of two parts. The carbon-graphite floating ring is wrapped with a metal ring 1 outside, the carbon-graphite sealing ring is inside, and the stainless metal ring 1 is outside. In order to form a gas film as soon as possible in the process of operation, and better play a sealing effect, the carbon graphite floating ring 2 can be formed with an annular small groove or a multi-thread. First process the carbon graphite floating ring and metal inlaid ring 1 with processing allowance, and use interference fit between the carbon graphite floating ring and metal inlaid ring 1. The size of the interference can be based on the size of the carbon graphite floating ring 2 product Adjust with the use temperature, such as the larger the size of the carbon graphite floating ring 2, the greater the interference, the higher the final use temperature, the higher the heating temperature of the metal insert ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com