Environment-friendly impervious concrete and preparation method thereof

An impermeable concrete, environment-friendly technology, applied in the field of asphalt concrete, can solve the problems of low impermeability and water resistance, reduce the service life of concrete, etc., and achieve the effects of guaranteed impermeability, compact structure, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

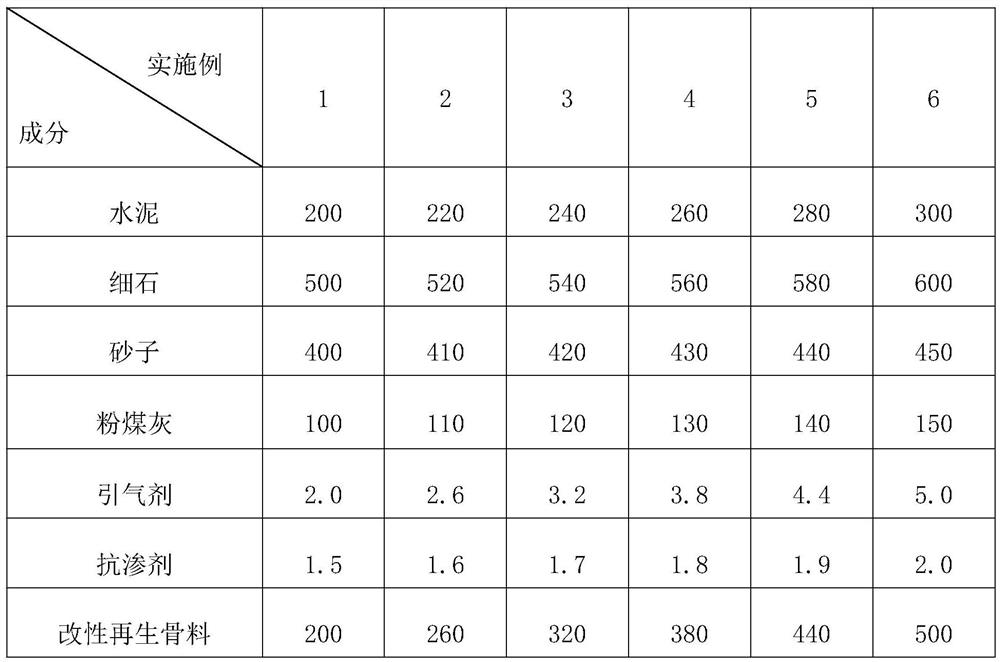

Examples

preparation example 1

[0059] A modified recycled aggregate, the preparation steps of which are as follows:

[0060] a. Pretreatment: first remove impurities and crush the waste concrete block, screen the crushed powder with a particle size of less than 15mm, then put it into the pickling solution with a pH of 3.0, heat it to 80°C under vacuum, and stir at 1000r / min 30min, obtained recycled aggregate;

[0061] The pickling solution is an aqueous solution of oxalic acid.

[0062] b. Modification treatment: put the recycled aggregate prepared in a into the modification solution at a weight ratio of 1:0.2, heat to 120°C and stir at 1000r / min for 30min, then freeze and dry at 0°C for 10min , and then carry out secondary crushing, and screen the crushed powder with a particle size of less than 20mm as the modified recycled aggregate;

[0063] The modified solution is composed of modified sol and modified filler in a weight ratio of 1:0.1;

[0064] The modified sol is composed of nano-scale silica sol,...

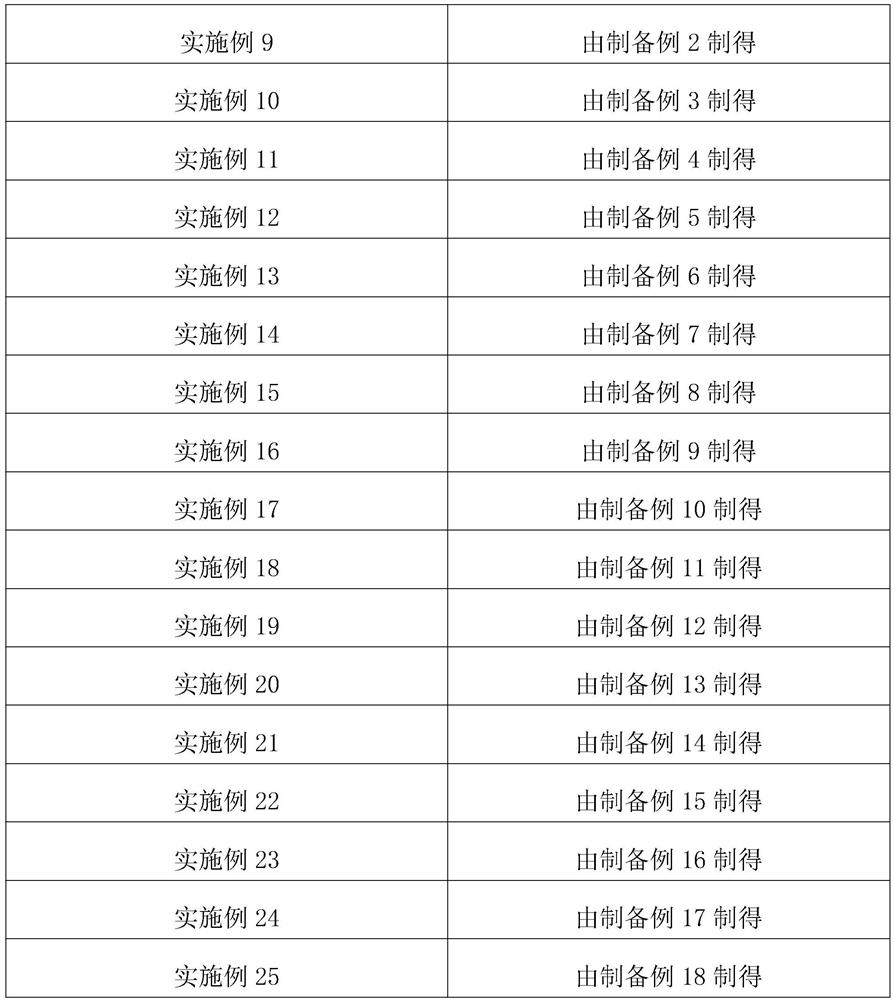

preparation example 2

[0067] A modified recycled aggregate, the difference from Preparation Example 1 is that the recycled aggregate prepared in a is put into the modified solution at a weight ratio of 1:0.3.

preparation example 3

[0069] A modified recycled aggregate, the difference from Preparation Example 1 is that the recycled aggregate prepared in a is put into the modified solution at a weight ratio of 1:0.4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com