PE pipe and production process thereof

A toughening and modification technology, applied in the field of PE pipe and its production process, can solve problems such as pipe wall leakage, achieve the effects of strengthening toughness, increasing heat insulation and impermeability, and good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

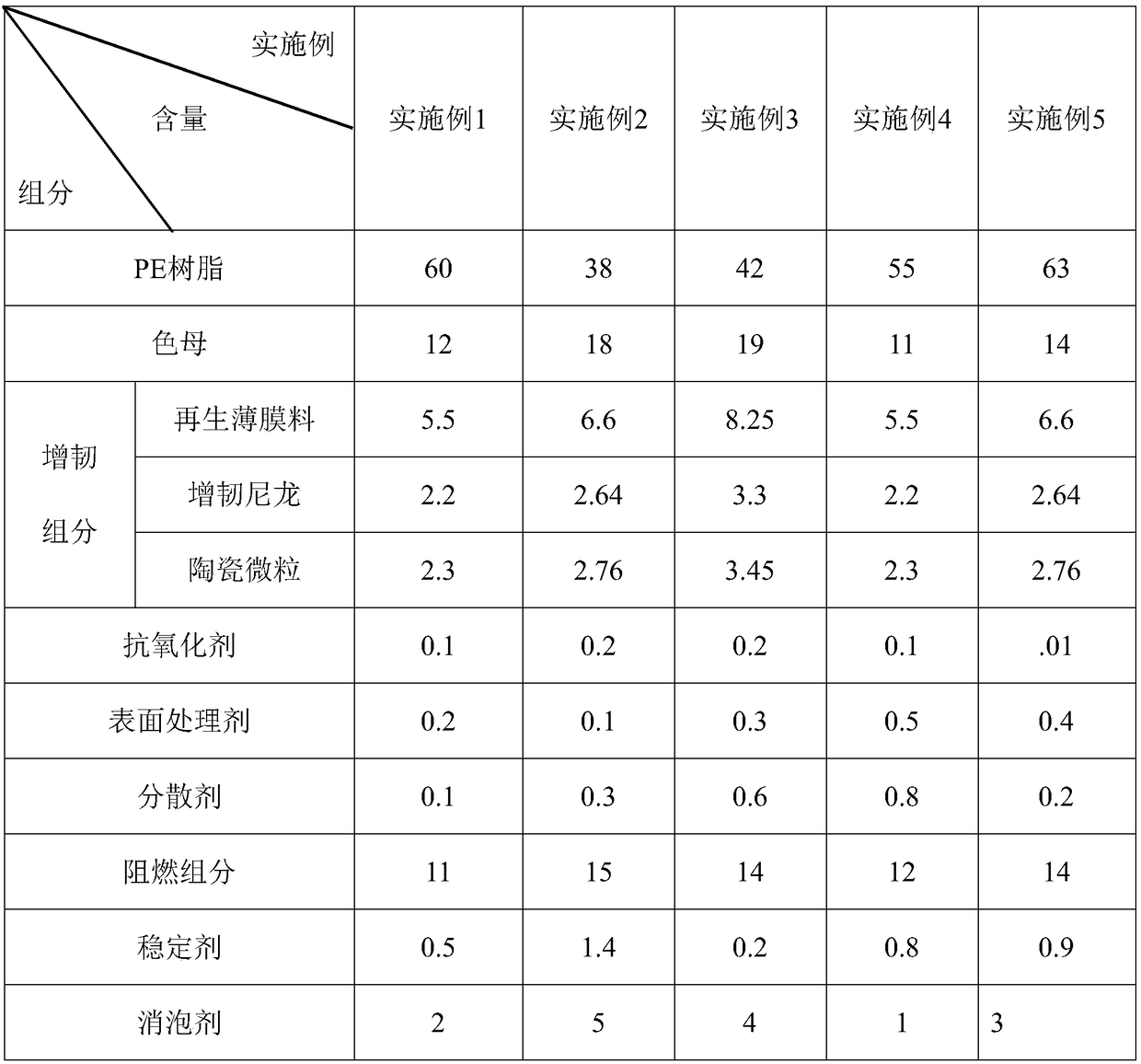

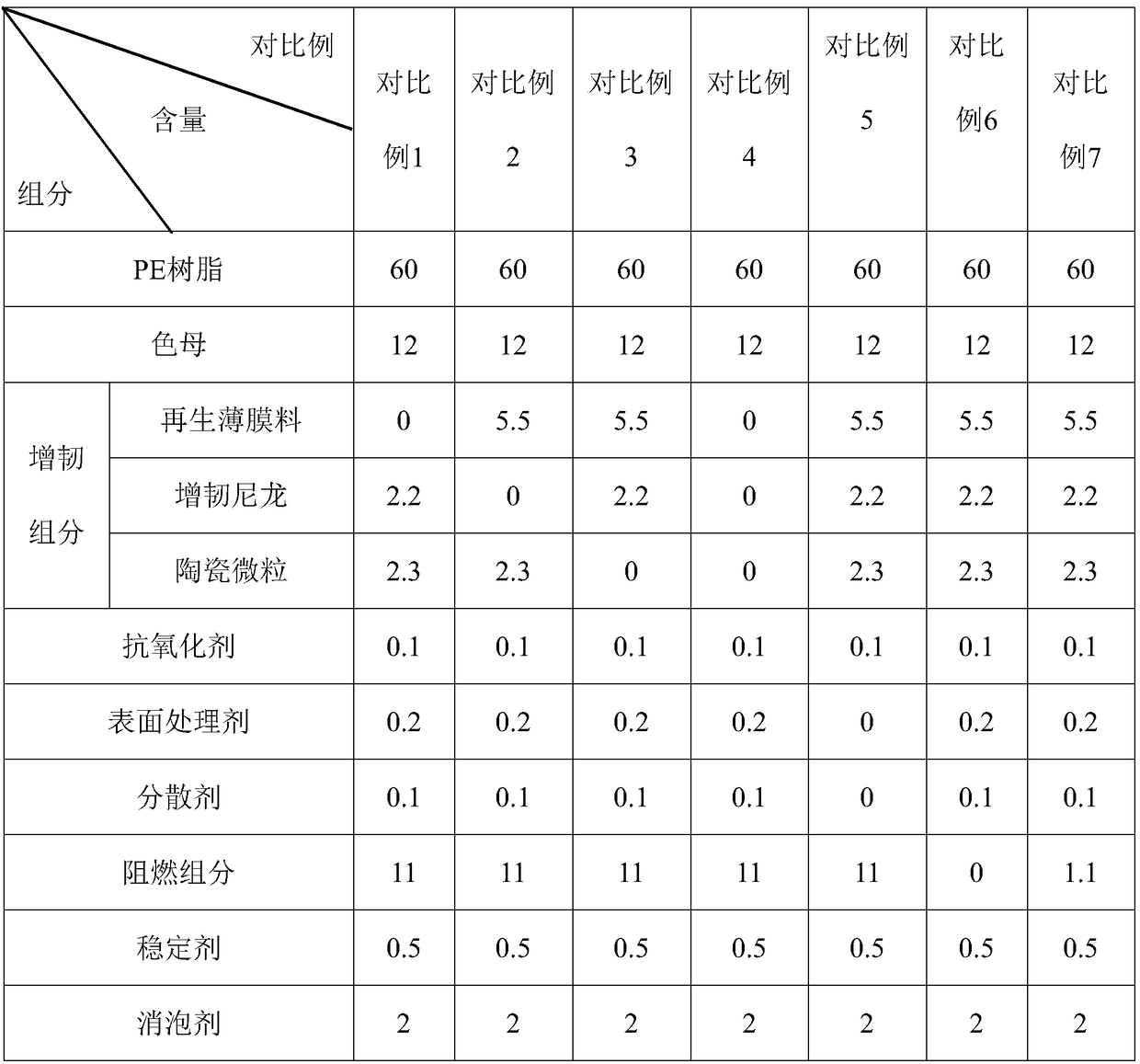

[0028] Embodiment 1-5: A PE pipe, its components and their corresponding contents are shown in Table 1, wherein the antioxidant is antioxidant 1010, the PE resin is high-density PE, and the surface treatment agent is pentaerythritol stearin Acid amine, polyethylene wax as a dispersant, perchloric acid and carbon black with a weight ratio of 1:1 as a stabilizer, and emulsified silicone oil as a defoamer.

[0029] The toughening component is composed of recycled film material, toughened nylon, and ceramic particles. The weight ratio of the three is 55:22:23, and the particle size of the ceramic particles is 10-45 μm. The flame retardant component is composed of activated modified ultrafine calcium carbonate powder and activated modified magnesium hydroxide powder with a weight ratio of 1:1, wherein the activated modified ultrafine calcium carbonate powder includes 95% by weight ultrafine Calcium carbonate, 3% silane coupling agent, 2% aluminum-titanium composite coupling agent, ...

Embodiment 6

[0032] Example 6, a PE pipe, differs from Example 1 in that: the surface treatment agent is a silane coupling agent, and the dispersant is a compound of stearic acid and polyethylene wax.

Embodiment 7

[0033] Example 7, a PE pipe, the difference from Example 1 is that the activated modified ultrafine calcium carbonate powder includes 97% by weight of ultrafine calcium carbonate, 2% silane coupling agent, 1% aluminum-titanium composite coupling joint agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com