High-toughness concrete composition

A concrete composition and high toughness technology, applied in the field of concrete compositions, can solve the problems of low strength of polypropylene fibers, low elastic modulus, no obvious enhancement of flexural and tensile strength, etc., and achieve high tensile strength and flexural strength, The effect of improving integrity and shock resistance, ensuring impermeability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

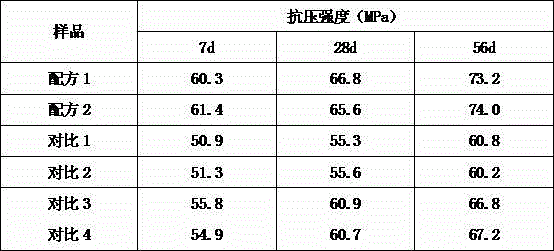

[0022] Embodiment 1: Effect of phosphorus slag powder and fly ash on compressive strength

[0023] Table 1: The formula composition of formula 1-2 and comparative example 1-4

[0024] Components (parts by weight) Recipe 1 Recipe 2 Contrast 1 Contrast 2 Contrast 3 Contrast 4 cement 300 500 300 300 500 500 Phosphorus slag powder 30 50 —— 120 50 30 fly ash 90 150 120 —— 90 120 fine aggregate 1000 1100 1000 1000 1000 1000 Coarse aggregate 600 750 600 600 600 600 Superplasticizer 5 15 5 5 5 5 mixed fiber 10 20 10 10 10 10 Polyvinylpyrrolidone 10 10 10 10 10 10 recycled rubber 15 15 15 15 15 15 Zeolite 5 10 5 5 5 5 water 130 180 130 130 130 130

[0025] experiment method:

[0026] Each sample was prepared according to the formula in Table 1; raw material cement, phosphorus slag powder, fly ash, fine aggregate, coarse aggregate, water reduc...

Embodiment 2

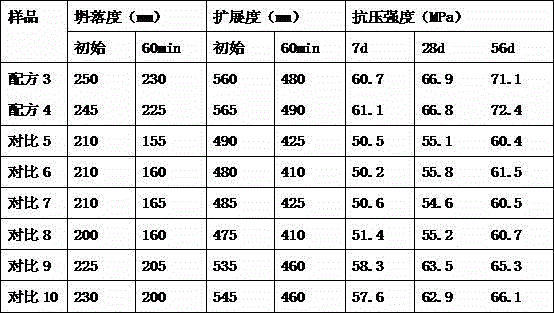

[0032] Example 2: Effects of different water reducing agents on slump and compressive strength

[0033] Test method: each sample was prepared according to the formula in Table 3; the raw materials cement, phosphorus slag powder, fly ash, fine aggregate, coarse aggregate, water reducing agent, mixed fiber, polymer in formula 3-4 and comparison 5-10 Vinylpyrrolidone, reclaimed rubber, zeolite and water are all of the same specification, standard or composition.

[0034] Slump is the oldest and most common method for determining the fluidity of mixtures. The slump test refers to the standard JTG E30-2005. The test of the slump spread value is based on the slump test, and the spread value of the mixture in the horizontal direction is measured at the same time, and then the spread values in the two vertical directions are measured. , take the average value, which is the value of slump spread.

[0035] Experimental results:

[0036] It can be concluded from Table 4 that selecti...

Embodiment 3

[0042] The composition and parts by weight of the high toughness concrete composition of the present invention are as follows:

[0043] Cement 300 parts

[0044] Phosphorus slag powder 30 parts

[0045] 90 parts of fly ash

[0046] Fine aggregate 1000 parts

[0047] Coarse aggregate 600 parts

[0048] 5 parts of water reducer

[0049] 10 parts mixed fiber

[0050] 10 parts polyvinylpyrrolidone

[0051] 15 parts recycled rubber powder

[0052] Zeolite 15 parts

[0053] 130 parts of water;

[0054] Wherein said mixed fiber is carbon fiber, polypropylene fiber, polyester fiber and bagasse pulverized thing, wherein the weight ratio of carbon fiber, polypropylene fiber, polyester fiber and bagasse pulverized thing is 1:2:2: 5.

[0055] The basic mechanical performance test result of embodiment 3 gained concrete is as follows:

[0056] (1) Bending strength

[0057] Specimen size: 400mm×100mm×15mm

[0058] Test method: four-point bending, three-point loading, the test sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com