Basement narrow space outer wall construction structure and method

A construction method and basement technology, applied in building construction, on-site preparation of building components, connection parts of formwork/formwork/work frame, etc., can solve the problems of increased construction difficulty, unpredictable quality risks and safety risks, support Set templates and other issues to achieve good waterproof performance, ensure the quality of exterior wall construction, and achieve low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

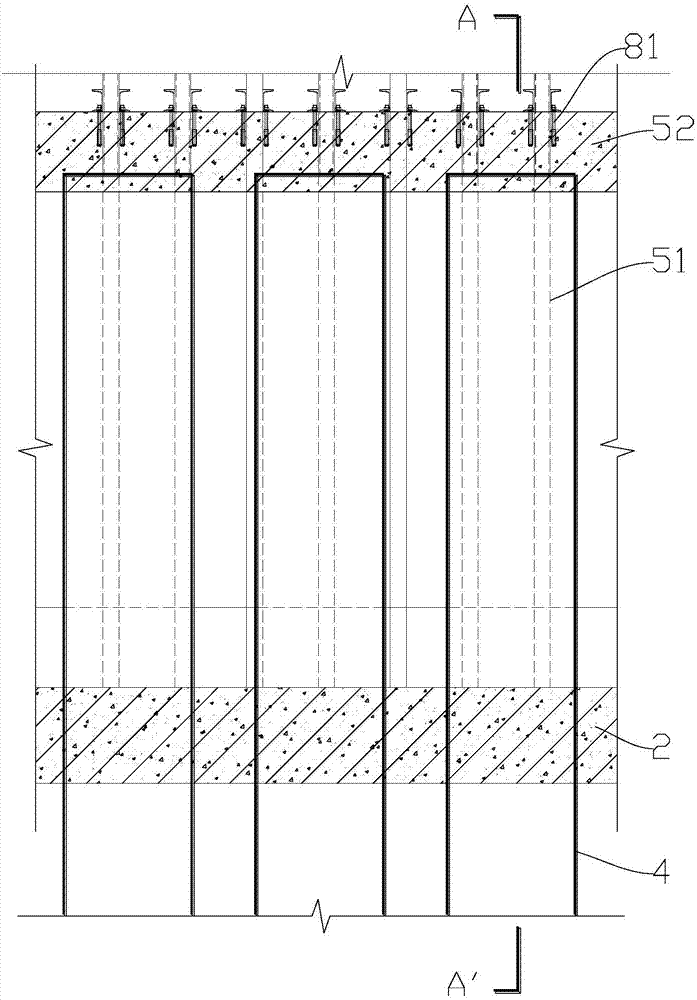

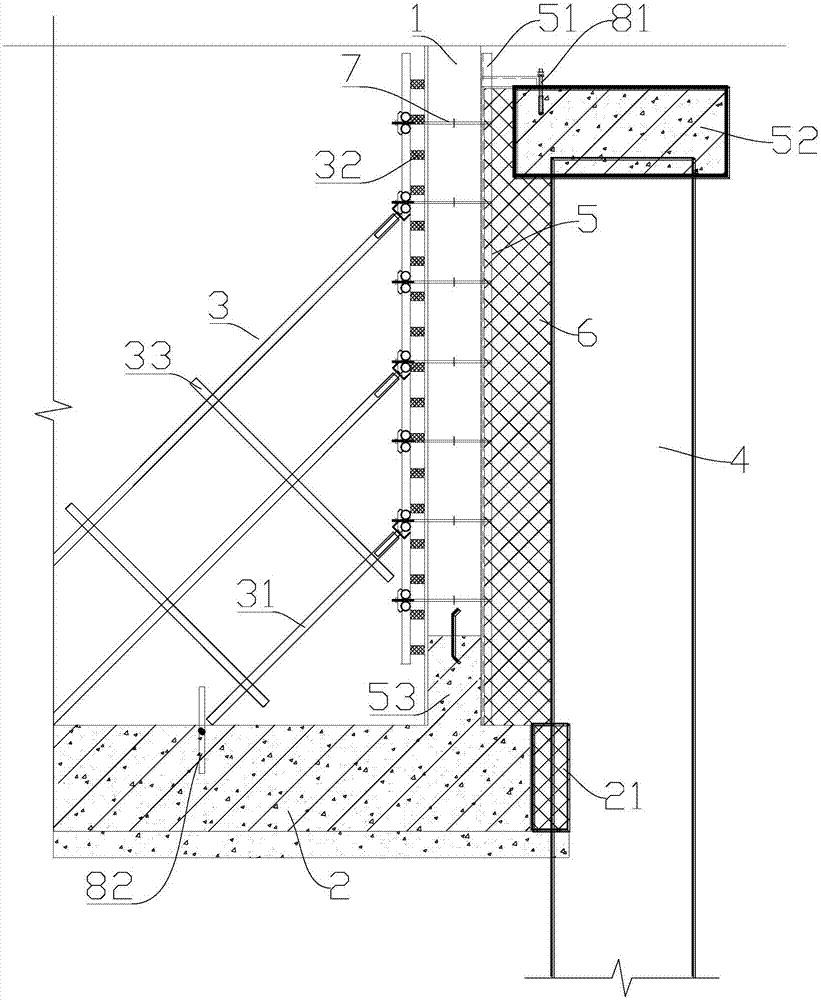

[0034] Embodiment one, as figure 1 and figure 2 As shown, a construction structure of exterior walls in a narrow basement space includes exterior wall reinforcement skeletons, rafts 2, inner support systems 3 and support piles 4, exterior wall reinforcement skeletons are arranged around exterior wall area 1; at the bottom of the outer wall area 1; the inner support system 3 is set on the inner side of the outer wall area 1; the support pile 4 is set on the outer side of the outer wall area 1; The outer support system 5 includes a plurality of channel steels 51, and the plurality of channel steels 51 are vertically arranged between the outer wall area 1 and the support piles 4.

[0035] A plurality of vertical channel steels 51 are preferably equidistantly arranged between the outer wall area 1 and the support piles 4. The equidistant arrangement of the plurality of channel steels 51 can ensure that each channel steel 51 is stressed when pouring the outer wall concrete. Same...

Embodiment 2

[0042] Embodiment 2. A construction method for an exterior wall in a narrow basement space, comprising the following steps:

[0043] Step S1: setting the outer support system 5 on the outer side of the outer wall area 1;

[0044] Step S2: installing the outer wall reinforcement skeleton around the outer wall area 1;

[0045] Step S3: setting the inner support system 3 on the inner side of the outer wall area 1 .

[0046] Preferably, the specific implementation of step S1 is:

[0047]Step S11: set a crown beam 52 on the upper end of the support pile 4, and set a concrete anti-sill 53 corresponding to the outer wall area 1 on the raft 2;

[0048] Step S12: Set a plurality of vertical channel steels 51 between the outer wall area 1 and the support piles 4, and fix the upper ends of the plurality of channel steels 51 on the crown beam 52, and the lower ends of the plurality of channel steels 51 Set on the concrete anti-sill 53;

[0049] Step S13 : setting multiple water-stop s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com