Bio-based nano composite epoxy coating inspired by nacre as well as preparation method and application of bio-based nano composite epoxy coating

A nano-composite, epoxy coating technology, applied in epoxy resin coatings, anti-corrosion coatings, coatings and other directions, can solve problems such as harming the environment, not conforming to the green environmental protection concept of metal corrosion protection coatings, etc., to ensure impermeability, The effect of ensuring the availability of circular economy and excellent self-healing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention also provides the aforementioned preparation method of a kind of bio-based nano-composite epoxy coating inspired by nacre, comprising:

[0042] (1) Synthesis of GO-UPy, in some embodiments, 2-amino-4-hydroxyl-6-methylpyrimidine and hexamethylene diisocyanate (HDI) were added to a round-bottomed flask, and under nitrogen atmosphere React at high temperature for 12 hours. After cooling to room temperature, use n-hexane to wash away the unreacted HDI; then, dry the product in a vacuum drying oven overnight to obtain a white powder (UPy-NCO); then take an appropriate amount of graphene oxide (GO) and UPy-NCO were dispersed in N,N-dimethylformamide (DMF) solution, and an appropriate amount of dibutyltin dilaurate catalyst was slowly added; heated to 40°C under nitrogen atmosphere, after 24 hours of reaction, The mixture was then collected by vacuum filtration, and finally the product was washed with DMF and ethanol to obtain GO-UPy;

[0043] (2) Synthe...

Embodiment

[0049] In this embodiment, the preparation method of the bio-based nanocomposite epoxy coating inspired by nacre, the specific implementation includes the following steps:

[0050] (1) Synthesis of GO-UPy

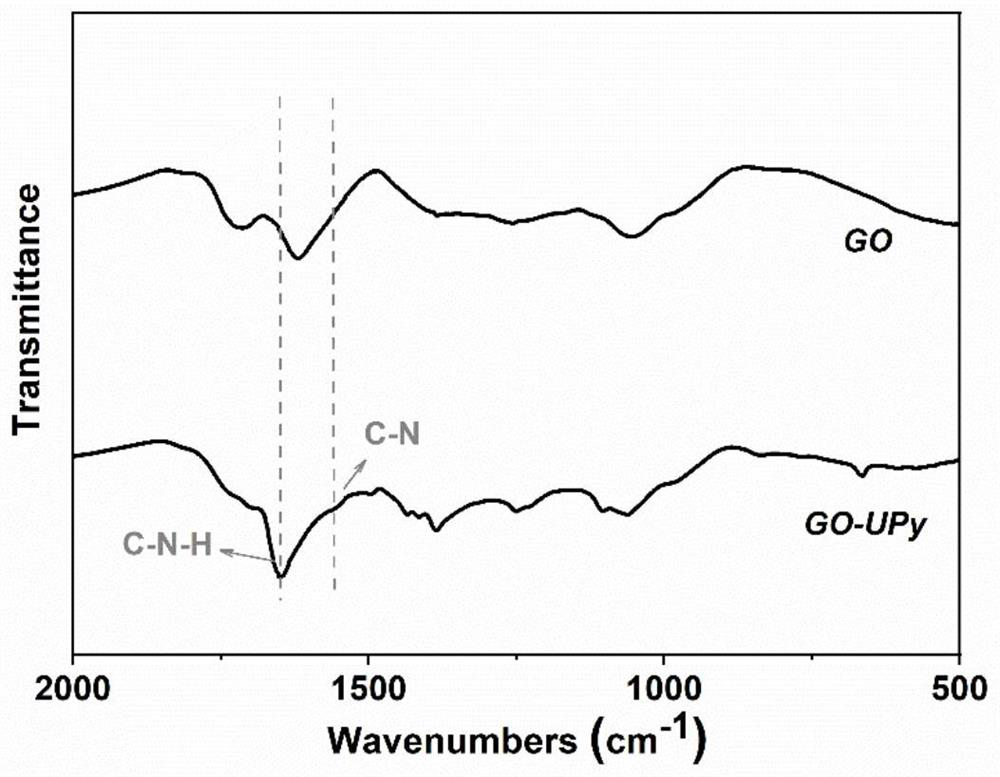

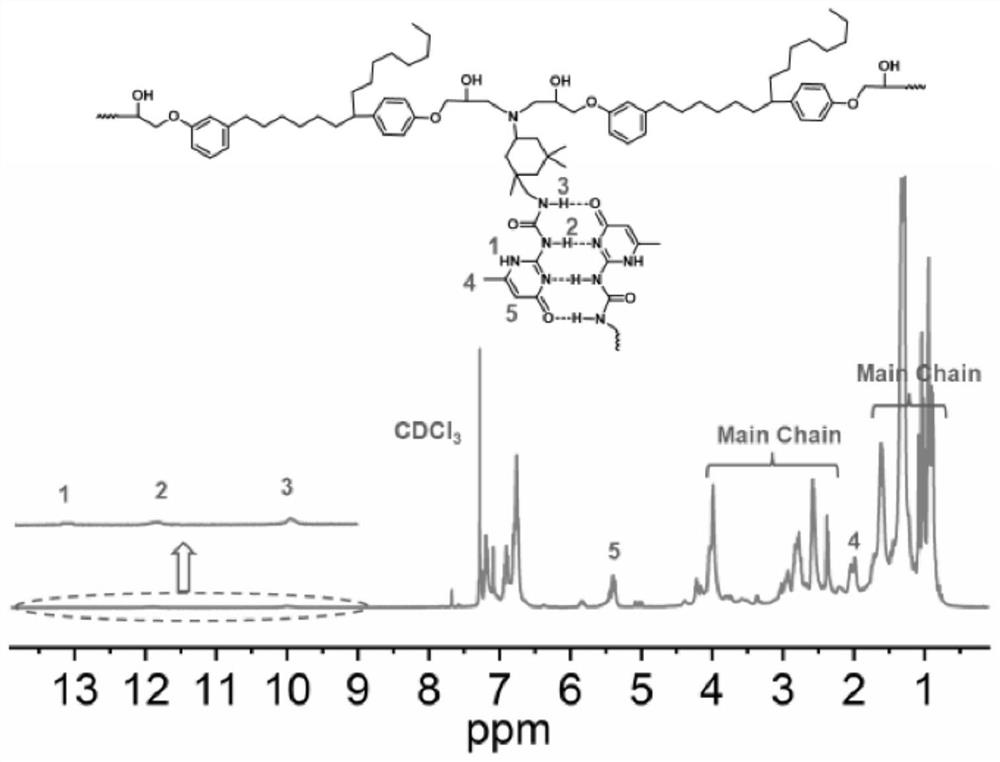

[0051] Add 2-amino-4-hydroxy-6-methylpyrimidine (3g, 23mmol) and hexamethylene diisocyanate (HDI) (24.2g, 143mmol) into a round bottom flask, and react at 110°C under a nitrogen atmosphere for 12 Hours, after being cooled to room temperature, use n-hexane to wash away the unreacted HDI; Subsequently, the product was dried overnight in a vacuum drying oven to obtain a white powder (UPy-NCO) (6.3g, yield 93.4%); then Take 0.5g of graphene oxide (GO) and 0.1g of UPy-NCO and disperse in N,N-dimethylformamide (DMF, 100mL) solution, and slowly add dibutyltin dilaurate (0.2mL); Heated to 40°C under atmosphere, reacted for 24 hours, then collected the mixture by vacuum filtration, and finally washed the product with DMF and ethanol to obtain GO-UPy. The infrared spectra before and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

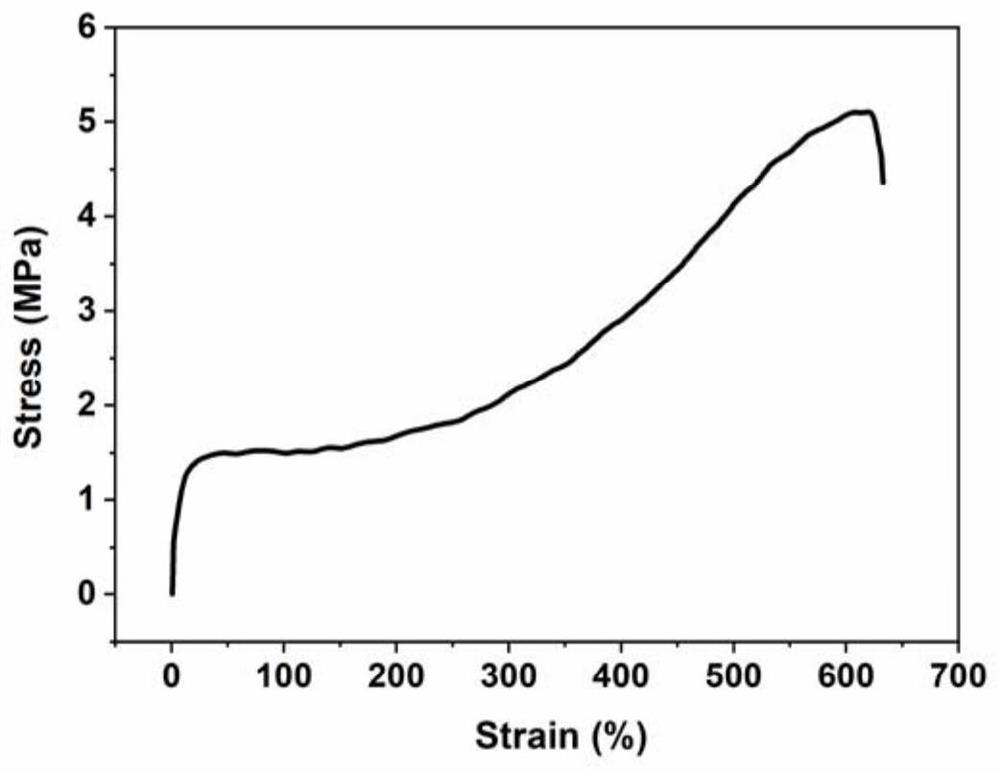

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com