Separation system for removing biotite from artificial sand

A sorting system, artificial sand technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of low guarantee rate, unfavorable project development, increased transportation costs, etc., to achieve convenient operation and simplified sorting system structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

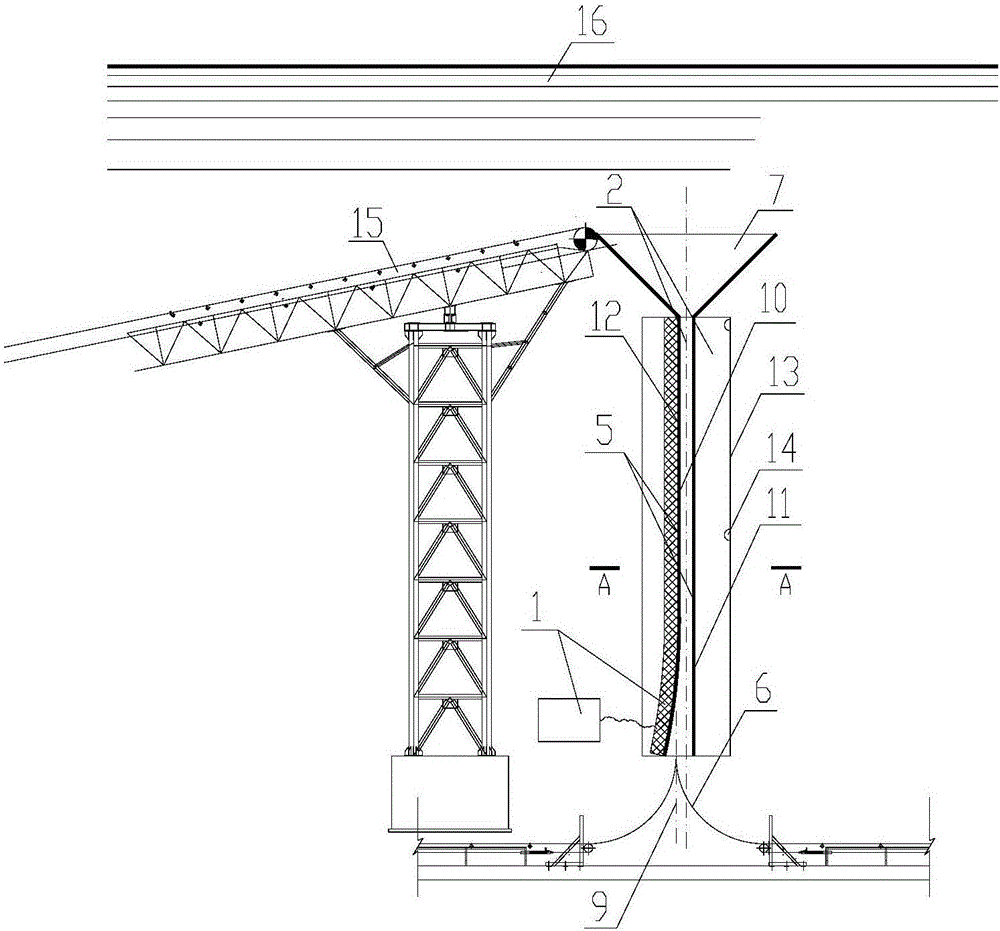

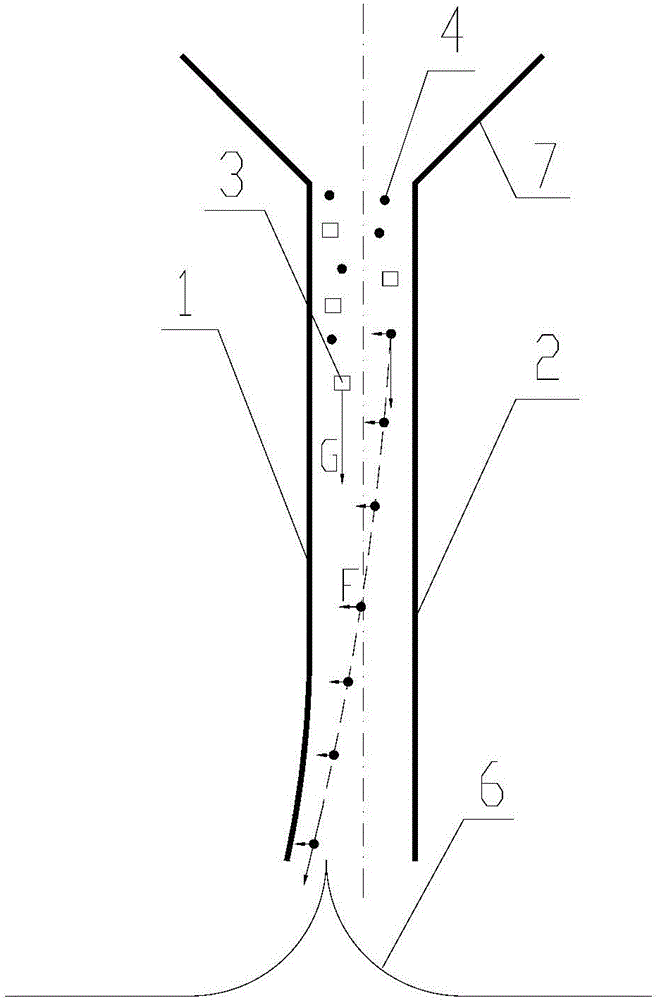

[0057] In the traditional artificial sand production process, the sorting system provided by this application is added before the finished sand enters the stockyard, as shown in the attached figure 1 shown. The specific implementation process is as follows:

[0058] Production preparation stage:

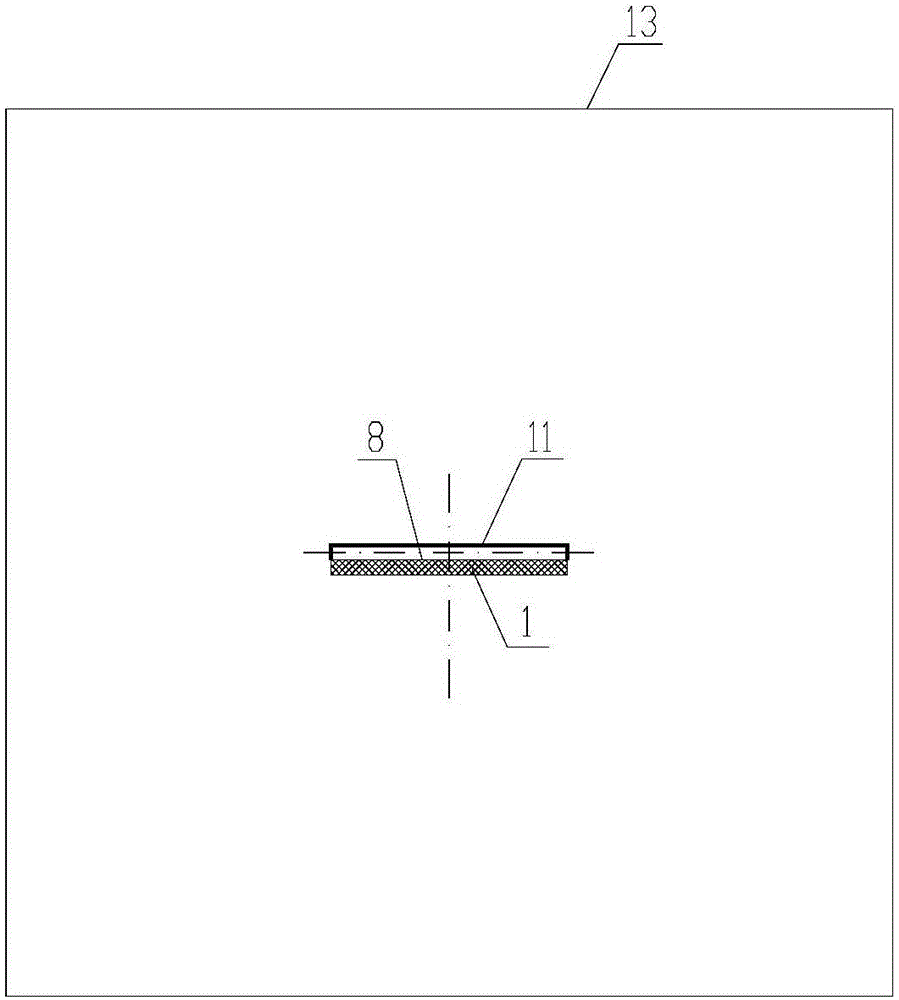

[0059] Laboratory physical and chemical tests are carried out according to the raw materials mined in the engineering stockyard, and the obtained biotite content is usually free, biotite chemical components such as FeO, Fe 2 o 3 etc., and determine the density, specific magnetic susceptibility, specific gravity, etc. of mica. So as to carry out technical and economic comparison and selection, and then determine the characteristic indicators of this sorting system: magnetic field strength is the magnetic field force, magnetic pole width, falling height is time, theoretical offset, and channel width.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com