Construction method of super-deep shield shaft in water-rich weak stratum

A technology for weak strata and construction methods, applied in vertical shaft equipment, earthwork drilling, wellbore lining, etc., can solve problems such as inapplicability, reduced construction efficiency, and major safety issues, and achieve improved construction efficiency, good stability, The effect of improving construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0060] A construction method for an ultra-deep shield shaft in a water-rich and weak stratum, comprising the following steps:

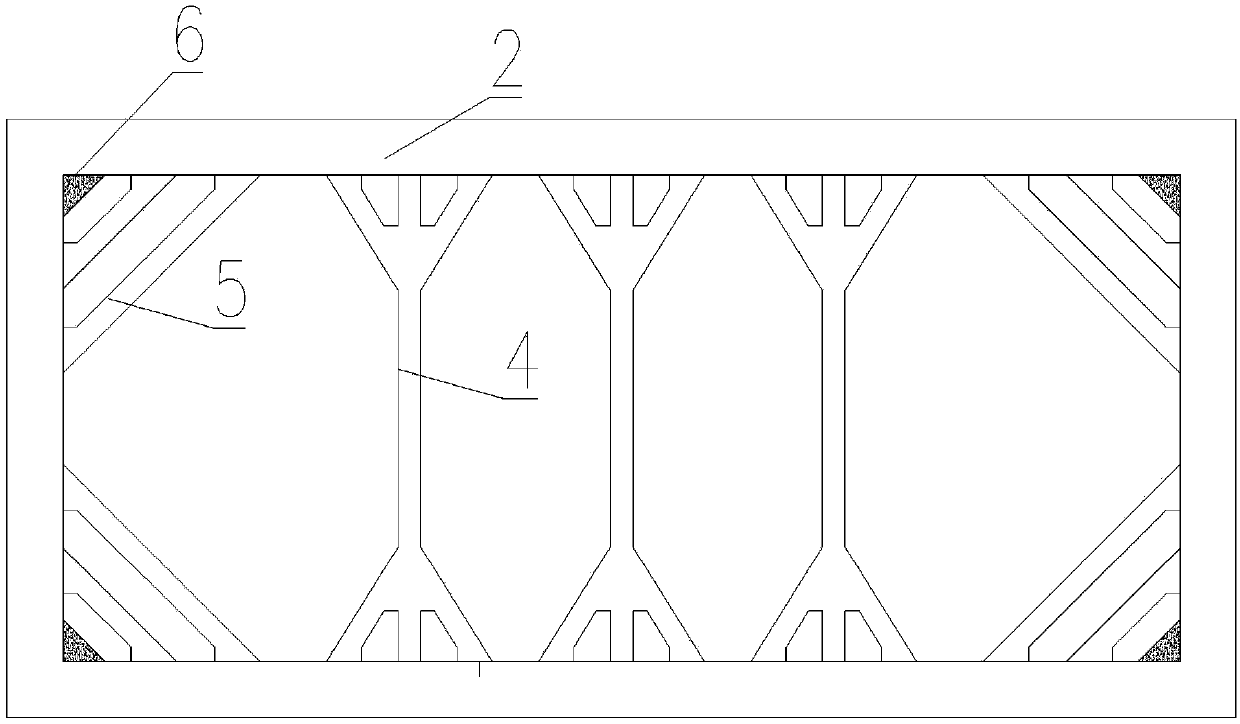

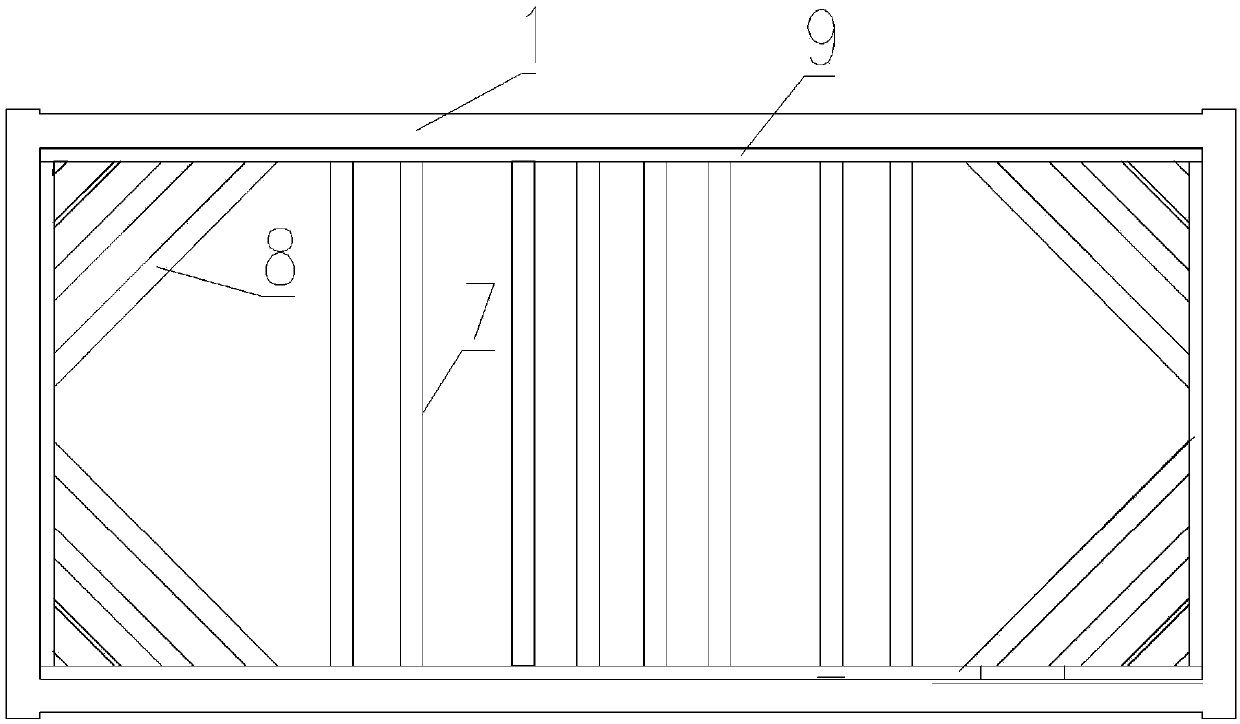

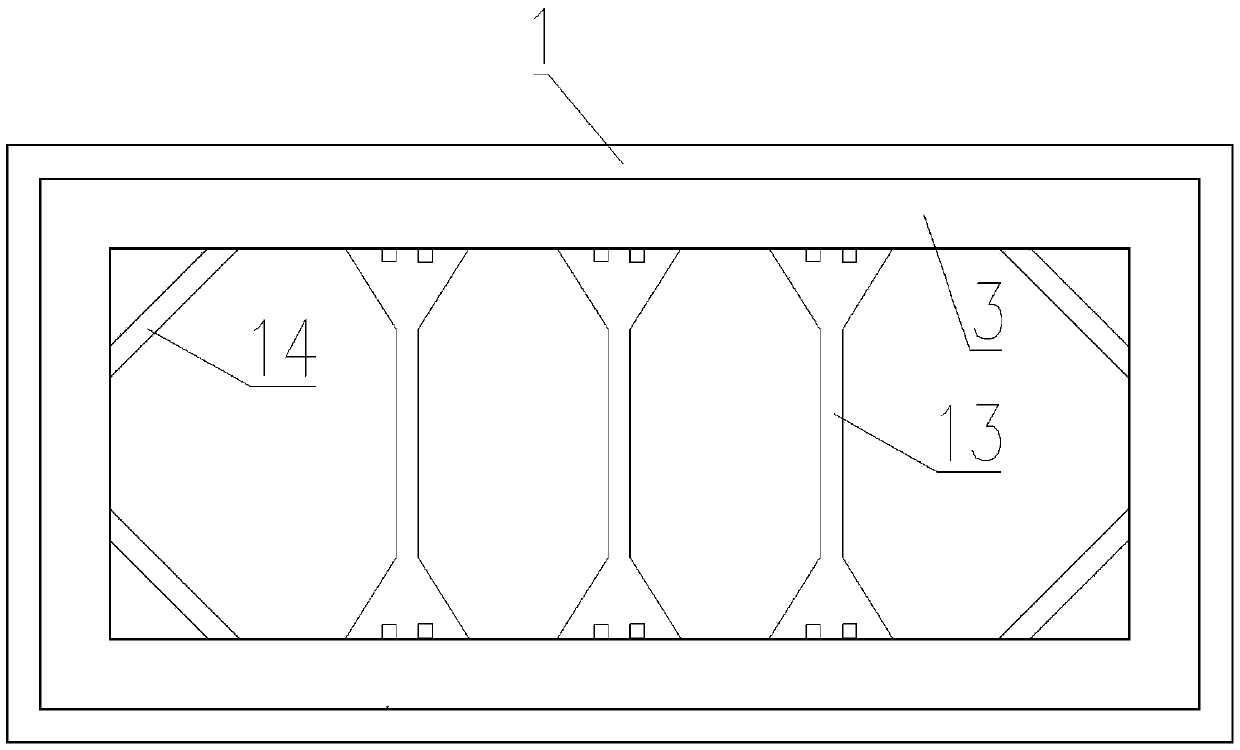

[0061] Step 1: Construct the enclosure structure of the underground diaphragm wall 1 of the shaft;

[0062] Step 1.1: First construct the double-span I-beam joint of the underground diaphragm wall 1;

[0063] Step 1.2: Divide the trough into troughs, check the verticality of the trough wall, hoist the reinforcement cage, and finally pour the underwater concrete;

[0064] Step 1.3: Install fiberglass reinforcement cages in the scope of the starting portal or receiving portal of the shield machine, and pour underwater concrete;

[0065] Step 1.4: complete the construction of all underground diaphragm wall 1 structures in turn;

[0066] Step 2: Stratum reinforcement at the end of the shield shaft;

[0067] Step 3: Divide the upper 20 meters of the shaft into four layers, carry out excavation layer by layer, and erect the steel support system;

[0068...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com