Mass conductive concrete based on ironmaking dedusting ash

A conductive concrete and large-volume technology, which is applied in the field of building materials, can solve the problems of the citizens’ normal life, the preparation of conductive concrete, and the rainy and snowy weather, etc., and achieve the effects of excellent impermeability, wide range of uses, and low electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

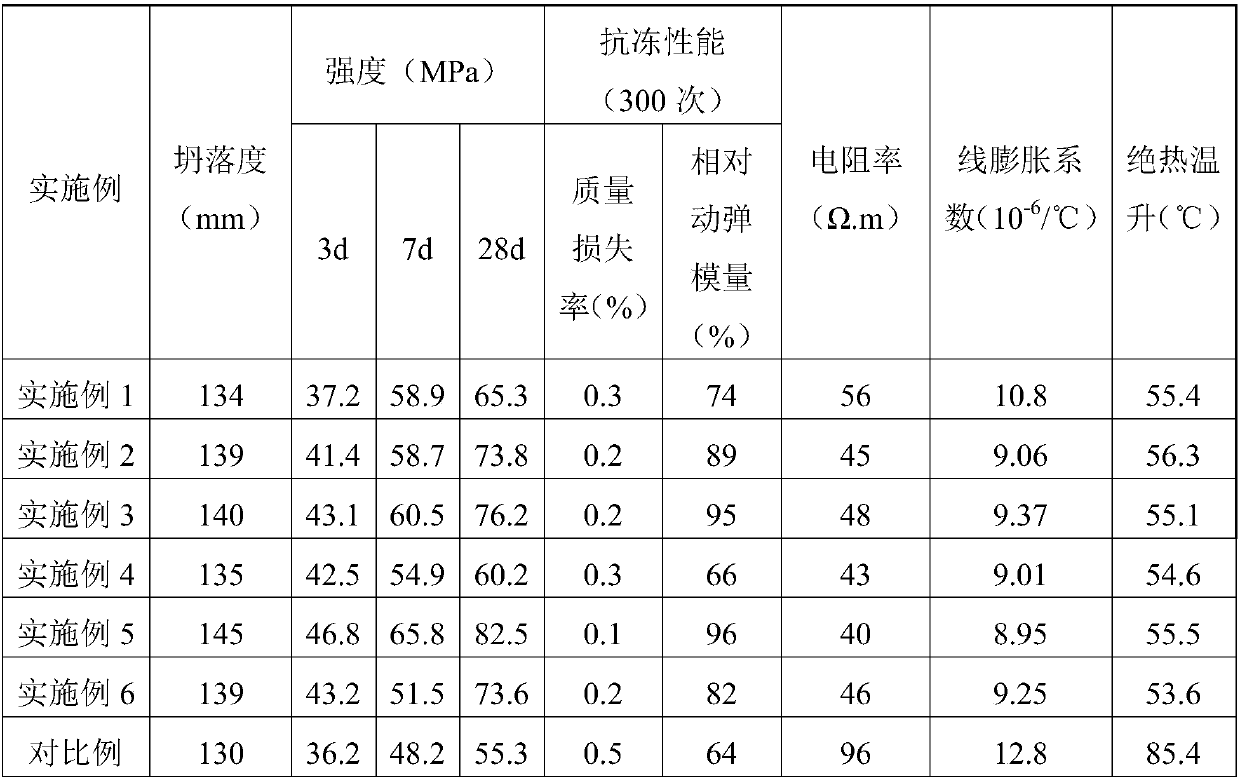

Examples

Embodiment 1

[0025] According to the following parts by weight, the raw materials are weighed and proportioned to obtain a large-volume conductive concrete based on ironmaking dust removal ash:

[0026] 100 parts of 42.5 grade ordinary Portland cement, 1 part of fly ash, 1 part of blast furnace slag powder, 1 part of ironmaking dust removal ash, 120 parts of yellow sand, 10 parts of blast furnace slag iron particles, 4 parts of water reducing agent, 10 parts of copper fiber , 5 parts of polyphenylene vinylene, 8 parts of polyvinylpyrrolidone, and 33 parts of water; among them, the fly ash is collected from the flue gas of coal combustion in thermal power generation, and the blast furnace slag powder is made by grinding the slag produced by blast furnace ironmaking; Iron dust is calculated by mass percentage, including: carbon content is 5% to 65%, iron content is 10% to 60%, and the balance is impurities; blast furnace slag iron particles are obtained by blast furnace slag iron separation, ...

Embodiment 2

[0028] According to the following parts by weight, the raw materials are weighed and proportioned to obtain a large-volume conductive concrete based on ironmaking dust removal ash:

[0029] 100 parts of 42.5 grade ordinary Portland cement, 50 parts of fly ash, 50 parts of blast furnace slag powder, 10 parts of ironmaking dust, 120 parts of yellow sand, 20 parts of blast furnace slag iron particles, 180 parts of 5-25mm crushed stone, water reducing 6 parts of copper fiber, 15 parts of copper fiber, 10 parts of polyphenylene vinylene, 15 parts of polyvinylpyrrolidone, and 72 parts of water; among them, fly ash is collected from the flue gas of coal combustion in thermal power generation, and blast furnace slag powder is produced by blast furnace ironmaking The slag is finely ground; ironmaking dust is calculated by mass percentage, including: carbon content is 5% to 65%, iron content is 10% to 60%, and the balance is impurities; blast furnace slag iron particles pass through the ...

Embodiment 3

[0031] According to the following parts by weight, the raw materials are weighed and proportioned to obtain a large-volume conductive concrete based on ironmaking dust removal ash:

[0032] 100 parts of 42.5 grade ordinary Portland cement, 100 parts of fly ash, 80 parts of blast furnace slag powder, 25 parts of ironmaking dust, 240 parts of yellow sand, 20 parts of blast furnace slag iron particles, 360 parts of 5-25mm gravel, water reduction 10 parts of chemical agent, 25 parts of copper fiber, 15 parts of polyphenylene vinylene, 15 parts of polyvinylpyrrolidone, and 100 parts of water; among them, the fly ash is collected from the flue gas of coal combustion in thermal power generation, and the blast furnace slag powder is produced by blast furnace ironmaking The slag is finely ground; ironmaking dust is calculated by mass percentage, including: carbon content is 5% to 65%, iron content is 10% to 60%, and the balance is impurities; blast furnace slag iron particles pass throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com