Optimized mounting structure for dome type ceiling and mounting method

An installation structure and dome-shaped technology, which is applied to the ceiling, building components, building structures, etc., can solve the problems of labor, material waste, and the inability to ensure the uniformity of the shape and installation position, so as to reduce the difficulty of work, improve safety, reduce The effect of material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

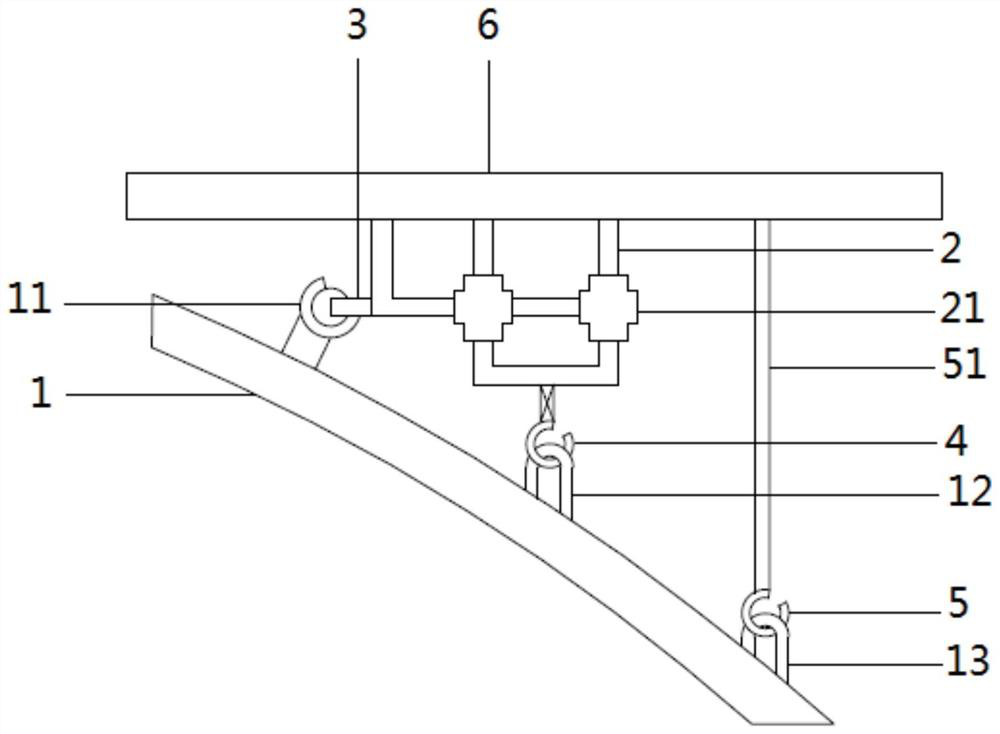

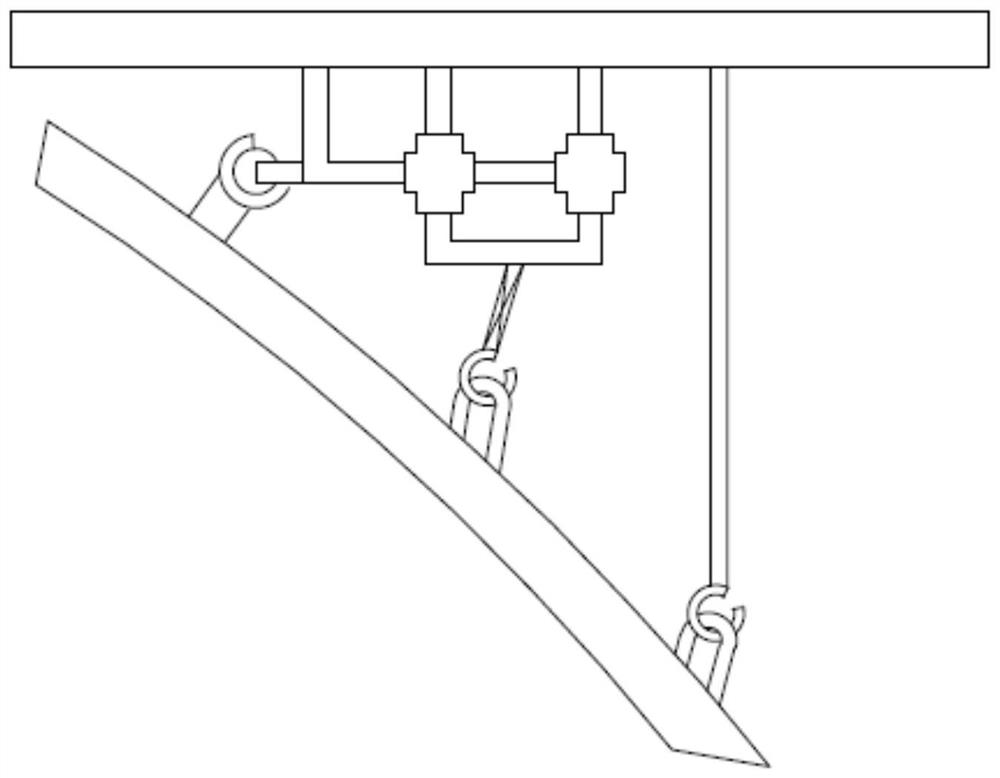

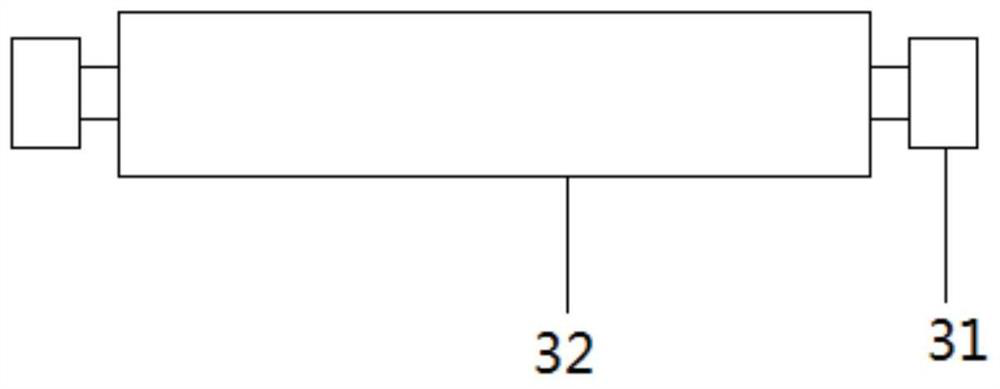

[0029] see Figure 1 to Figure 4 , this embodiment provides an optimized installation structure for a dome-shaped ceiling. Firstly, a curved veneer 1, a conversion layer 2 and a connecting mechanism are provided. The conversion layer 2 is fixedly installed on the ceiling 6, and the curved veneer 1 is installed on the conversion On layer 2, the connecting mechanism includes a first connecting piece 3, a second connecting piece 4 and a third connecting piece 5, the first connecting piece 3 and the second connecting piece 4 are installed on the conversion layer 2, and the third connecting piece 5 is installed on On the ceiling 6, a first installation part, a second installation part and a third installation part are arranged on the curved veneer 1, the first installation part is rotatably connected to the first connector 3, and the second installation part is elastically connected to the second connection 4 , the third mounting part is fixedly connected to the third connecting pi...

Embodiment 2

[0036] see Figure 1 to Figure 4, the figure shows an optimized installation structure of a dome ceiling provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: Embodiment 1 The second connecting piece is elastically connected to the conversion layer through springs, and only one second connecting piece is provided between the curved veneer and the conversion layer. The function of the second connecting piece is explained in more detail here. The first connector and the third connector play a decisive role in fixing the curved veneer above, but considering the heavy weight of some curved veneer, only the first connector and the third connector are used to fix the arc. There is a risk of falling the shaped veneer, so a second connecting piece is added to bear part of the weight of the arc-shaped veneer, and the reason for adding the spring is to enable th...

Embodiment 3

[0038] see Figure 1 to Figure 4 , the figure shows an optimized installation structure of a dome ceiling provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: Embodiment 1 The third connecting piece is hoisted on the ceiling by an aluminum alloy chain. The length of the aluminum alloy chain needs to be adjusted on site. The specific adjustment method is as follows: First, fix one end of the aluminum alloy chain to the second ring, Install the third ring at the position, and then wrap the other end of the aluminum alloy chain around the third ring. The more the number of winding turns, the shorter the distance between the third ring and the second ring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com