A friction welding machine capable of rolling and leveling workpieces

A friction welding and workpiece technology, applied in the field of friction welding, can solve the problems of high leveling cost, many operation steps, and low applicability, and achieve the effects of reducing production costs, convenient process, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

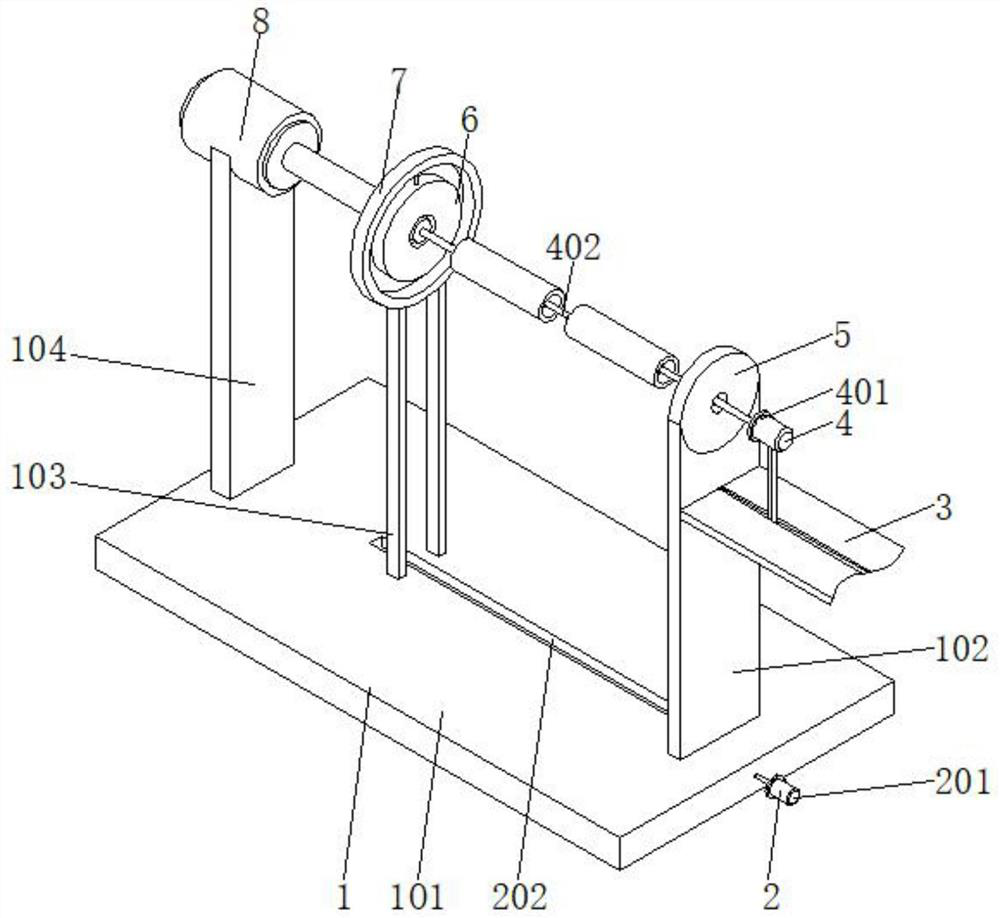

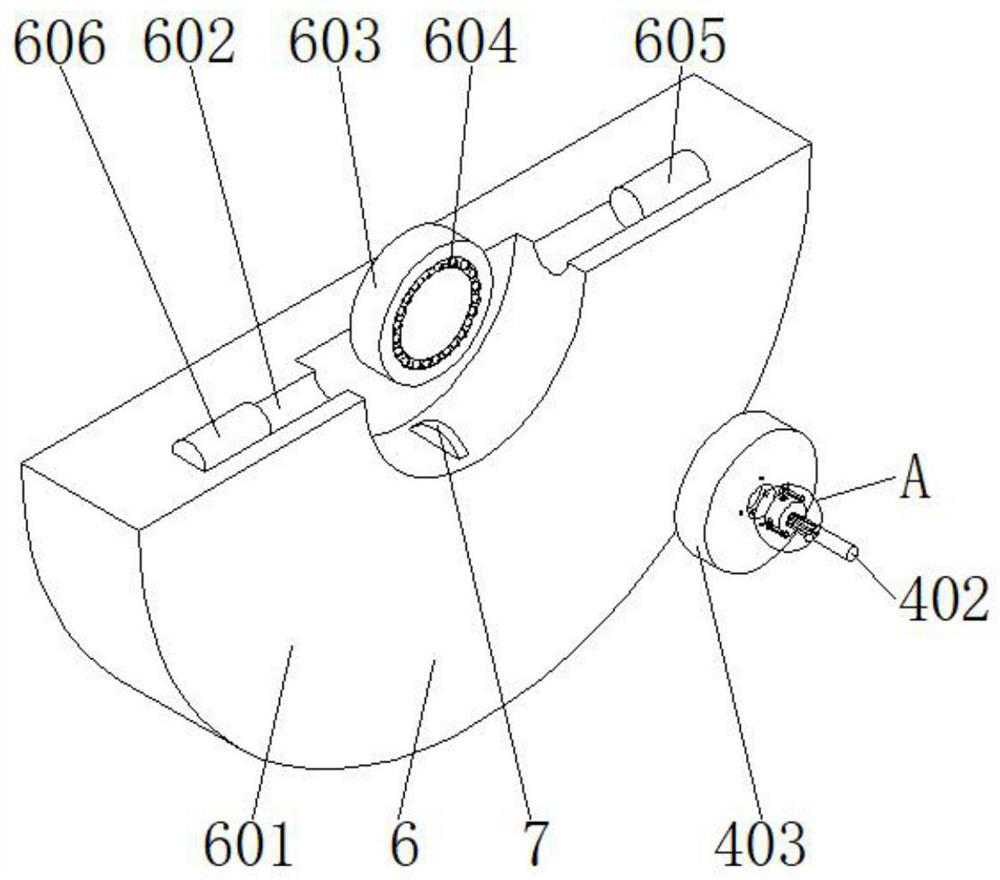

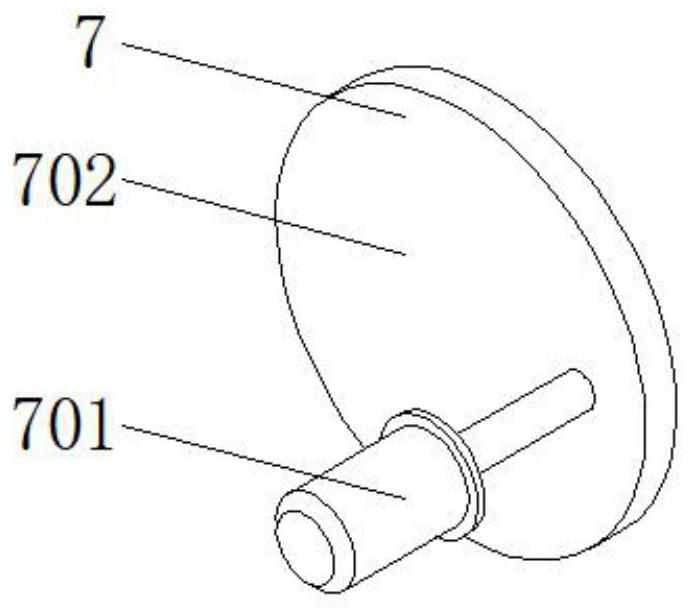

[0045] The present invention provides a friction welding machine capable of rolling and leveling workpieces. Please refer to Figure 1-Figure 11 , including the mounting frame mechanism 1, the mounting frame mechanism 1 includes a base 101, the top of the base 101 is fixed with a No. The top of the 101 is located on the side of the second mounting frame 103, and the third mounting frame 104 is fixed. The top of the third mounting frame 104 is installed with the driving motor 8, and the output end of the driving motor 8 is connected with the second clamping mechanism 6. The second installation The top of the frame 103 is located on the outer wall of the No. 2 clamping mechanism 6 connected with the eccentric mechanism 7, the top of the No. 1 mounting frame 102 is installed with a No. A grinding mechanism 4 is arranged above the 3, and a thrust mechanism 2 is arranged inside the mounting frame mechanism 1;

[0046] Among them, the No. 2 clamping mechanism 6 includes a rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com