External gas removing type heat-storage incinerator

An incinerator and heat storage technology, applied in incinerators, lighting and heating equipment, combustion methods, etc., can solve the problems of pollution switching peak, pollution practical occasions, inconvenience, etc., and achieve the effect of improving ambient air quality and preventing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] Other characteristics and specific embodiments of the present invention can be further understood in the following detailed description with accompanying drawings.

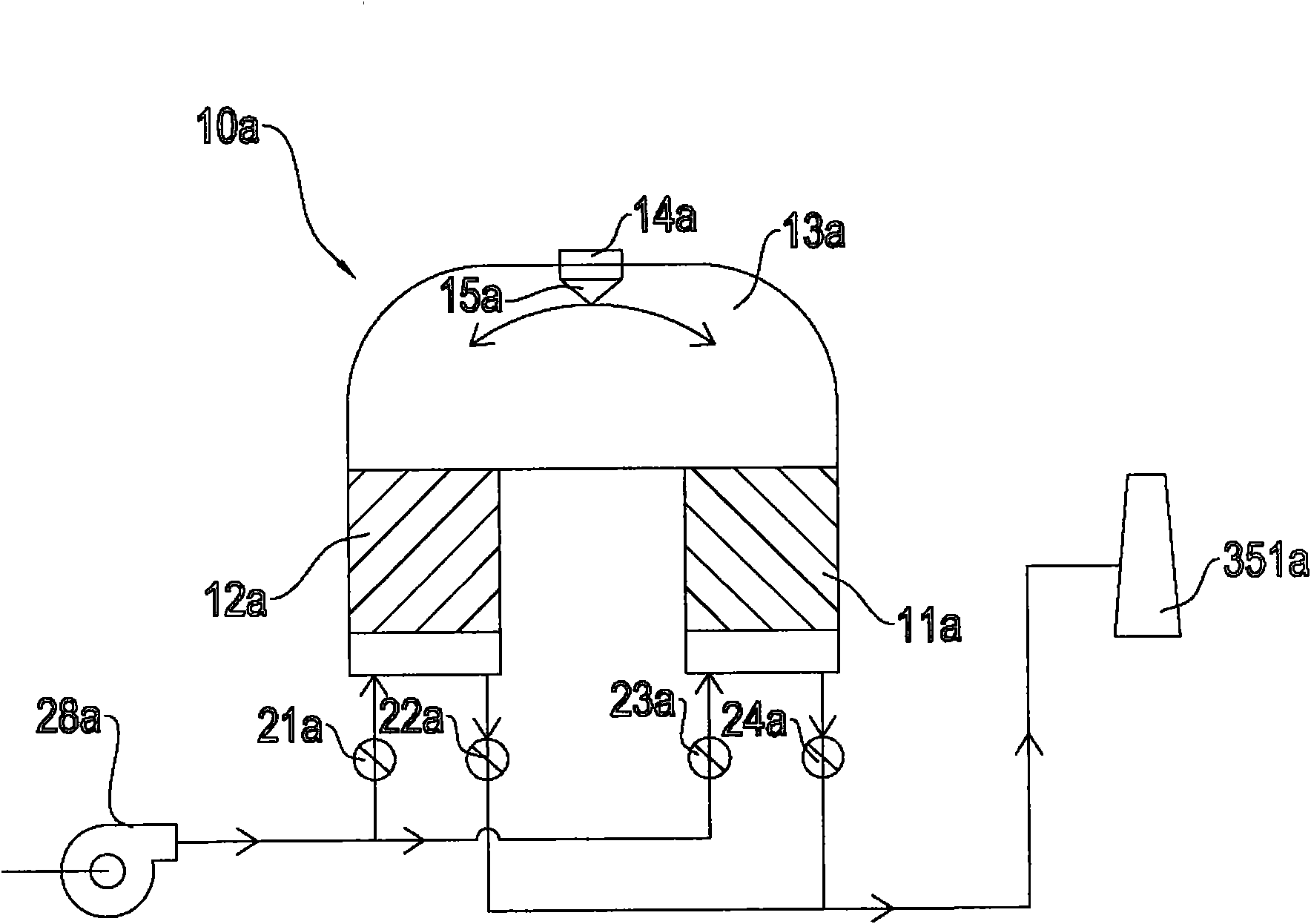

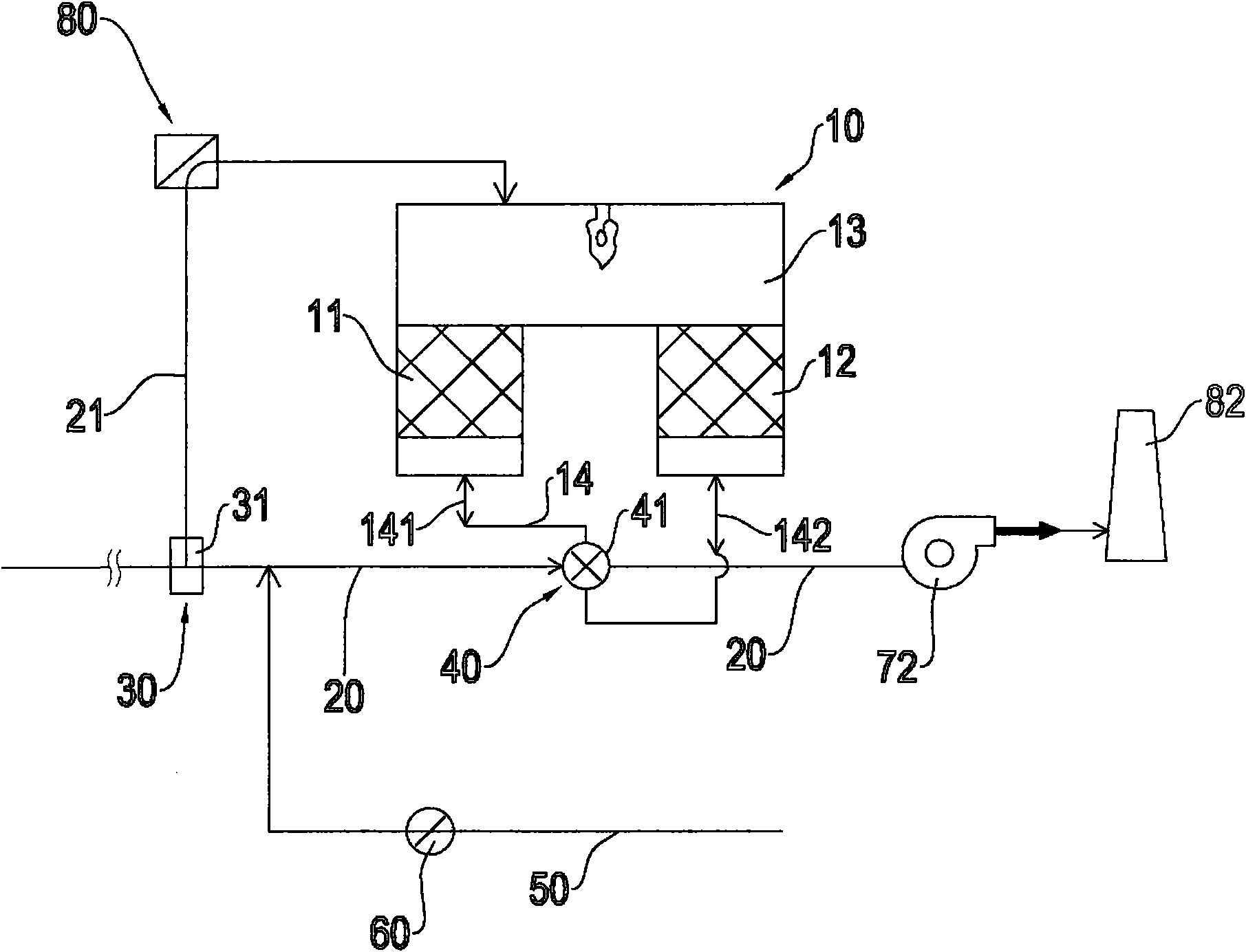

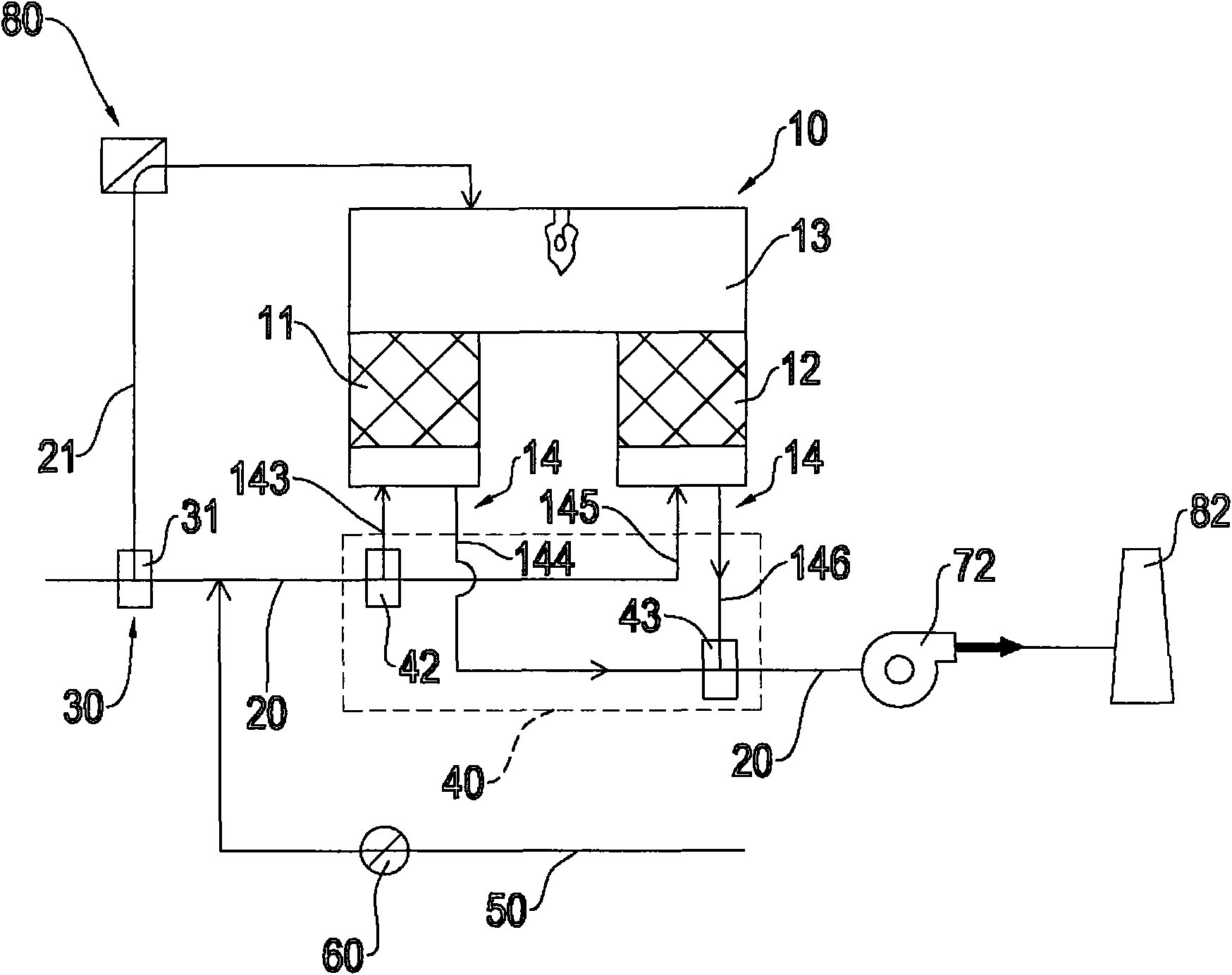

[0082] Please refer to figure 2 As shown, it is a schematic structural view of the external gas removal type regenerative incinerator of the present invention, which includes a regenerative incinerator 10, a main exhaust gas pipeline 20, a windmill 72, an exhaust gas inlet valve group 30, and a leading control valve group 40. An external air supply pipeline 50 and an external air control valve 60; the regenerative incinerator 10 is provided with a first heat storage bed 11, a second heat storage bed 12 and a combustion chamber 13, the combustion chamber 13 The space communicated with the top of the first heat storage bed 11 and the second heat storage bed 12, and the first heat storage bed 11 and the second heat storage bed 12 are respectively provided with at least one ventilation pipeline 14 (the first v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com