A biomass waste pyrolysis furnace system

A cracking furnace and biomass technology, applied in the petroleum industry, the manufacture of combustible gas, fixed bed gasification, etc., can solve the problems that it is difficult to meet the needs of actual production, the possibility of realization is not high, and the operability is poor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

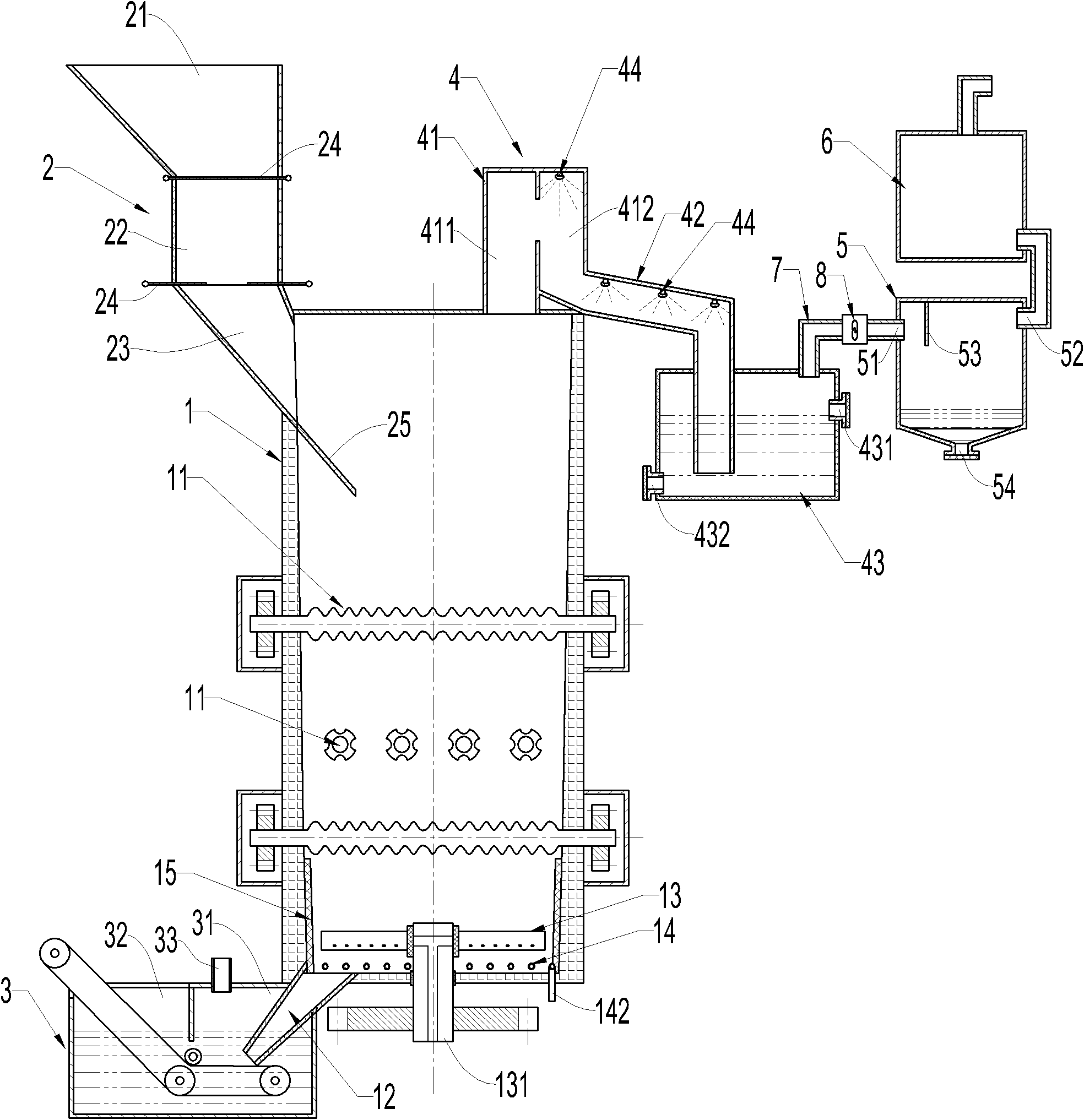

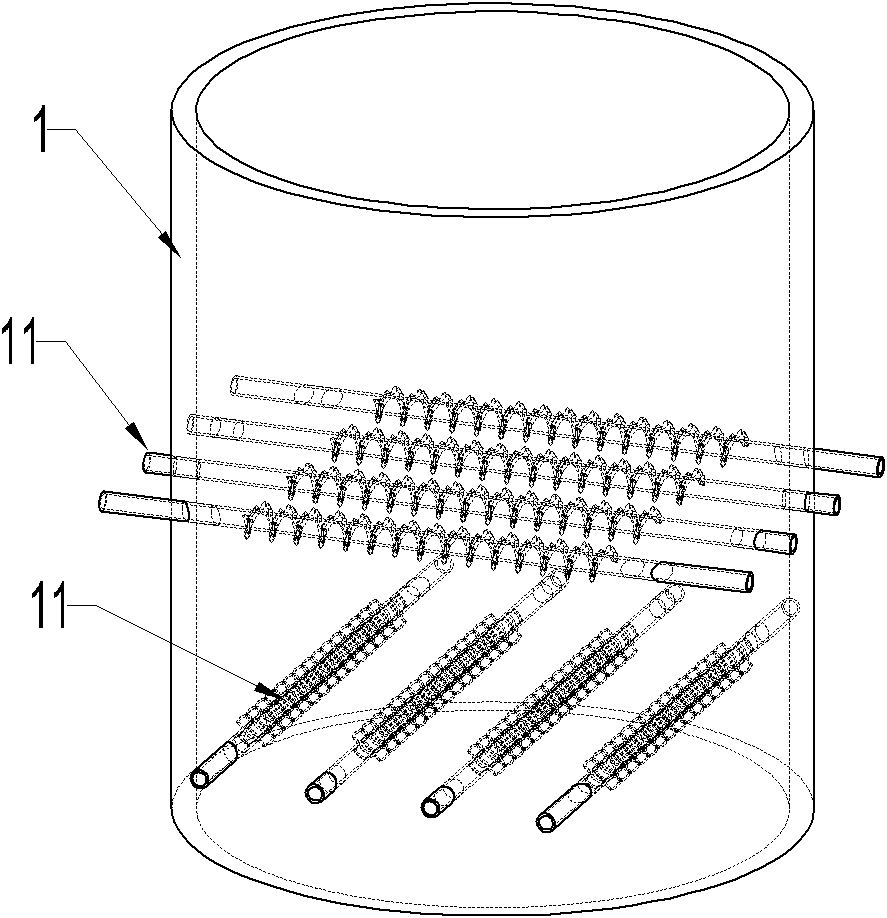

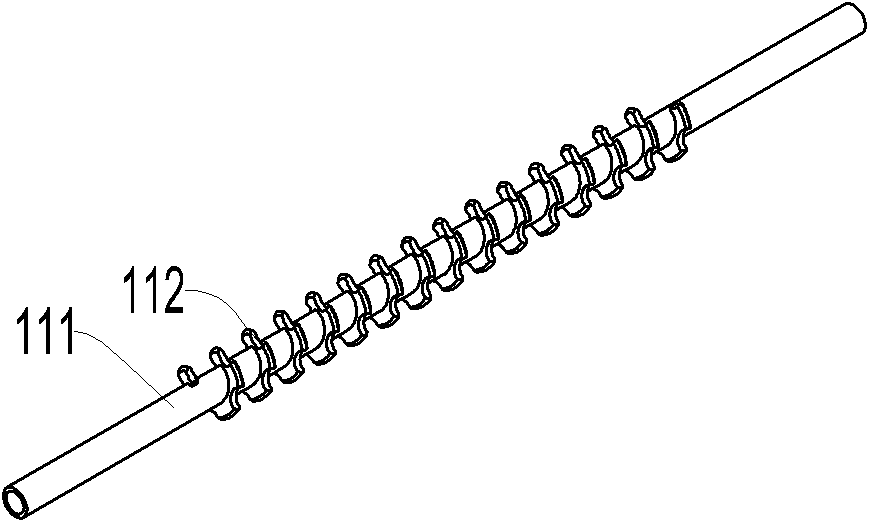

[0047] refer to figure 1 , biomass waste pyrolysis furnace system, including a furnace body 1, a feeding mechanism 2, a slag receiving container 3, a gas scrubber 4, an oil-gas separation tower 5 and a gas collection tower 6; the upper part of the furnace body 1 is provided with a feeding mechanism 2, the The feeding mechanism 2 includes a hopper 21, a hopper 22 and a discharge port 23, and the upper and lower ends of the hopper 22 are respectively provided with movable gates 24; the movable gates 24 are divided into left and right halves or fan-shaped The two halves of the split structure, and the movable gate 24 is driven by a motor or hydraulic pressure, and the movable gate 24 at the upper and lower ends is opened asynchronously, that is, the two are opened and closed alternately. In addition to relatively quantitative feeding, it can especially It guarantees that the movable gate 24 at the lower end is closed in place. The feed opening 23 is extended into the furnace bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com