Linear compressor and oil lubricating method thereof

A linear compressor and oil supply technology, which is applied in mechanical equipment, machines/engines, liquid displacement machines, etc., can solve the problems of easy clogging of micropores, increase of production cost, difficulty in ensuring reliability, etc., and prevent wear and tear , the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

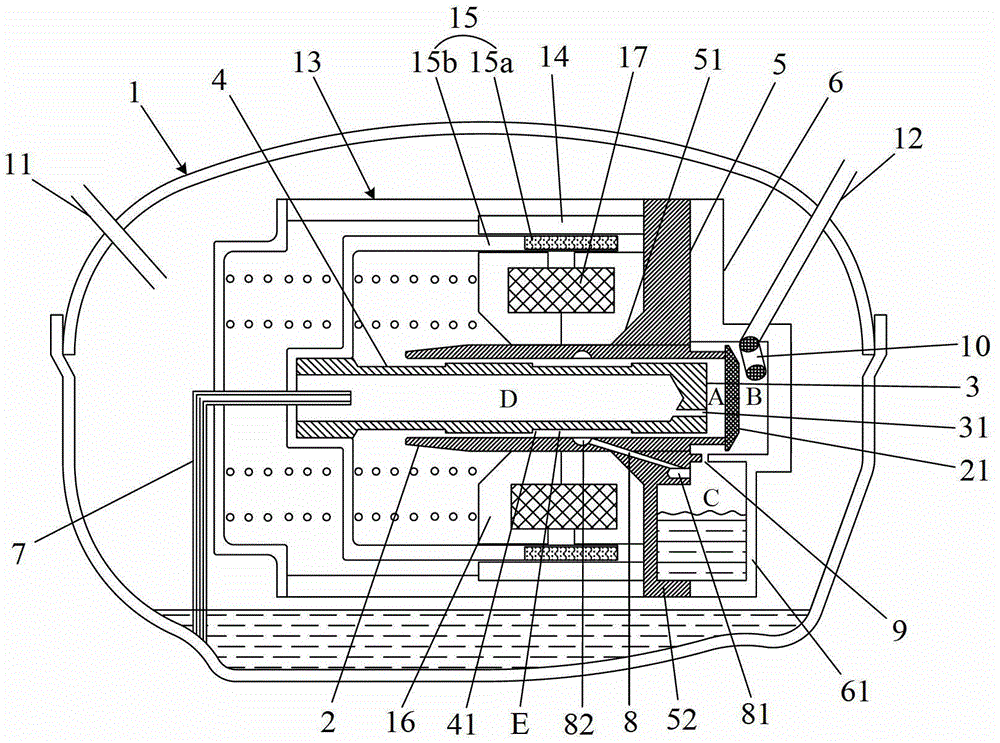

[0036] Refer below figure 2 Shown is a detailed description of the specific implementation of the linear compressor of the present invention.

[0037] Such as figure 2 As shown, both the flange 5 and the cylinder head 6 are in the shape of an asymmetric disk. The flange 5 has a flange side wall 52 located below the exhaust chamber B, and the cylinder head 6 has a flange located under the exhaust chamber B. The lower cylinder head side wall 61 is oppositely arranged with a certain distance between them, and the edge of the flange side wall 52 and the edge of the cylinder head side wall 61 are bent toward each other and butted against each other, thereby , the side wall 52 of the flange and the side wall 61 of the cylinder head jointly form a cavity, which is the oil storage cavity C. A narrow opening 9 is provided between the exhaust chamber B and the oil storage chamber C, and the two are communicated through the narrow opening 9 . Through the narrow opening 9, the circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com