Dual-heating interior spiral drum type biomass material dryer

An internal spiral and drum type technology, applied in the field of biomass energy utilization, can solve the problems of extending the length of the drying cylinder, high speed of hot air flow, and low drying efficiency, and achieve the effects of improving drying efficiency, reducing heat loss, and reducing self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

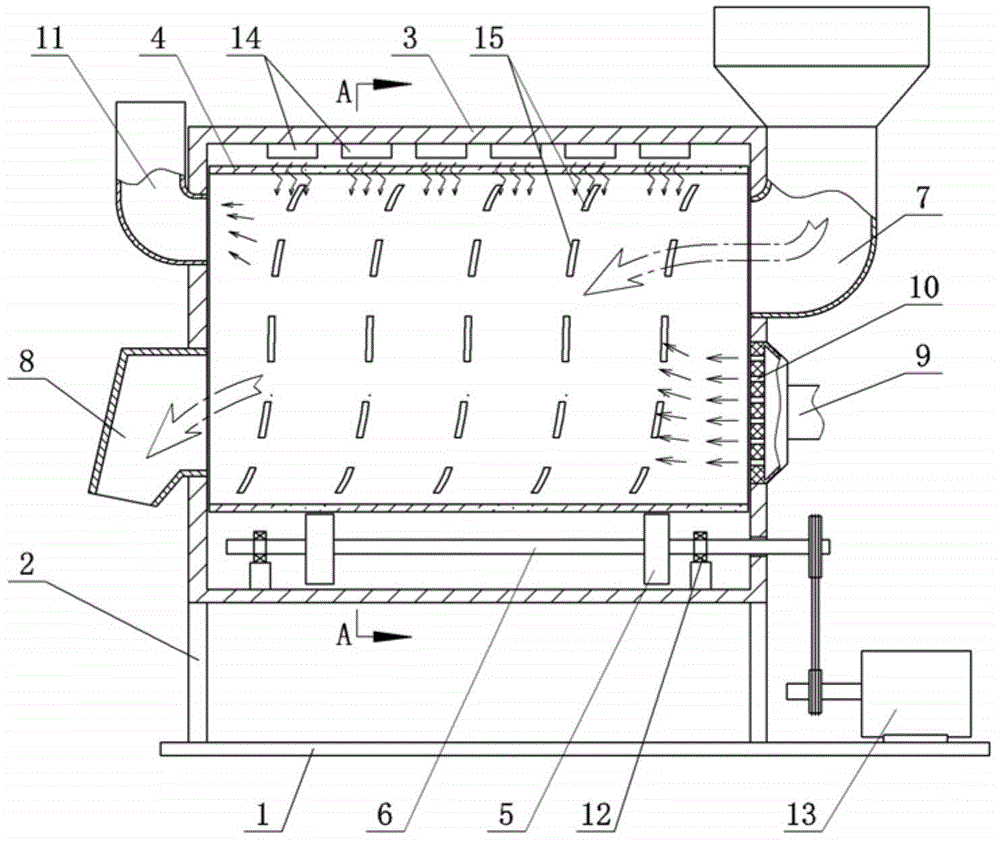

[0013] Embodiment 1: The first kind of double heating internal spiral drum type biomass material dryer, see figure 1 with figure 2 , the lower side of the bracket is fixed on the base 1, and a sealed box 3 is fixed on the bracket 2.

[0014] A heating device is provided in the sealed box 3 as a main heating source. The fixed sealing box 3 is conducive to installing the heating device, and the heating device has various weights, such as electric heating tubes and other parts that can be arranged on the bottom or both sides or top of the sealing box.

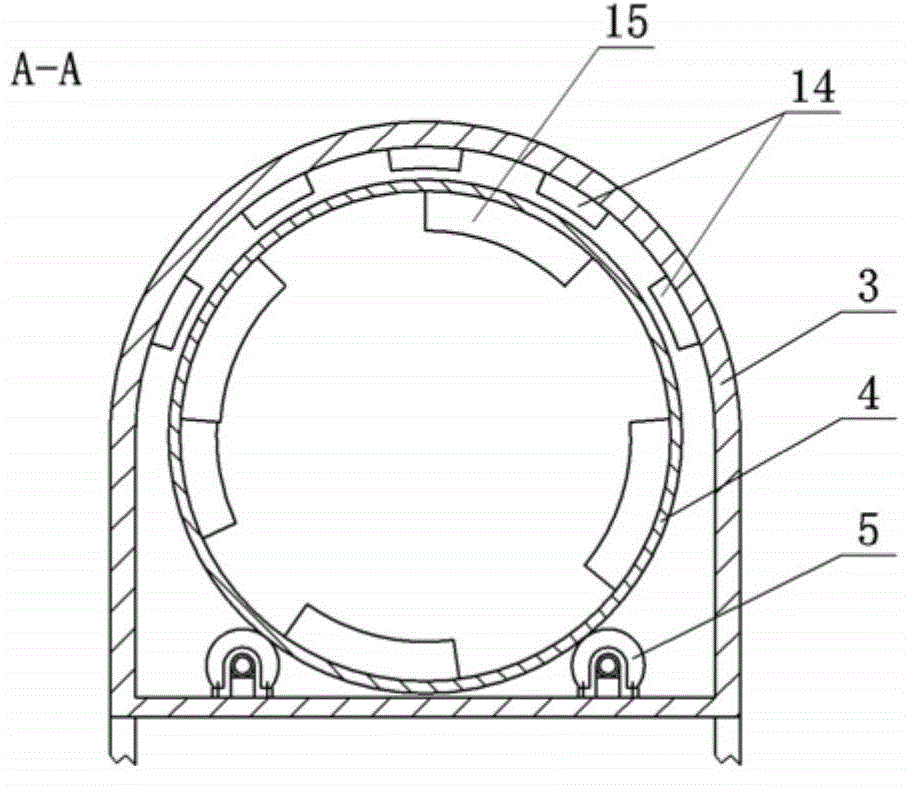

[0015] A roller 4 is installed in the sealing box 3, and the roller 4 is supported by the roller 5 and driven by the roller. The two ends of the roller 4 are open, but they slide with the inner wall of the sealing box 3. side walls at both ends. The specific structure is given by figure 2 , a pair of transmission shafts 6 parallel to the axial direction are arranged at the bottom of the sealing box 3, and each transmission s...

Embodiment 2

[0019] Embodiment 2: The second kind of double heating internal spiral drum type biomass material dryer, see figure 1 with figure 2 , the content is basically the same as that of Example 1, and the similarities will not be repeated. The difference is that the heating device is a microwave heating device 14 located at the top in the sealed box. The whole sealed box is equivalent to a microwave oven. Devices to prevent microwave leakage are installed near the feed inlet and outlet. For example, annular water chambers are respectively provided near the feed inlet and outlet.

Embodiment 3

[0020] Embodiment 3: The second kind of double heating internal spiral drum type biomass material dryer, see figure 1 with figure 2 , the content is basically the same as that of Example 1, the difference is that, on the basis of Example 1, the hot air inlet pipe 9 is set as a tapered enlarged section, and an air diffuser 10 is set in the tapered enlarged section. The air diffuser 10 is a panel with a plurality of ventilation holes evenly distributed in the middle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com