Waste gas recovery device for injection molding machine

A waste gas recovery and injection molding machine technology, applied in the direction of smoke removal, chemical instruments and methods, cleaning methods and appliances, etc., can solve problems such as polluting the air environment and endangering workers' health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

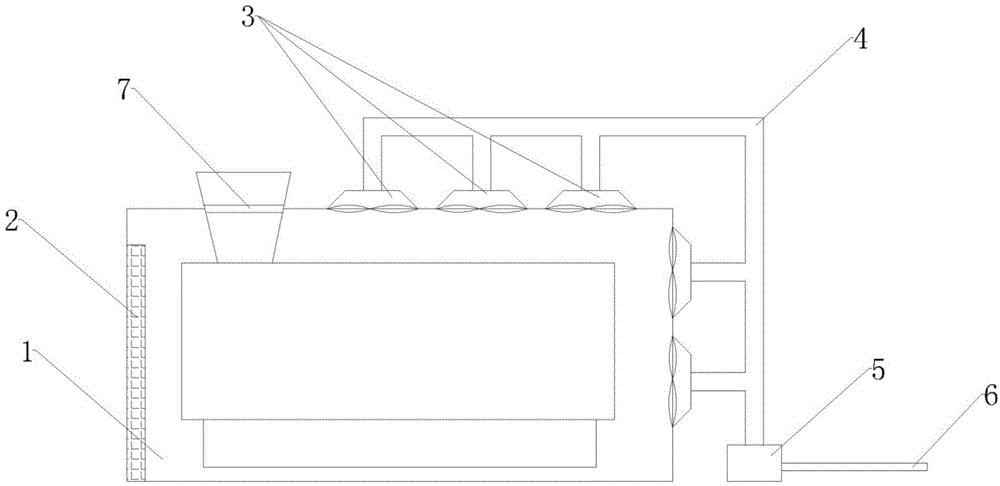

[0011] according to figure 1 The waste gas recovery device of injection molding machine shown has a sealed box body 1, a box body door 2, a number of suction devices 3, a number of waste gas pipelines 4, a waste gas treatment machine 5, a gas discharge pipe 6 and a hopper hole 7. The box body door 2 is installed on the side wall of the sealed box 1, and the several air suction devices 3 are installed on the top wall and the side door wall of the sealed box 1, and the several air suction devices 3 are connected through several exhaust gas pipes 4 Up, one end of the waste gas processor 5 is connected to the waste gas pipeline 4, and the other end is connected to the gas discharge pipe 6.

[0012] When in use, the injection molding machine is placed in the sealed box 1 of the waste gas recovery device of the injection molding machine, the hopper can stretch out from the hopper hole 7, and when the injection molding machine is working, close the box door 2. The air suction device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com