Direct-combustion heat-accumulating-type incineration treatment device and treatment method thereof

A technology of treatment device and treatment method, which can be applied to combustion methods, combustion types, incinerators, etc., and can solve problems such as high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

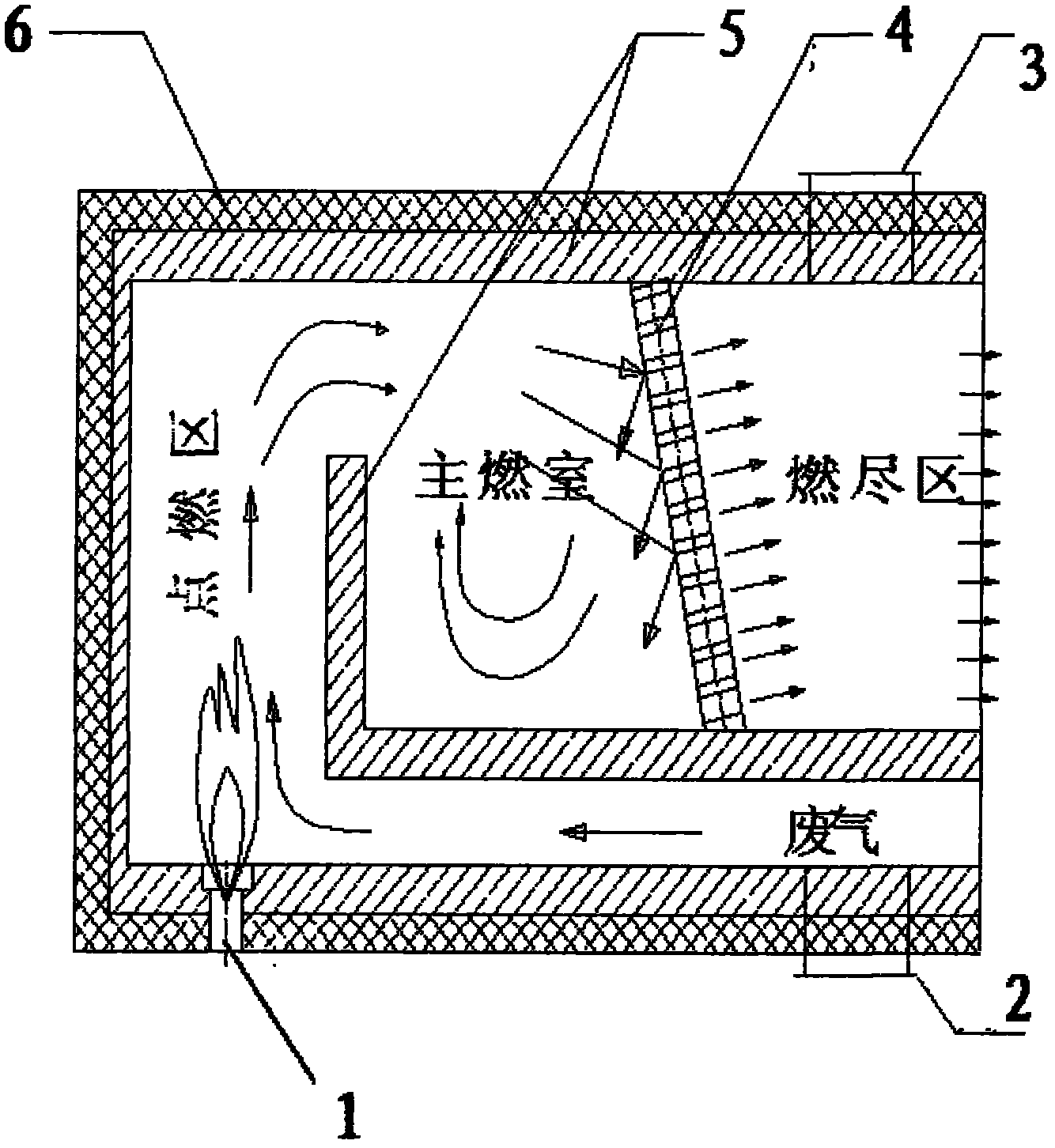

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0026] Combustion principle:

[0027] A well-organized combustion process is as close to complete combustion as possible, that is, the organic waste gas burns quickly and fully in the furnace, resulting in higher combustion efficiency. The definition of combustion efficiency is:

[0028] n r =1-(η 1 +η 2 )

[0029] In the formula, η 1 -----Chemical incomplete combustion heat loss, %

[0030] n 2 ----- Mechanical incomplete combustion heat loss, %

[0031] For complete combustion, the following conditions are required:

[0032] 1. Sufficient and appropriate amount of air: The basic condition for combustion is the oxygen content in the air, which is a necessary condition for the complete combustion of fuel. The optimal ratio of air volume and fuel is obtained through calculation and various combustion experiments, while the oxyg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com