Low vacuum ejector heat pump composite waste-heat heating supply system based on huge temperature-difference heat supply network

A heating system and ejection technology, which is applied in the heating system, hot water central heating system, space heating and ventilation, etc., can solve the problem of small temperature difference between supply and return water, inflexible heating operation adjustment, and poor energy saving effect. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

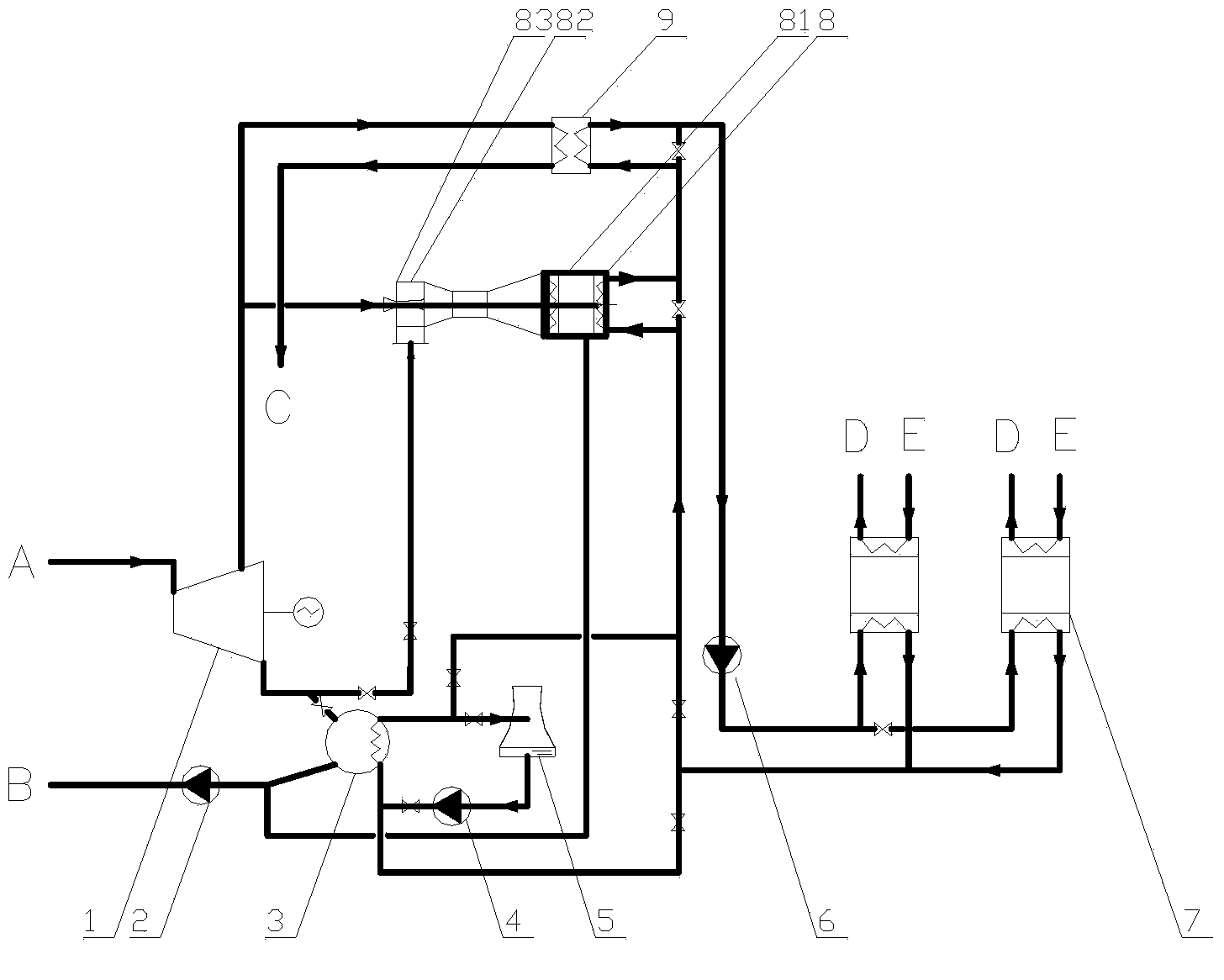

[0019] The low-vacuum injection heat pump composite waste heat heating system based on the super-large temperature difference heating network of the present invention is described in detail below with reference to the drawings and embodiments.

[0020] Concrete embodiment structure of the present invention, such as figure 1 As shown, the specific implementation and function description of this system are as follows: low-vacuum injection heat pump composite waste heat heating system based on the super-large temperature difference heating network, the system includes 8 waste heat recovery devices of the injection heat pump, as the water-based heat source of the heating network The exhaust steam direct recovery device 3, the peak regulation heater 9, the heat exchange unit with a large temperature difference in the heat network and pipeline fittings, wherein the cold side inlet of the exhaust steam direct recovery device 3 passes through the return pipe of the heat network and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com