Low-vacuum absorption-type composite heat pump residual heat supply system based on ultra-great-temperature-difference heat supply network

A technology of absorption heat pump and heating system, which is applied in heating system, hot water central heating system, space heating and ventilation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

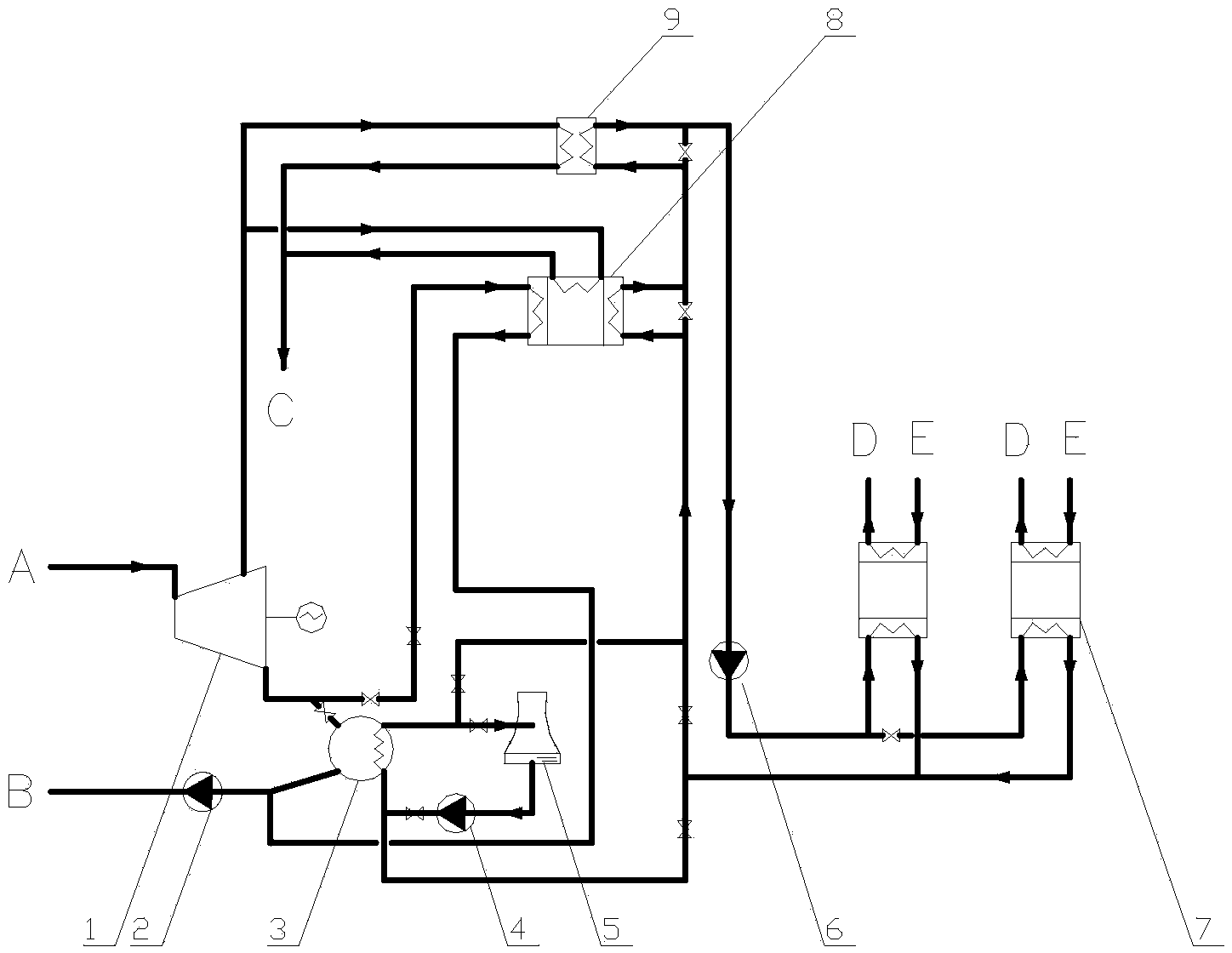

[0016] The low-vacuum absorption heat pump composite waste heat heating system based on the ultra-large temperature difference heating network of the present invention is described in detail below with reference to the drawings and embodiments.

[0017] Concrete embodiment structure of the present invention, such as figure 1 shown. The specific implementation and function description of this system are as follows: low vacuum absorption heat pump composite waste heat heating system based on super large temperature difference heat network, mainly including absorption heat pump waste heat recovery, peak regulation heater and heat network super large temperature difference heat exchange unit and pipe The pipe fittings also include the exhaust steam direct recovery device 3 as the water-based heat-carrying source of the heating network. The circulating cooling water pipe is connected to the water supply outlet of the cooling tower 5, the cold side outlet of the exhaust steam direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com