Open type compression absorption heat pump system for water heat recovery in high-temperature and high-humidity gas

A high-temperature, high-humidity, heat recovery technology, which is applied in the fields of environmental protection, waste heat utilization, and heat exchange, can solve the problems of condensation, poor energy efficiency, and power reduction, etc., to improve the efficiency of water heat recovery and increase the latent heat of vaporization , the effect of large vapor pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

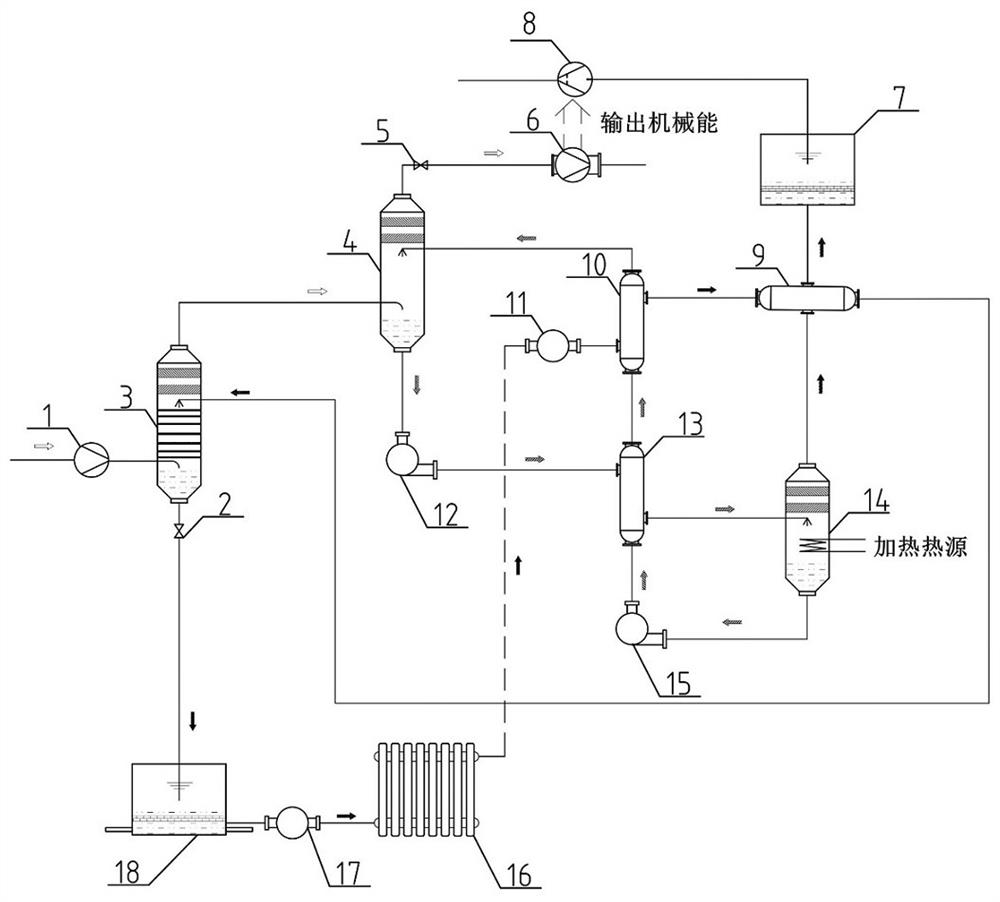

[0036] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0037] figure 1 An open compression absorption heat pump system for water heat recovery from high-temperature and high-humidity gas is demonstrated. Such as figure 1 As shown, the system includes a gas pressure regulating device 1, a contact heat exchanger 3, pressure control valves 2 and 5, an expander 6, an absorber 4, a solution water heat exchanger 10, a solution heat exchanger 13, and a condenser 9. Regenerator 14 , condensed water tank 7 , vacuum pump 8 , circulating water tank 18 and user-end heat output device 16 . The outlet of the gas pipeline is connected to the contact heat exchanger 3, and the gas pressure regulating device 1 is arranged on the gas pipeline, the contact heat exchanger 3 is connected to the absorber 4, and the gas outlet at the upper end of the absorber 4 is connected to the expander 6, and the absorber 4 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com