Flue gas condenser

A flue gas condenser and condenser technology, applied in water shower coolers, heat exchanger types, indirect heat exchangers, etc., can solve the problem of condensed water corrosion, limited heating area and heat transfer efficiency, and inability to condense flue gas Water vapor effect and other issues, to achieve the effect of preventing erosion, prolonging the service life and avoiding premature damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

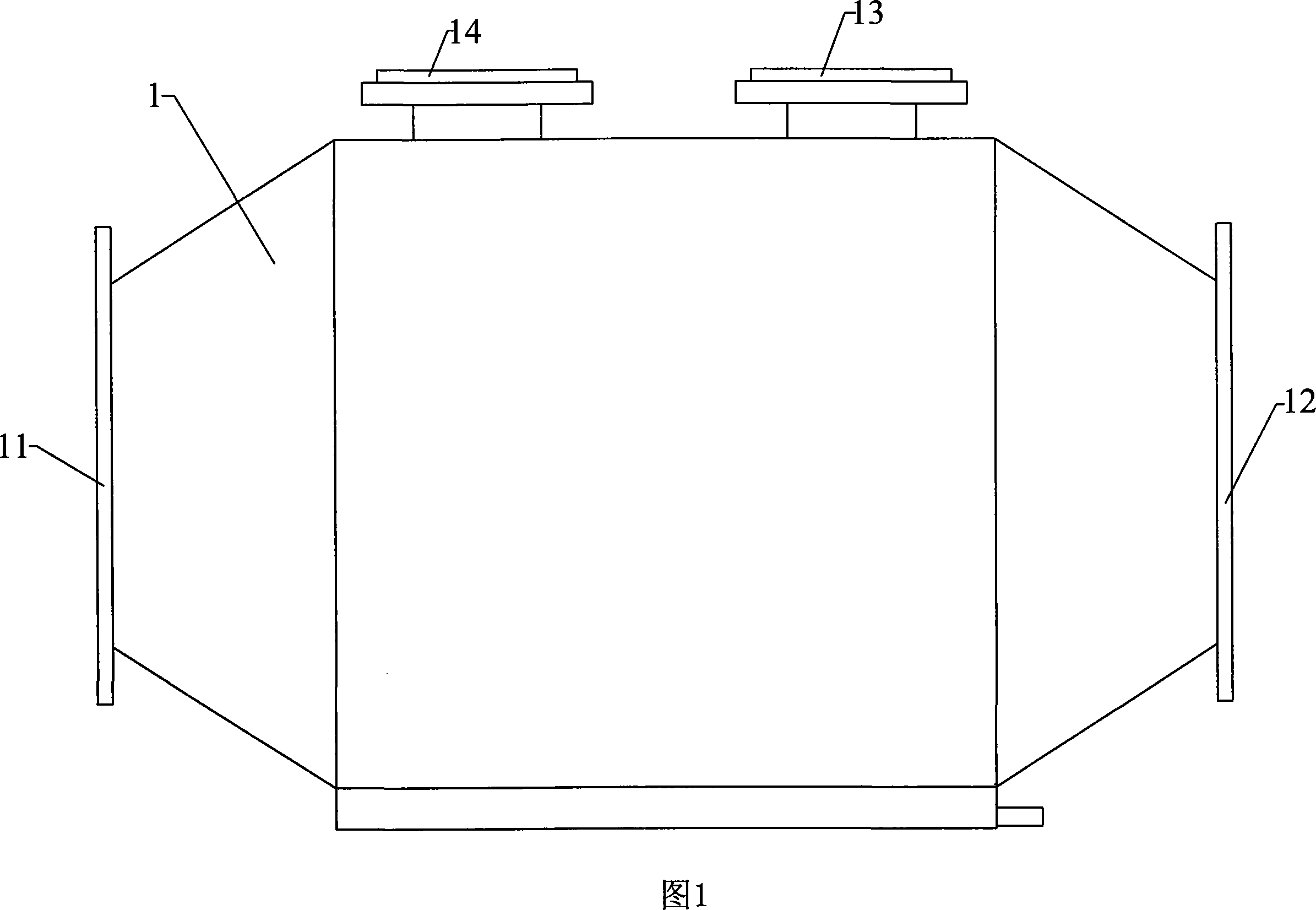

[0023] As shown in Figure 1, the present invention is a new type of flue gas condenser, which includes a shell 1 made of glass fiber reinforced plastics, or the inner cavity is lined or coated with anti-corrosion materials. The casing 1 is provided with a flue gas inlet 11 , a flue gas outlet 12 , a cooling water inlet 13 and a cooling water outlet 14 . Among them, the flue gas inlet 11 and the flue gas outlet 12 are horizontally arranged at both ends of the casing, the cooling water inlet 13 and the cooling water outlet 14 are radially arranged on the top of the casing, and the cooling water inlet 13 and the flue gas outlet 12 are located on the same side, cooling The water outlet 14 and the flue gas inlet 11 are located on the same side. Cooling water and flue gas are arranged in countercurrent.

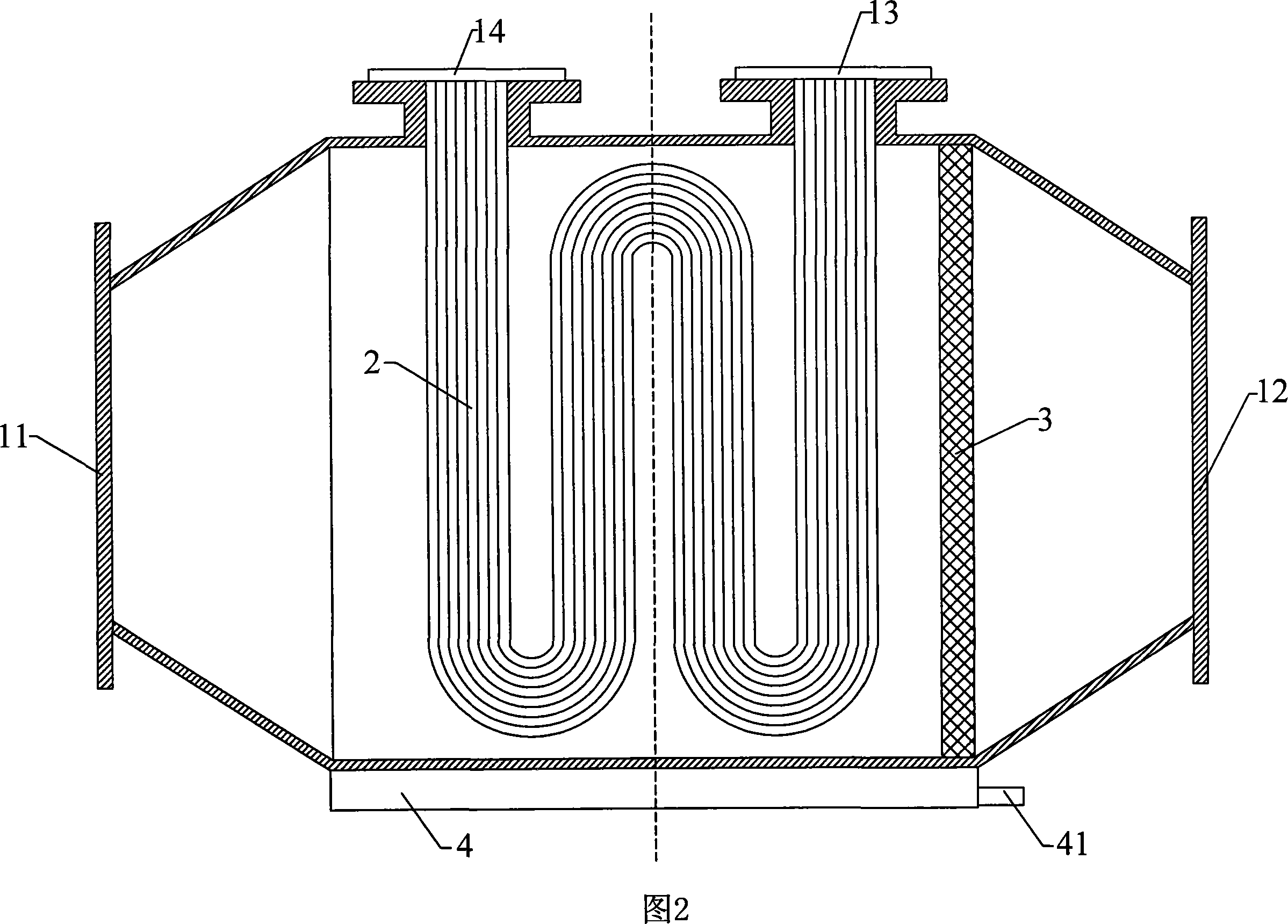

[0024] As shown in Figure 2, the middle part of the condenser is provided with a heat exchange element 2, the heat exchange element 2 is a coiled capillary made of polytetrafluoro...

Embodiment 2

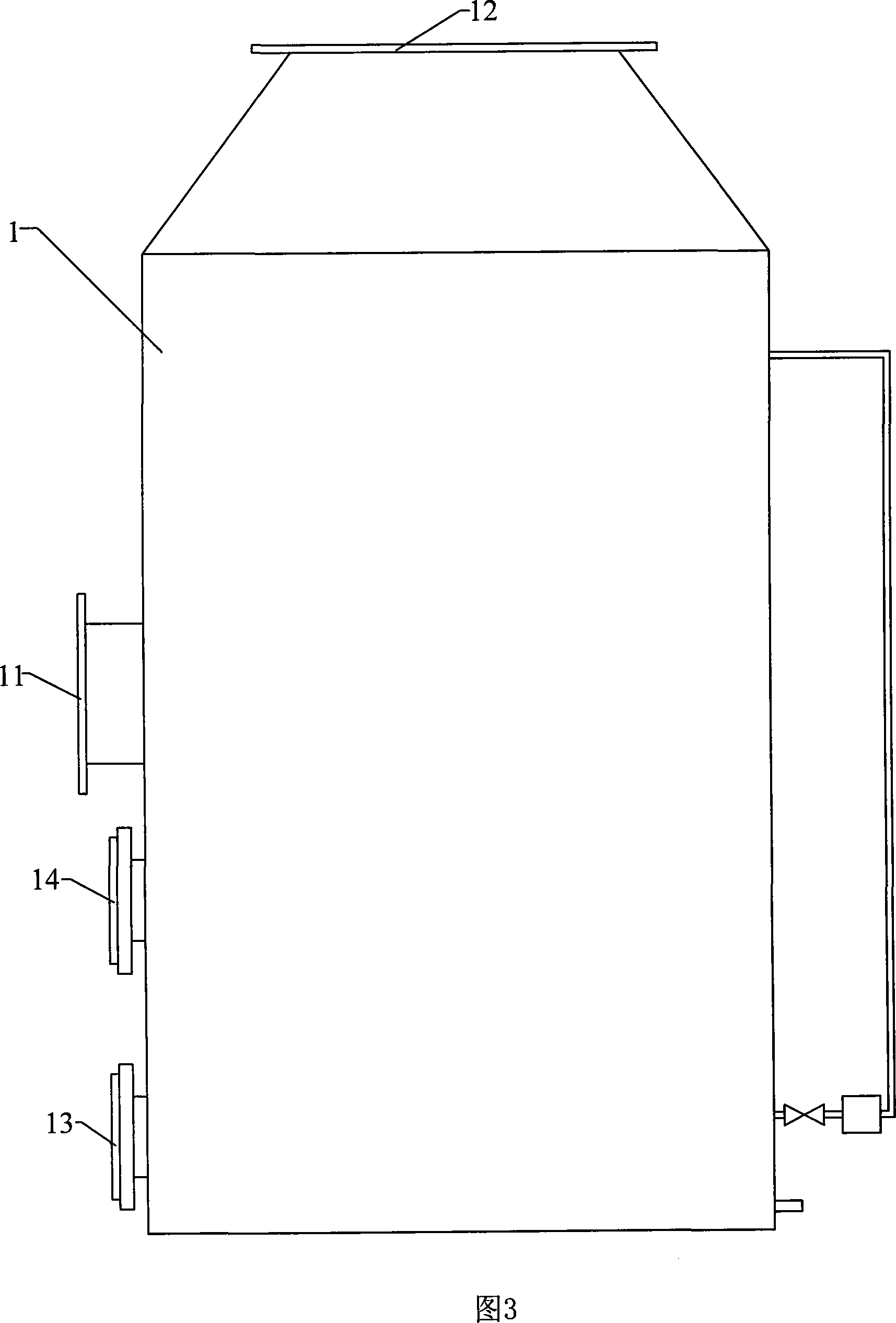

[0029] As shown in Fig. 3, this embodiment is another embodiment of the present invention. Wherein, the flue gas outlet 12 is radially arranged on the top of the casing 1, the flue gas inlet 11 is arranged on the side wall of the casing 1, the cooling water inlet 13 and the cooling water outlet 14 are arranged on the spray water tank of the spray device described below, and the cooling water inlet 13 is located below the cooling water outlet 14. Cooling water and spray water are arranged in countercurrent.

[0030] As shown in Fig. 4, this condenser is also provided with spraying device 5, and it comprises: - has the spray tank 55 of water level monitor, is located at the bottom of condenser, is built-in the coil type capillary tube that polytetrafluoroethylene is made , the two ends of the capillary are respectively connected with the cooling water inlet 13 and the cooling water outlet 14 arranged on the spray water tank, while the minimum water level in the spray water tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com