Textile fabric printing and dyeing equipment and operation method thereof

A technology of printing and dyeing equipment and operation method, applied in the field of textile printing and dyeing, can solve the problems of increasing the cost of fabric printing and dyeing, and achieve the effects of reducing fluff, being easily heated, and having a smooth surface of the fabric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

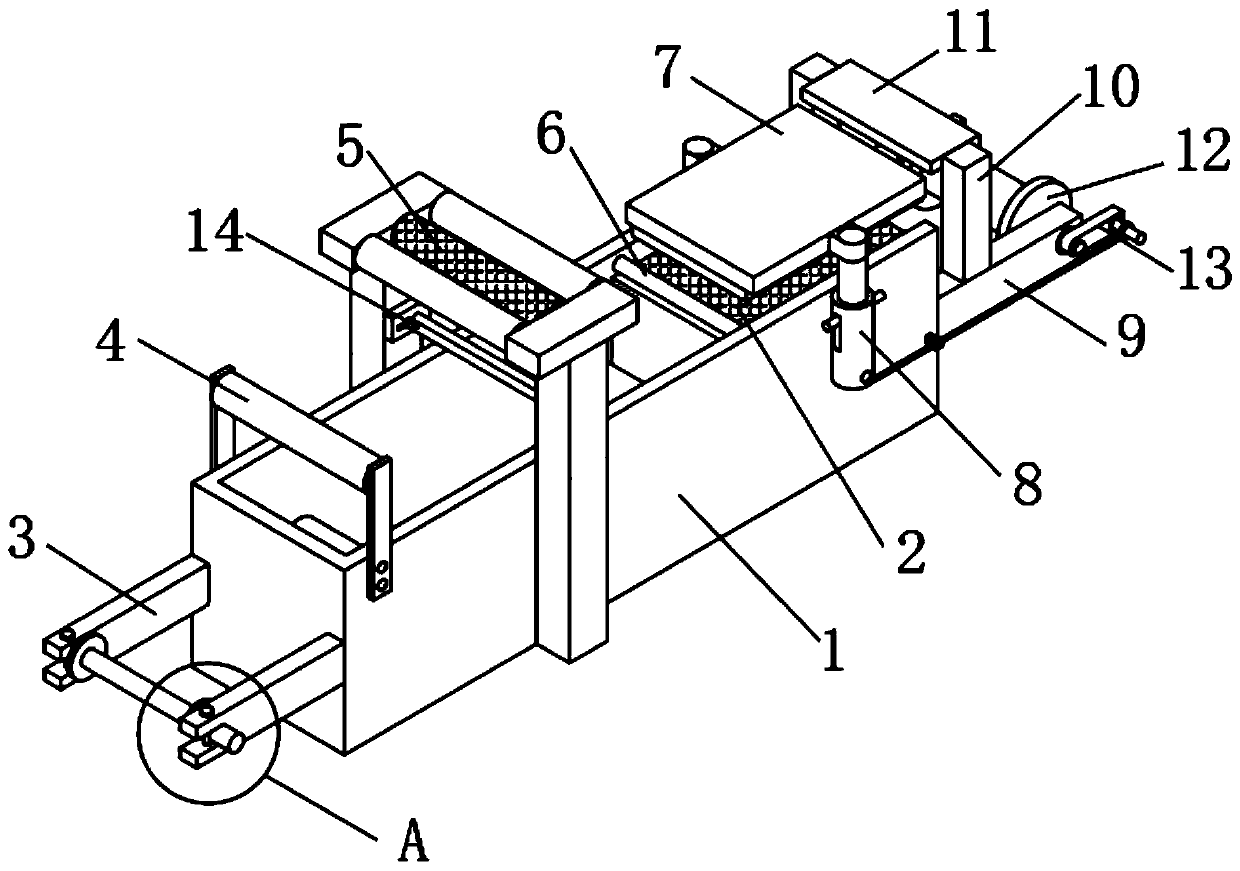

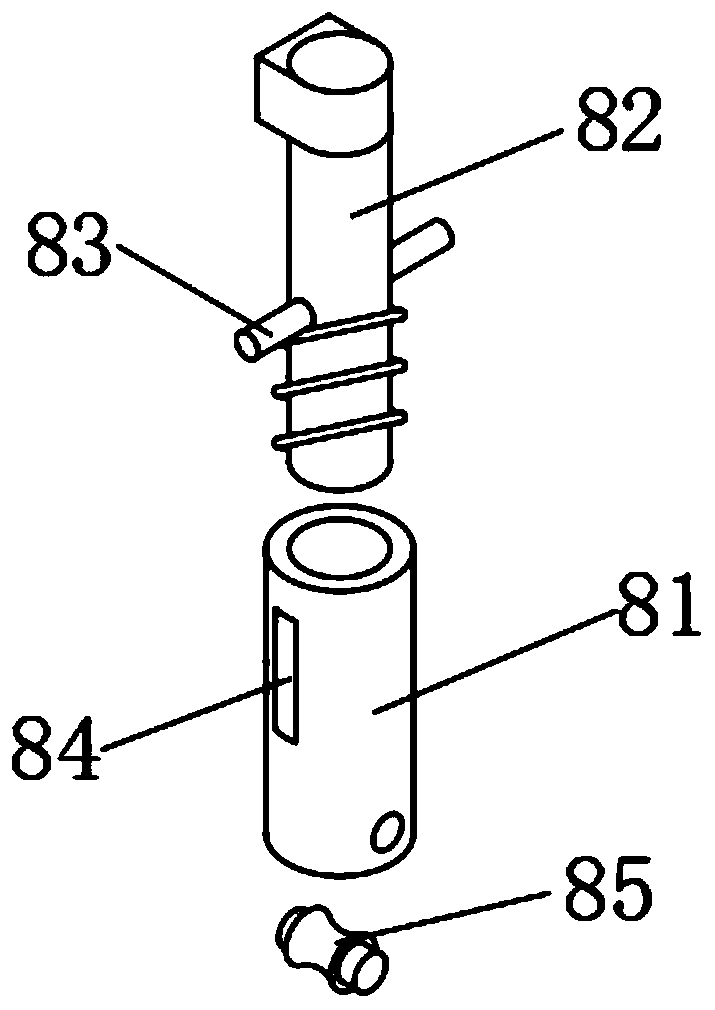

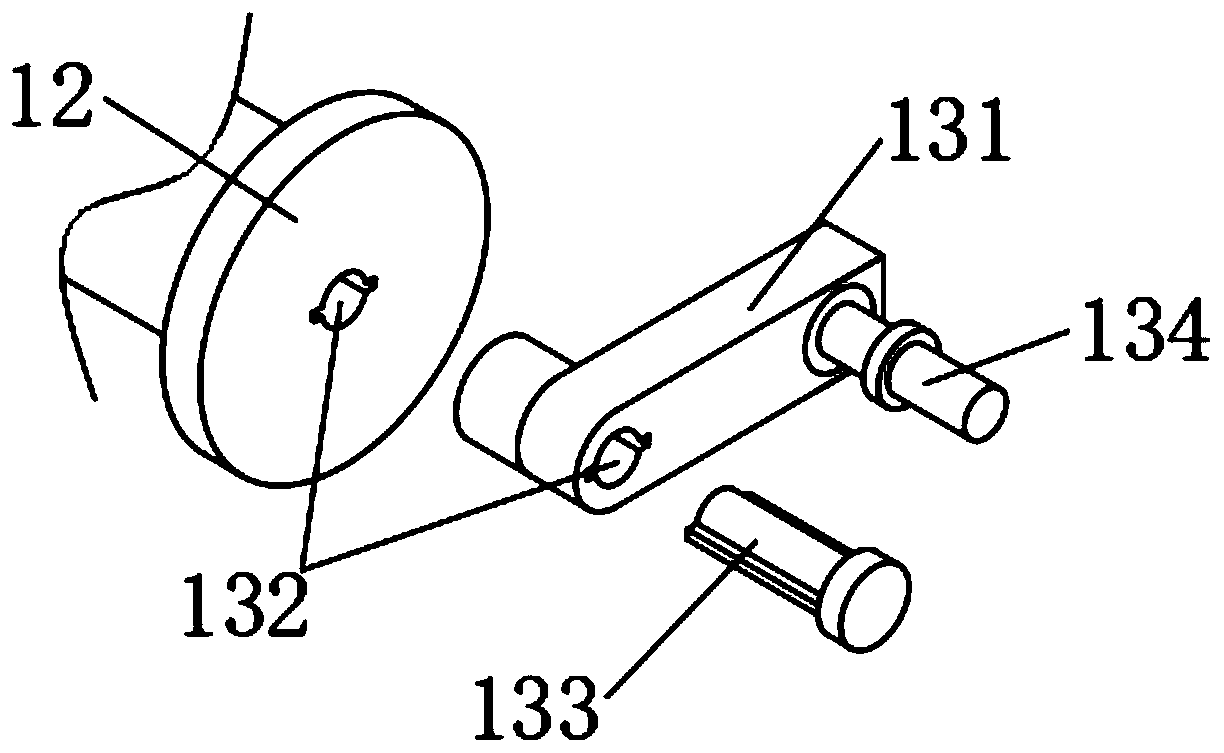

[0033] see Figure 1-6, the present invention provides a technical solution: a textile fabric printing and dyeing equipment, including a dyeing tank 1 and a printing table 2; the printing table 2 is fixedly connected to the side of the dyeing tank 1, and the side of the dyeing tank 1 away from the printing table 2 is fixedly connected Feeding rod 3, the upper surface of dyeing tank 1 is fixedly connected with retaining roller 4, the upper surface of dyeing tank 1 and is located at the side of retaining roller 4 close to printing table 2 is fixedly connected with press cloth assembly 5, the printing table 2 The upper surface and the side close to the dyeing tank 1 are rotatably connected with a pressure roller 6, the upper surface of the printing table 2 is provided with a printing plate 7, and both sides of the printing plate 7 are fixedly connected with a lifting assembly 8, and the bottom end of the lifting assembly 8 Fixedly connected to the side of the printing table 2, th...

Embodiment 2

[0038] see Figure 1-6 , the present invention provides a technical solution: a method of operating textile fabric printing and dyeing equipment. When the present invention is in use, step 1, firstly carry out cloth installation, wind the cloth to be printed and dyed on the outer surface of the feeding roller 17, and then Pull up the fixed bar 18 on the upper surface of the fixed groove 16, and then move the feeding roller 17 into the inside of the fixed groove 16, then pass the end of the cloth through the upper surface of the material blocking roller 4, and then pass it from the electric heating roller. 52 and the left side pressure roller 53 pass, then enter down in the dyeing tank 1, walk around from the dyeing nip roller 15 at the left end of the dyeing tank 1, then pass through the bottom of the dyeing nip roller 15 at the right end of the dyeing tank 1, Then pass upwards from the right side of the dyeing nip roller 15 at the right end, then pass between the first wiper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com