Multi-component alloy melting and mixing device

A mixing device and multi-alloy technology, applied in the field of alloy deep processing, can solve the problems of difficult melting and large metal particles, and achieve the effects of easy melting, good quality and easy heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

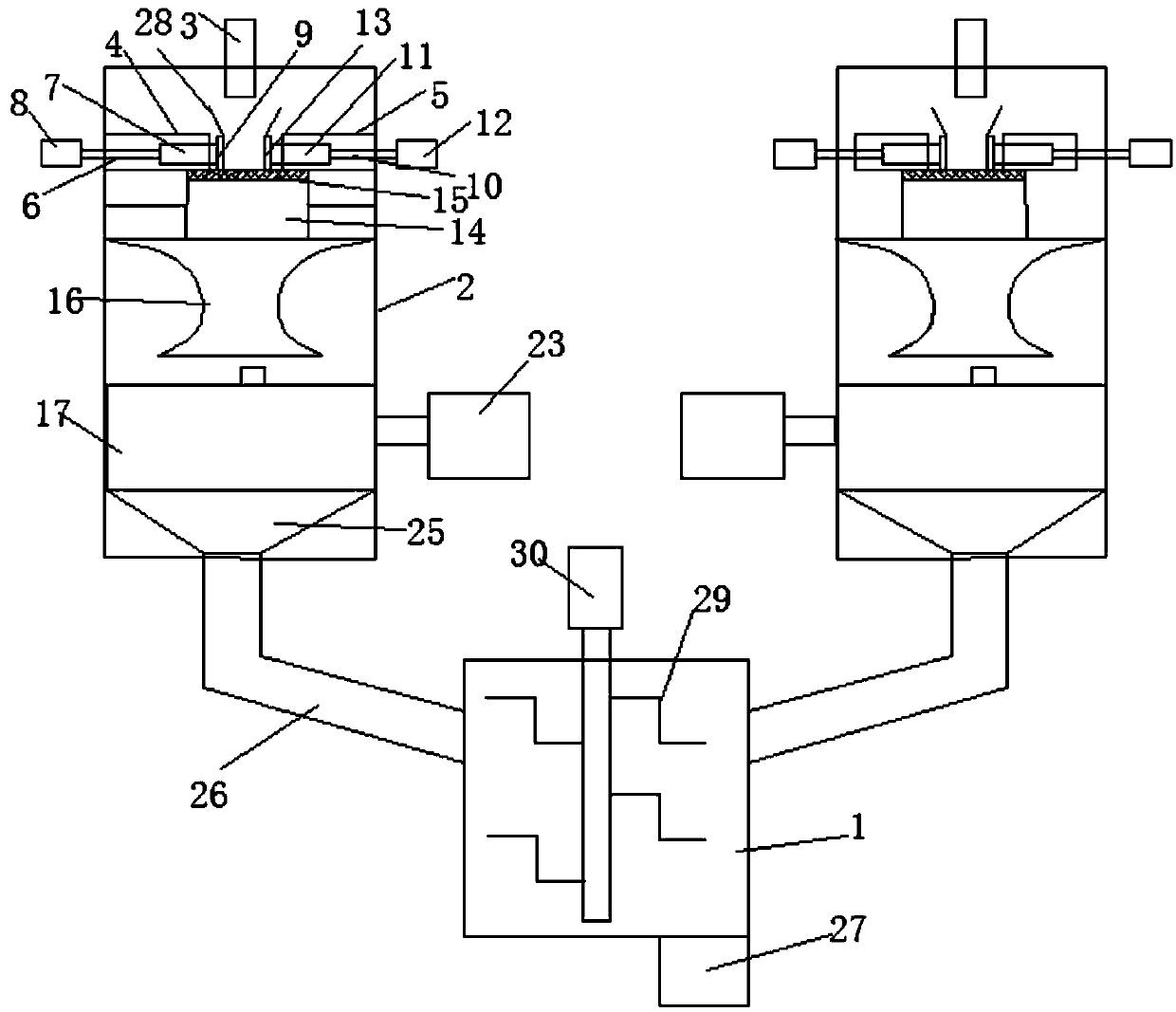

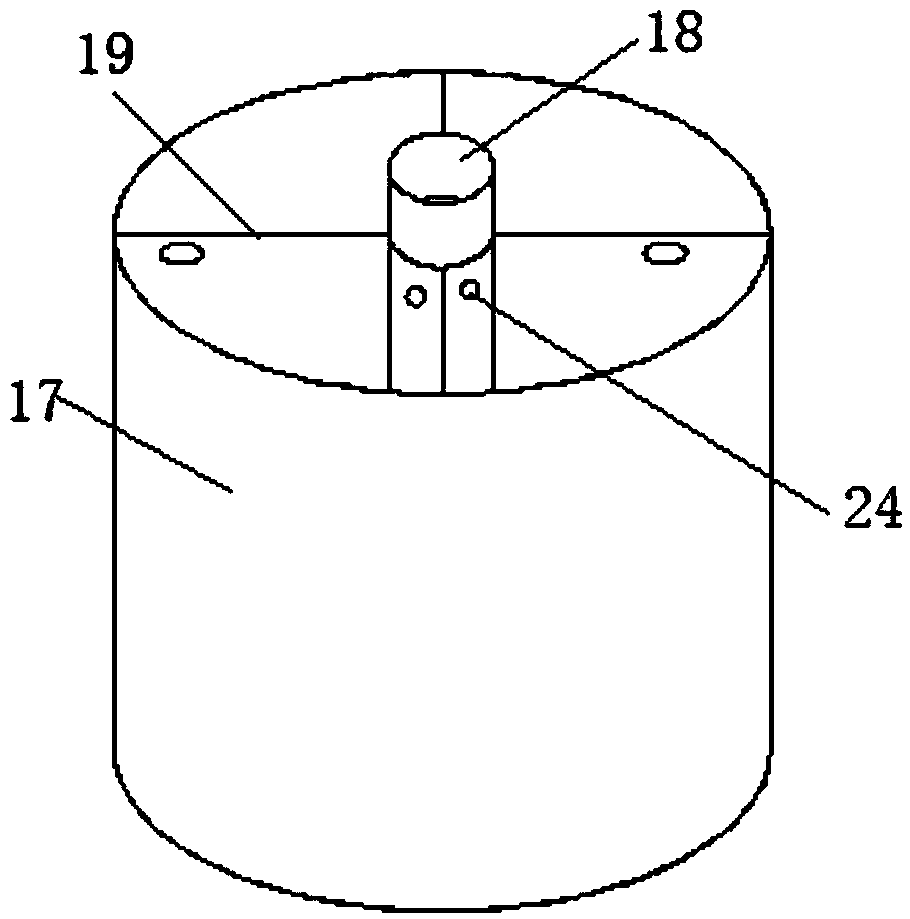

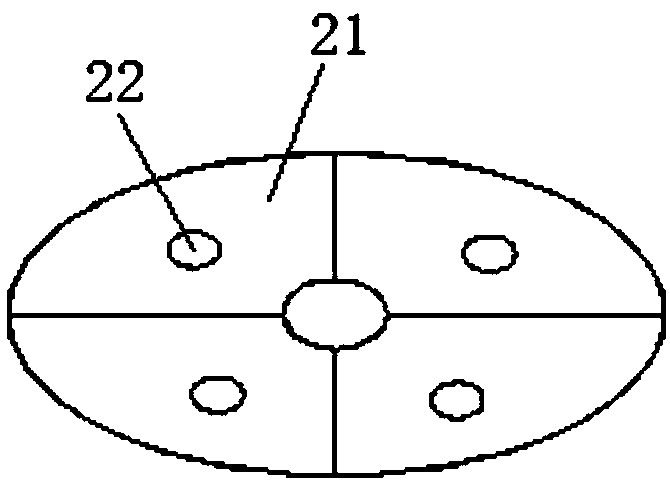

[0016] like figure 1 , 2 , Shown in 3 and 4, a multi-element alloy melting and mixing device includes a mixing drum 1 and a plurality of metal melting furnaces, the metal melting furnaces include a shell 2, and the top of the shell 2 is provided with a feed inlet 3. There is a crushing device below the feed port 3, and the crushing device includes a first guide cylinder 4 and a second guide cylinder 5 located at the same height and opposite to each other. The left end of the first guide cylinder 4 and the second The right end of the guide cylinder 5 is respectively fixedly connected to the inner wall of the housing 2, and the first pull rod 6 and the first compression column 7 are arranged inside the first guide cylinder 4, and the left end of the first pull rod 6 protrudes from the housing 2 and is connected with a second A cylinder 8, the right end of the first pull rod 6 is fixedly connected to the left end of the first compression column 7, and the right end of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com