High-temperature smelting furnace for metallurgical machinery

A high-temperature smelting and mechanical technology, used in furnaces, crucible furnaces, furnace components, etc., can solve problems such as energy waste and emission, and achieve the effects of reducing energy consumption, reducing speed, and facilitating melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

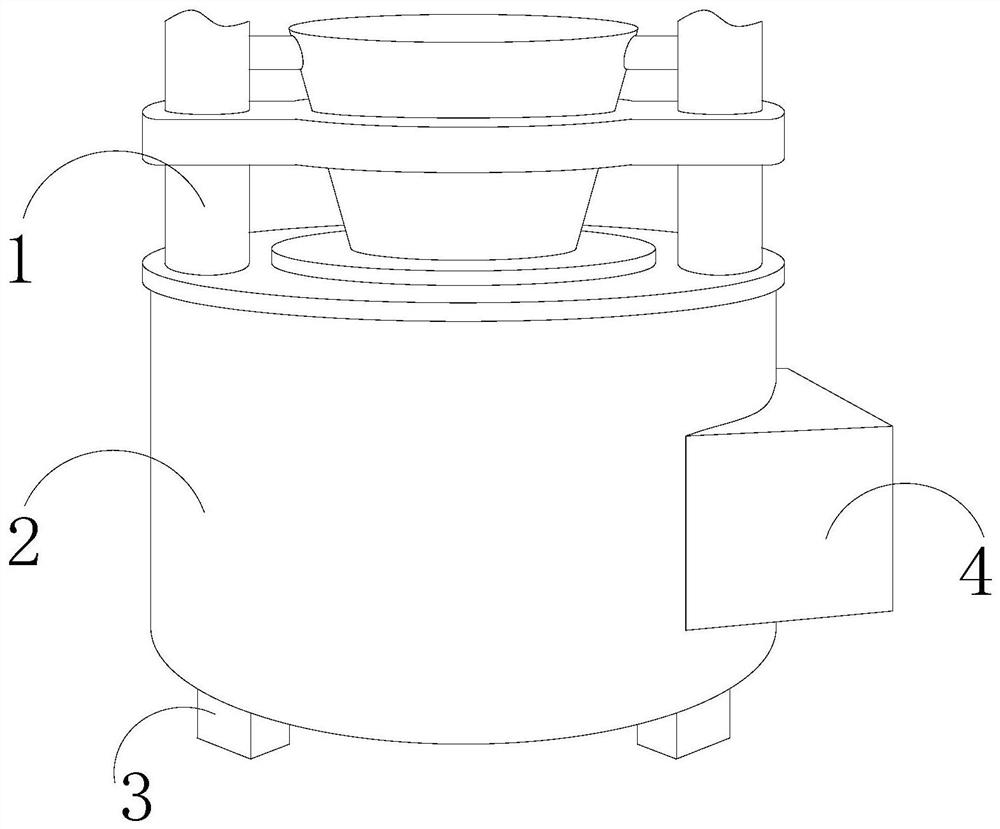

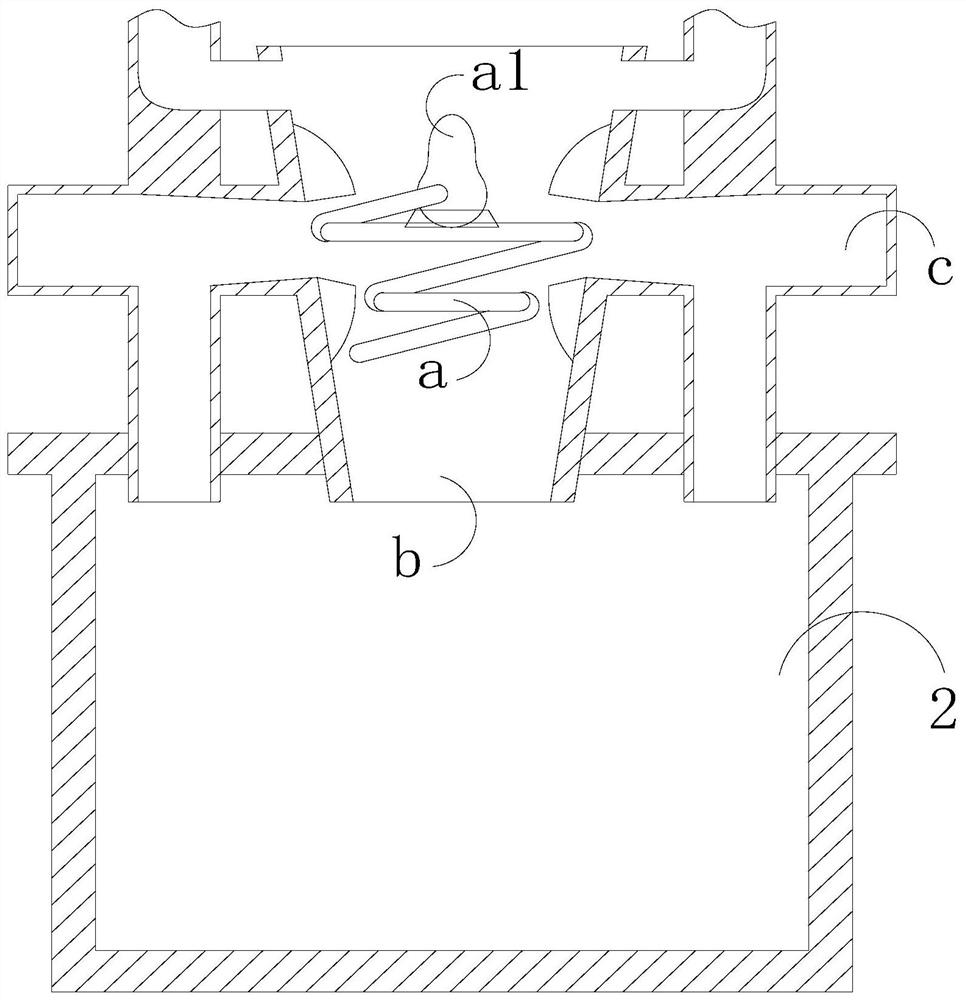

[0026] See Figure 1 - Figure 6 The present invention provides a high-temperature melt furnace for metallurgical mechanism, including the remaining heat transfer device 1, the furnace 2, the support pin 3, the adapter end 4, the remaining heat transfer device 1 is provided on the furnace 2, the furnace 2 and the waste heat The support pin 3 is fixedly mounted at the bottom of the furnace 2 by means of means 1, and the furnace 2 is fixedly provided with an adapter end 4;

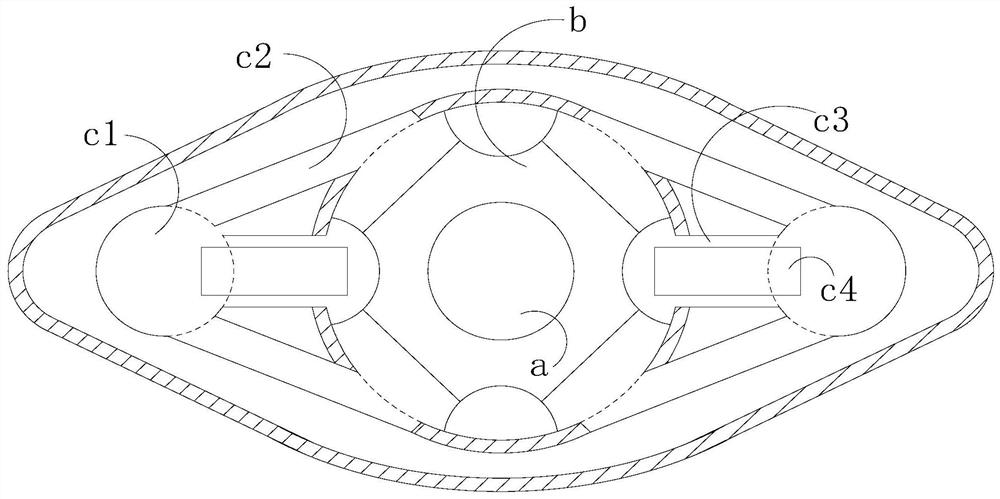

[0027] The remaining heat utilization device 1 is composed of a feed disc A, a feed channel B, an exhaust pipe C, which is provided in the feed channel B, and the feed channel B is "V" shaped round counter structure. Shape, the feed channel B is in communication with the furnace 2, the exhaust conduit C, is connected to the feed passage B, and the exhaust pipe C is in communication with the furnace 2.

[0028] The feed plate A is configured by a central block A1, a auxiliary beam plate A2, and the central block A1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com