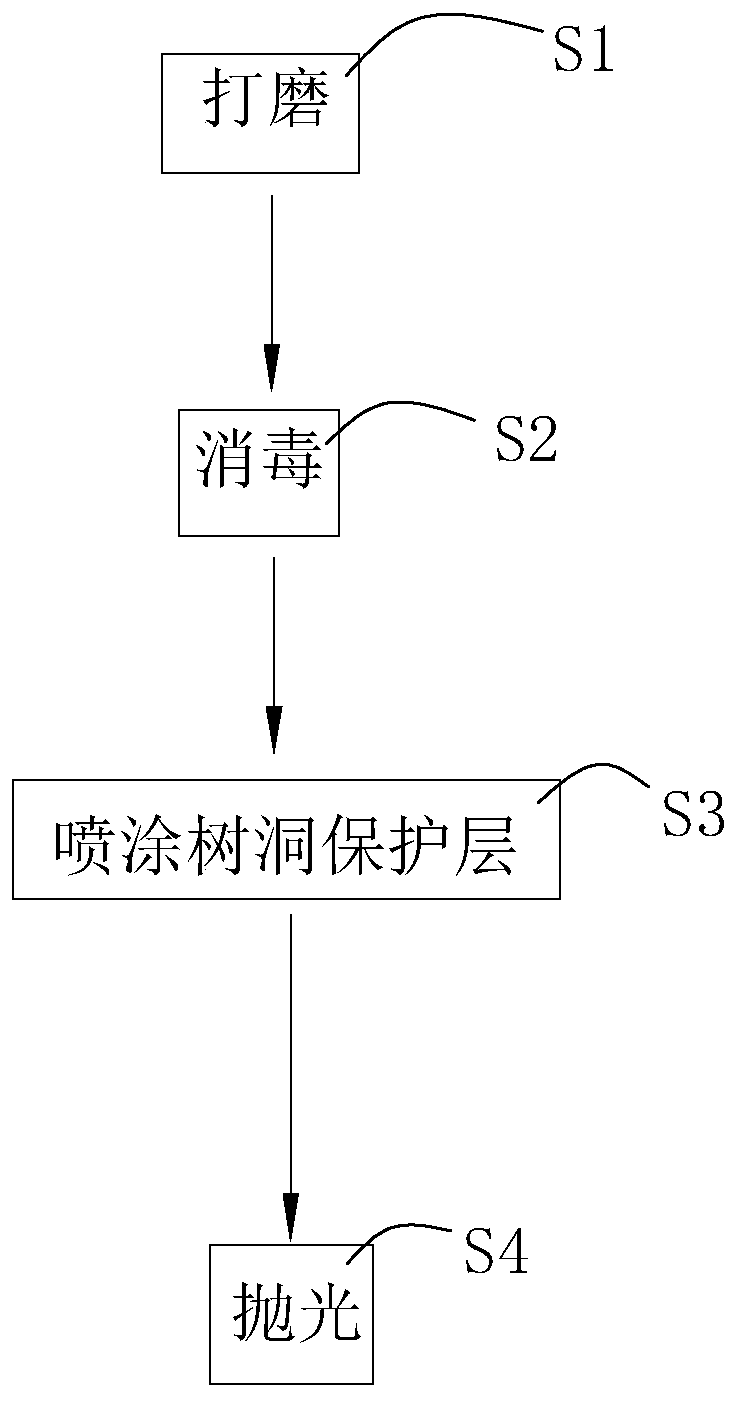

Tree hole repair method for rejuvenation of ancient trees

A construction method and technology for tree holes, which are applied in gardening methods, botanical equipment and methods, applications, etc., can solve the problems of surface decay of tree holes, affecting tree growth, and difficulty in ensuring ventilation effects in corners, so as to achieve non-permanent decay, Long service life, reduced low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A protective layer composition, the preparation method of the protective layer composition protects the following steps:

[0056] a. Grinding, as follows:

[0057] Add polyacrylonitrile, polyphthalamide and hydroxyethyl cellulose into a grinder and grind them into powders with a particle size of 10-100 nm.

[0058] b. Mixing, as follows:

[0059] Add 20kg of paraffin wax to the stirred tank and heat it to 70°C. After the paraffin wax is completely melted, add 100kg of polypropylene particles, 15kg of polyacrylonitrile powder, 12kg of polyphthalamide powder and 3kg of hydroxyethyl cellulose powder at a speed of 45r. / min, stirring for 10min to form a premix.

[0060] c. Extrusion granulation, as follows:

[0061] The premix was discharged into a twin-screw extruder, heated to 150° C., extruded into underwater granulation and granulated to form a protective layer composition.

Embodiment 2

[0063] A protective layer composition, the preparation method of the protective layer composition protects the following steps:

[0064] a. Grinding, as follows:

[0065] Add polyacrylonitrile, polyphthalamide and hydroxyethyl cellulose into a grinder and grind them into powders with a particle size of 10-100 nm.

[0066] b. Mixing, as follows:

[0067] Add 25kg of paraffin wax into the stirred tank and heat it to 70°C. After the paraffin wax is completely melted, add 100kg of polypropylene particles, 17.5kg of polyacrylonitrile powder, 16.5kg of polyphthalamide powder and 4kg of hydroxyethyl cellulose powder. Rotate at 45r / min, stir for 10min to form a premix.

[0068] c. Extrusion granulation, as follows:

[0069]The premix was discharged into a twin-screw extruder, heated to 150° C., extruded into underwater granulation and granulated to form a protective layer composition.

Embodiment 3

[0071] A protective layer composition, the preparation method of the protective layer composition protects the following steps:

[0072] a. Grinding, as follows:

[0073] Add polyacrylonitrile, polyphthalamide and hydroxyethyl cellulose into a grinder and grind them into powders with a particle size of 10-100 nm.

[0074] b. Mixing, as follows:

[0075] Add 30kg of paraffin wax to the stirred tank and heat it to 70°C. After the paraffin wax is completely melted, add 100kg of polypropylene particles, 20kg of polyacrylonitrile powder, 18kg of polyphthalamide powder and 5kg of hydroxyethyl cellulose powder at a speed of 45r / min, stirring for 10min to form a premix.

[0076] c. Extrusion granulation, as follows:

[0077] The premix was discharged into a twin-screw extruder, heated to 150° C., extruded into underwater granulation and granulated to form a protective layer composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com