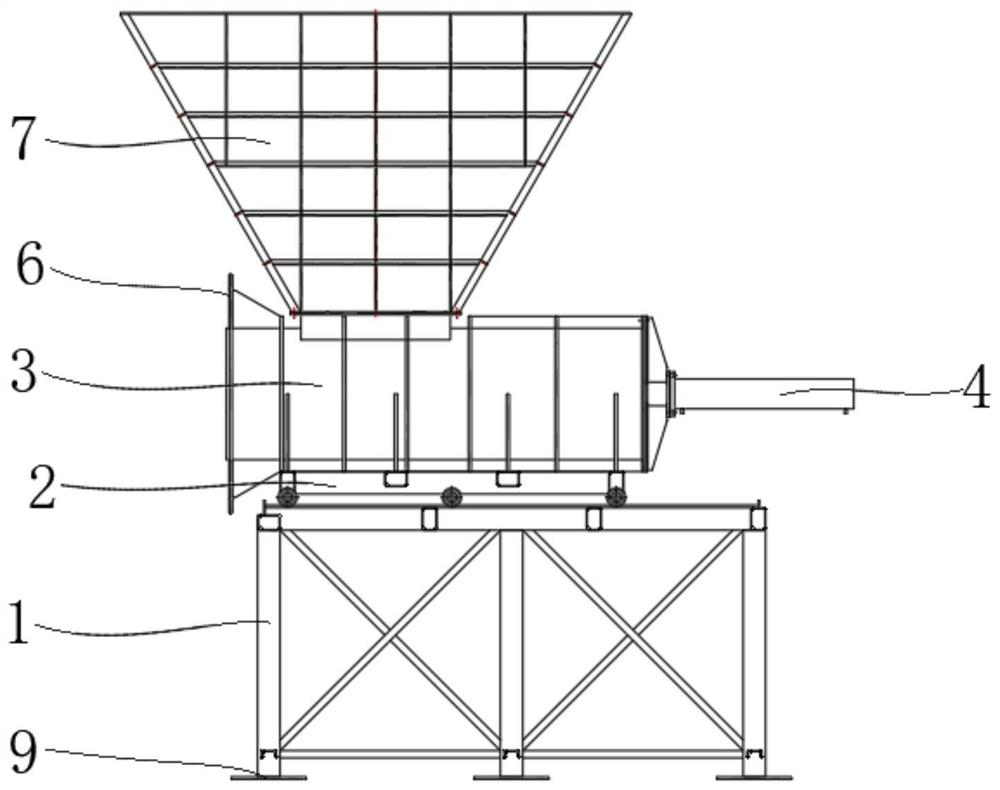

Self-sealing type hydraulic charging machine

A feeder, self-sealing technology, applied in the field of feeder, can solve the problems of affecting heating efficiency, furnace heat loss, labor intensity and high equipment operation cost, and achieve the effect of improving combustion efficiency, reducing furnace temperature loss, and easy melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

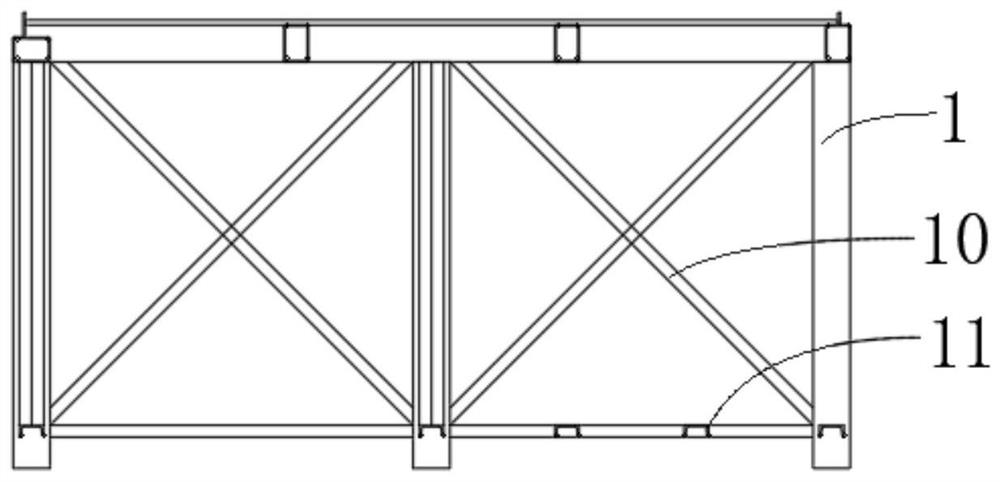

[0034] Embodiment 1: Reinforcing ribs are provided on the outside of the feeding cylinder 3 to increase the compressive load of the feeding cylinder 3 .

[0035] Working process of the present invention is as follows:

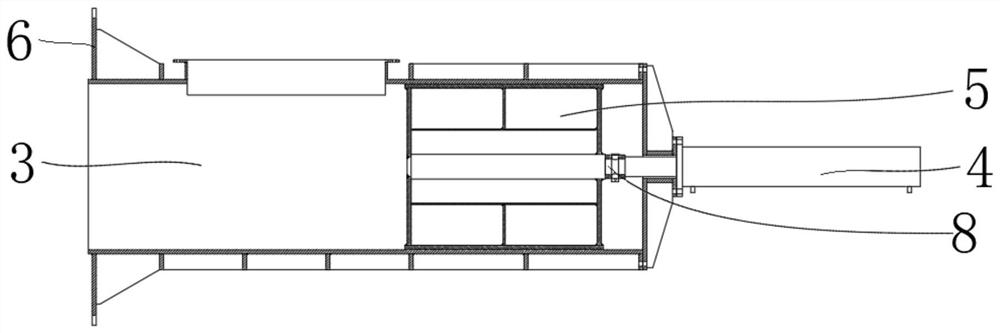

[0036] S1. Connect one end of the feeding cylinder 3 to the fuel inlet of the burner,

[0037] S2. Add fuel into the feeding barrel 3 through the feeding cover 7, and then push the fuel into the burner through the cooperation of the hydraulic cylinder 4 and the piston 5.

[0038] To sum up: the self-closing hydraulic feeder makes the piston 5 reciprocate in the feeding cylinder 3 through the action of the hydraulic cylinder 4, and pushes the aluminum material that enters the feeding cylinder 3 from the feeding cover 7 into the furnace. Melting, to realize automatic feeding, the feeding cover 7 is set on the side close to the burner so that the fuel entering the feeding cylinder 3 can be preheated by the burner flue gas, effectively reducing energy consumption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com