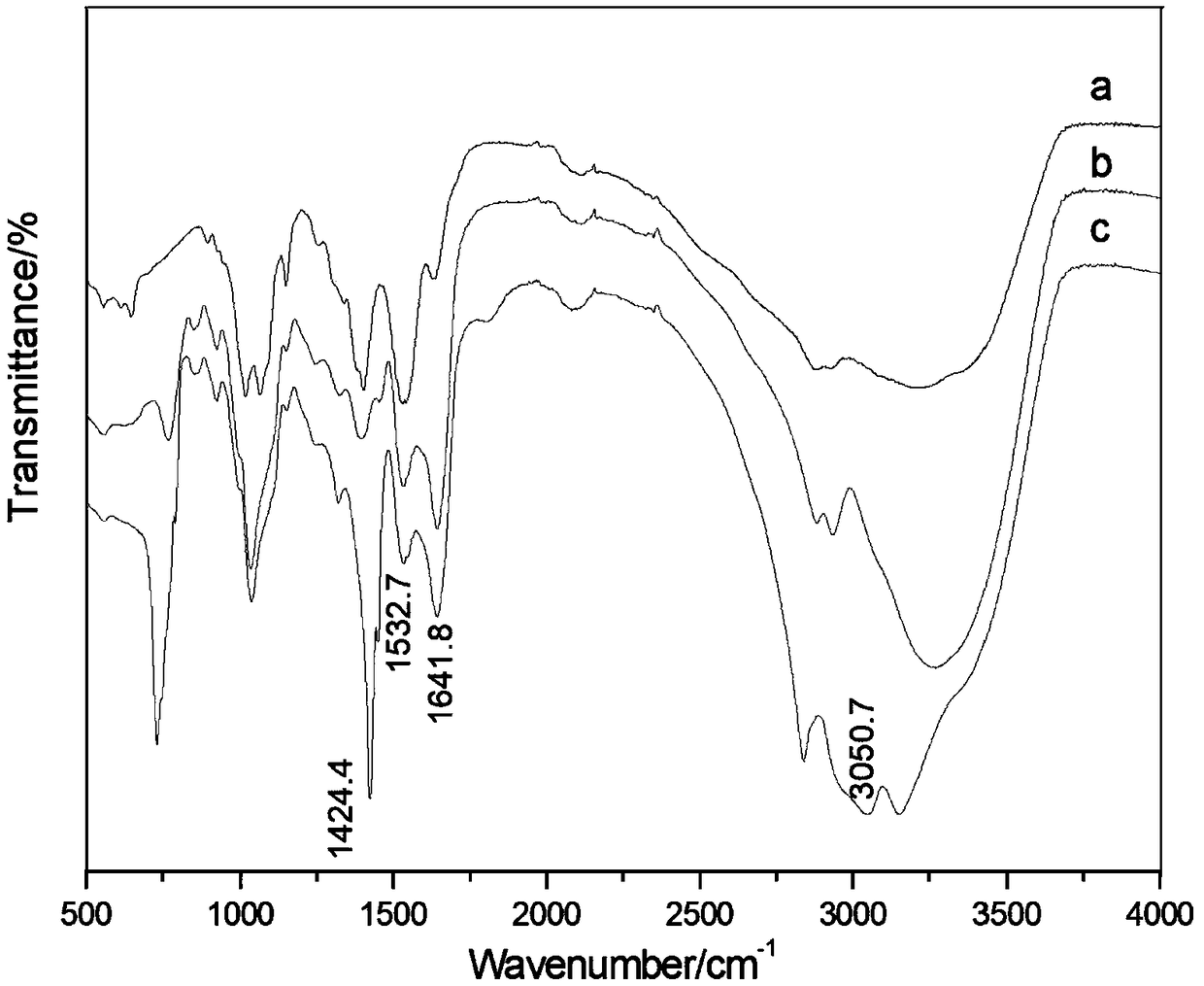

Chitosan sericin compound finishing agent and finishing method for cotton fabrics

A sericin and compound technology, which is applied in fiber treatment, plant fiber, biochemical fiber treatment, etc., can solve the problems of low production efficiency and long reaction time, so as to improve the resistance to dissolution and loss, not easy to be heated, and reduce the degradation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

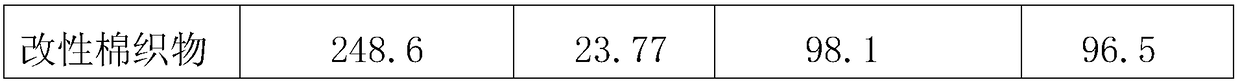

Examples

Embodiment 1

[0031] The technical scheme adopted in the present invention is: a chitosan sericin protein complex finishing agent, and the preparation method of the complex finishing agent specifically comprises the following steps:

[0032]1). The dissolving of chitosan: join the chitosan of deacetylation degree 85% in the dilute acetic acid solution of 3% (v / v), make chitosan dissolve in the dilute acetic acid solution under stirring condition completely, obtain Mass concentration is 5% chitosan acetic acid solution, then joins in the above chitosan acetic acid solution with 0.5mol / L NaOH solution, stirs to neutrality and then filters, then washes and filters with deionized water several times, Get the chitosan solution of swelling state;

[0033] 2). Oxidation of chitosan: first configure 200mL of sodium carbonate-sodium bicarbonate buffer solution and control its pH value to 10, slowly add 0.20g of catalyst TEMPO and 1.8g of NaBr and make it completely dissolved in the buffer solution ...

Embodiment 2

[0064] The technical scheme adopted in the present invention is: a chitosan sericin protein complex finishing agent and its finishing method for cotton fabrics, and the preparation method of the finishing agent specifically comprises the following steps:

[0065] 1). The dissolving of chitosan: join the chitosan of deacetylation degree 75% in the dilute acetic acid solution of 4% (v / v), make chitosan dissolve in the dilute acetic acid solution under stirring condition completely, obtain Mass concentration is the chitosan acetic acid solution of 4%, then joins in the above chitosan acetic acid solution with the NaOH solution of 0.5mol / L and stirs to neutrality and then filters, then washes and filters with deionized water several times, Get the chitosan solution of swelling state;

[0066] 2). Oxidation of chitosan: first configure 200mL of sodium carbonate-sodium bicarbonate buffer solution and control its pH value to 10.5, slowly add 0.14g of catalyst TEMPO and 1.2g of NaBr a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com