Modular sleeve forming method and its device

A molding method and a technology of setting sleeves, which are applied in the field of film processing and can solve the problems of uneven heating of blanks, power consumption, and large heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

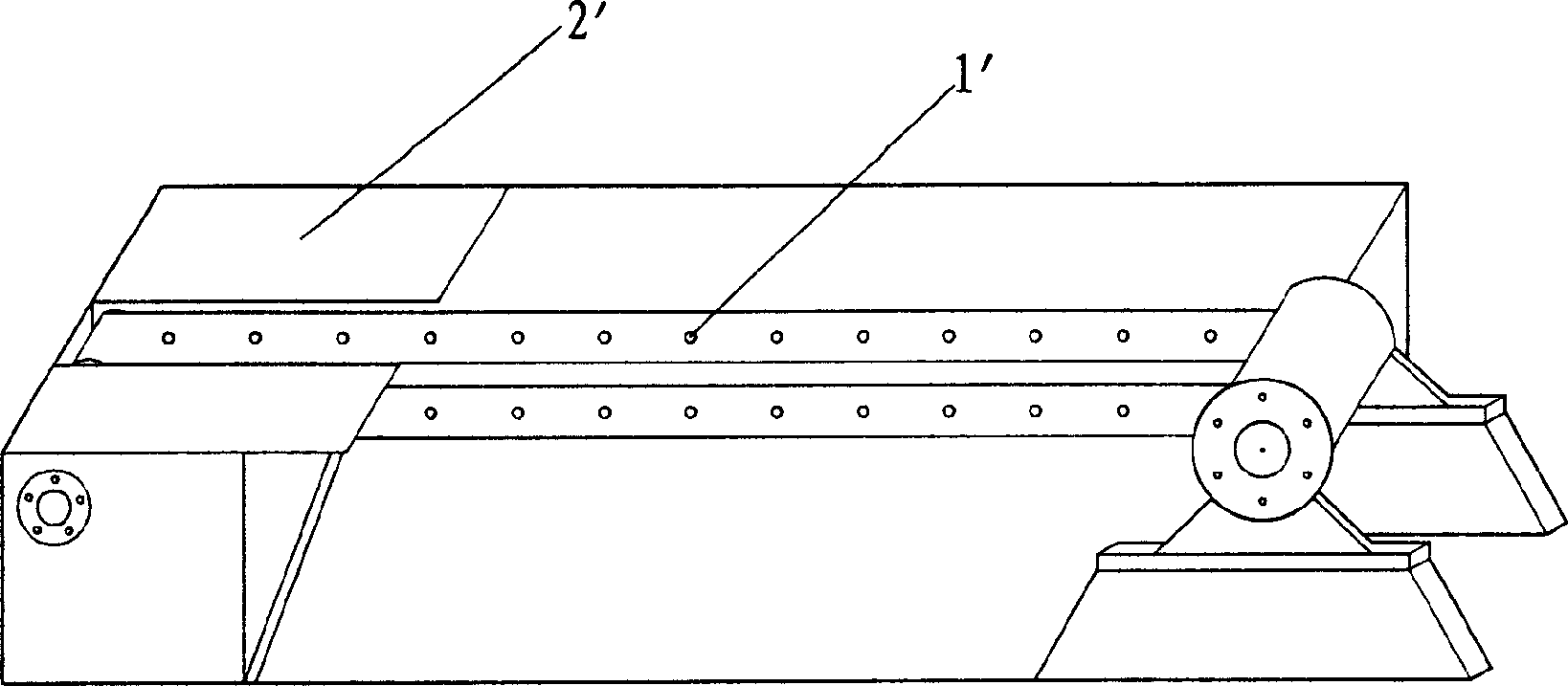

[0015] The invention relates to a molding method of a calibrating sleeve. The method is as follows: put the blank of the calibrating sleeve into a forming mold, put the mold covered with the blank on the conveyor belt and enter it into a water tank filled with constant temperature water, and the blank is heated and formed in the water tank. was taken out of the tank.

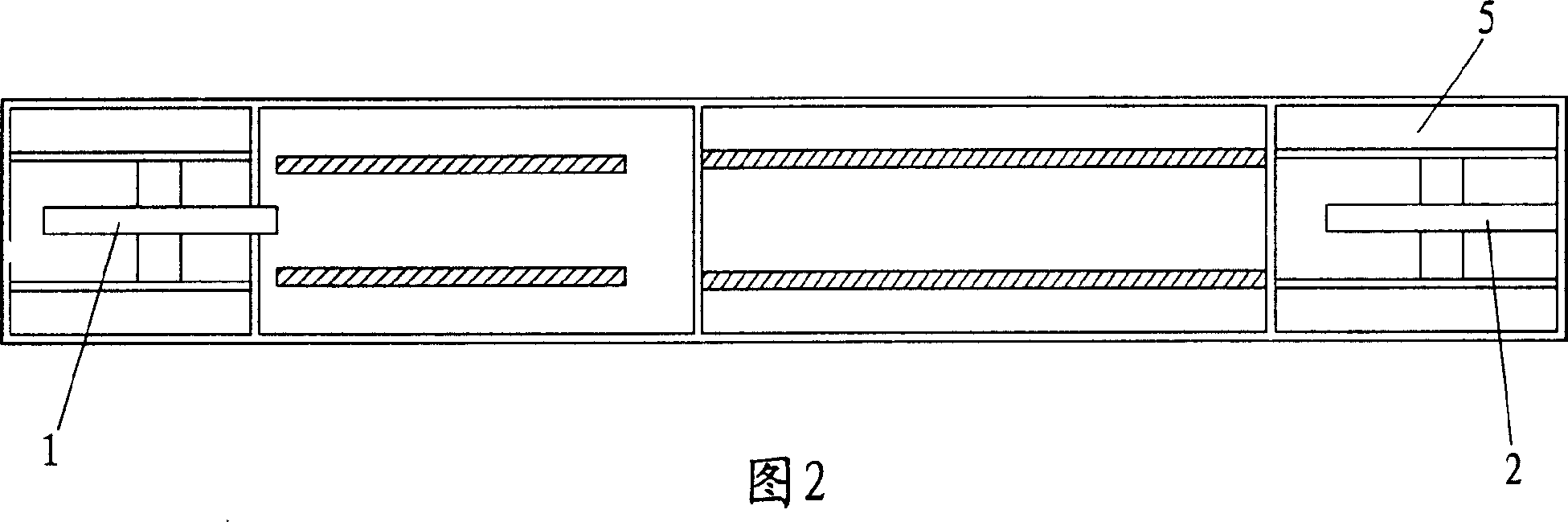

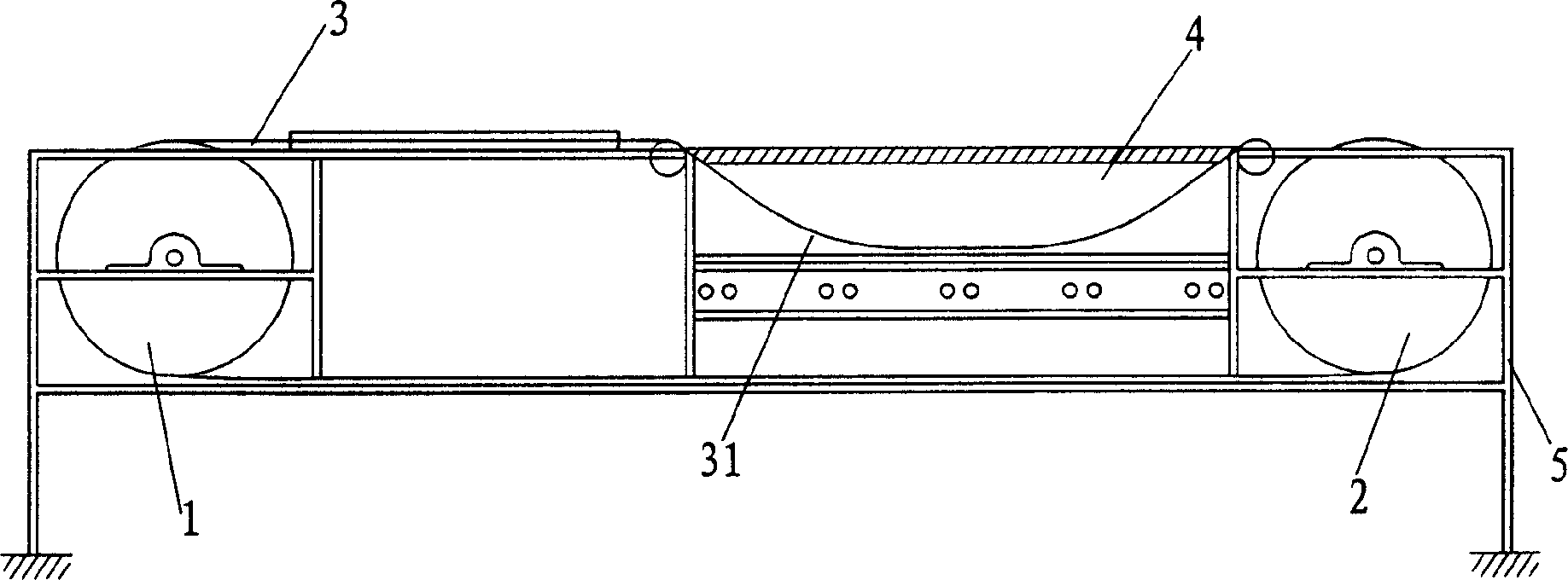

[0016] figure 2, image 3 It is a sizing set molding device designed by the above-mentioned method, and it includes a driving sprocket 1, a driven sprocket 2, a conveyor belt 3, a water tank 4, and a frame 5.

[0017] The driving sprocket 1 and the driven sprocket 2 are installed at both ends of the frame 5; the conveyor belt 3 is sleeved on the driving sprocket 1 and the driven sprocket 2. The driving sprocket 1 is sleeved on the output shaft of the motor, and can rotate with the rotation of the output shaft of the motor, driving the conveyor belt 3 to rotate circularly around the driving sprocket 1 and the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com