Method for manufacturing hose connector core

A technology for hose joints and manufacturing methods, which is applied in the field of hose joint core manufacturing, can solve the problems of complex processing, reduced processing costs, and increased total costs, and achieves tight arrangement of crystal phase structure, reduced loss of raw materials, and reduced turning The effect of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

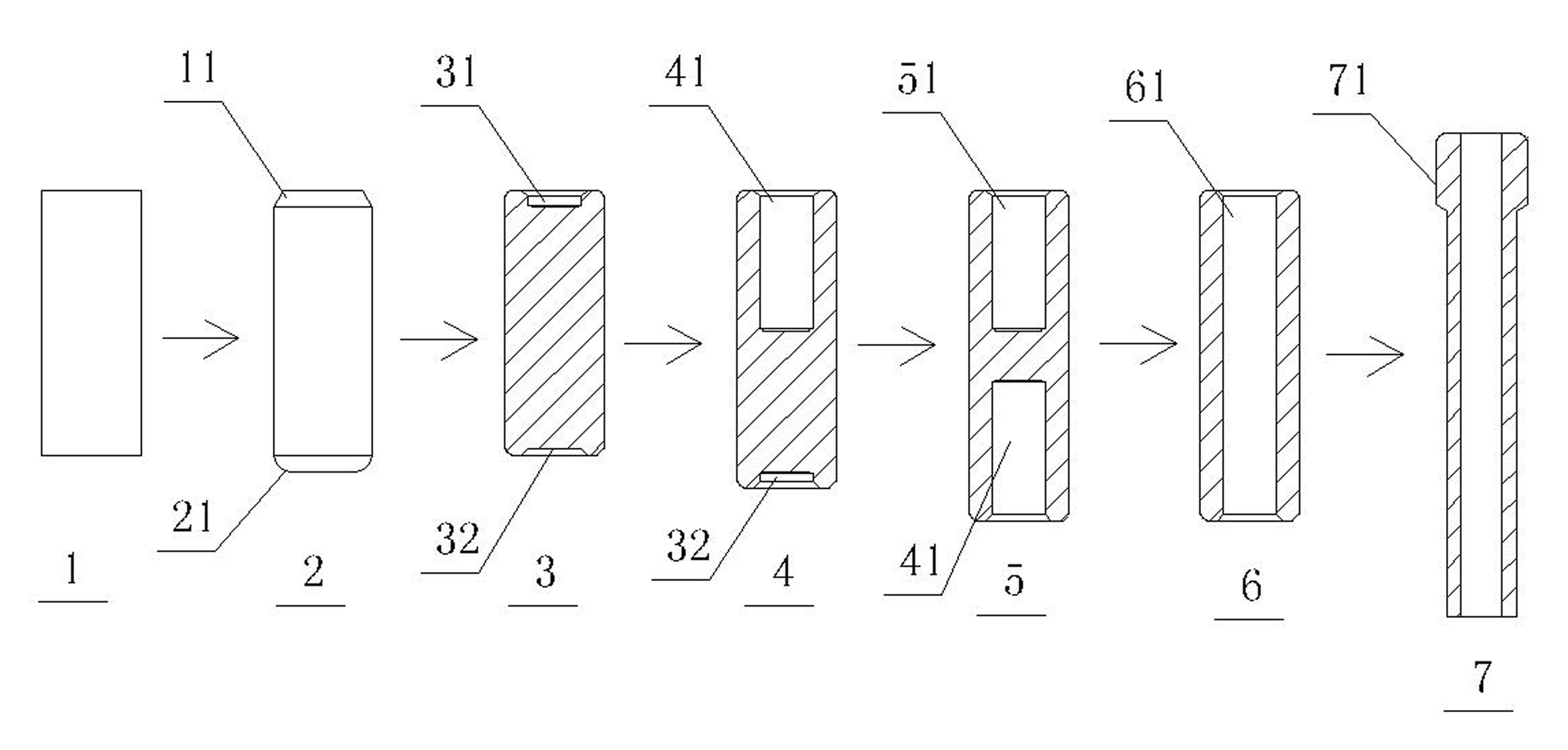

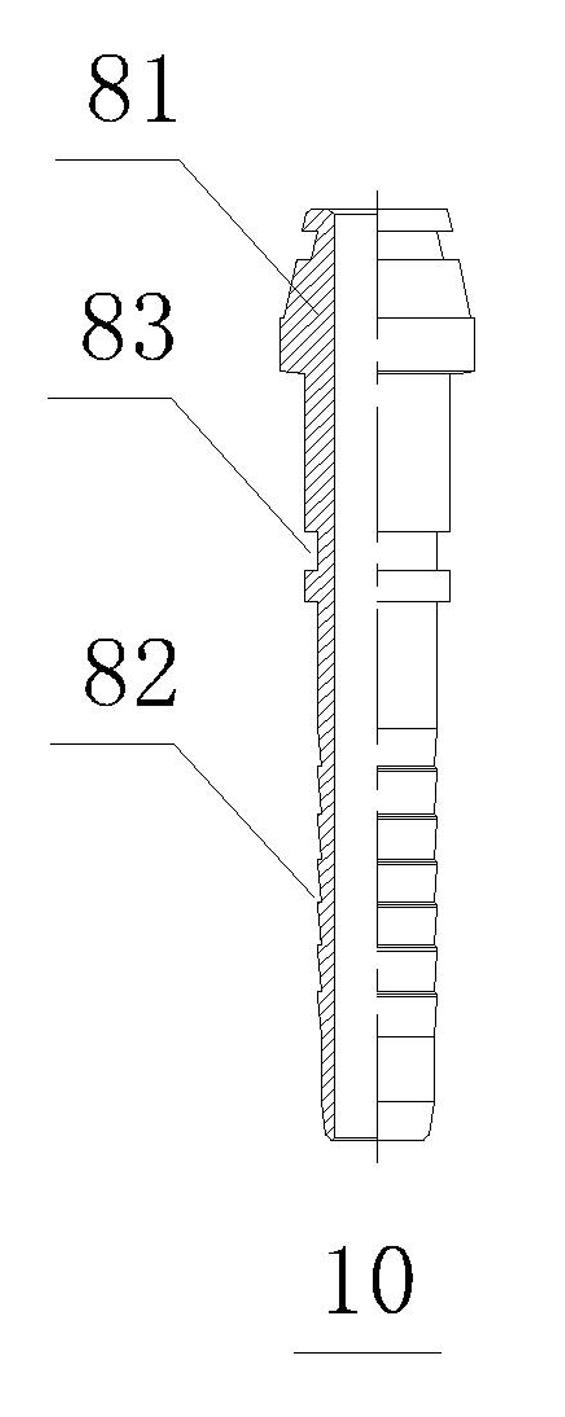

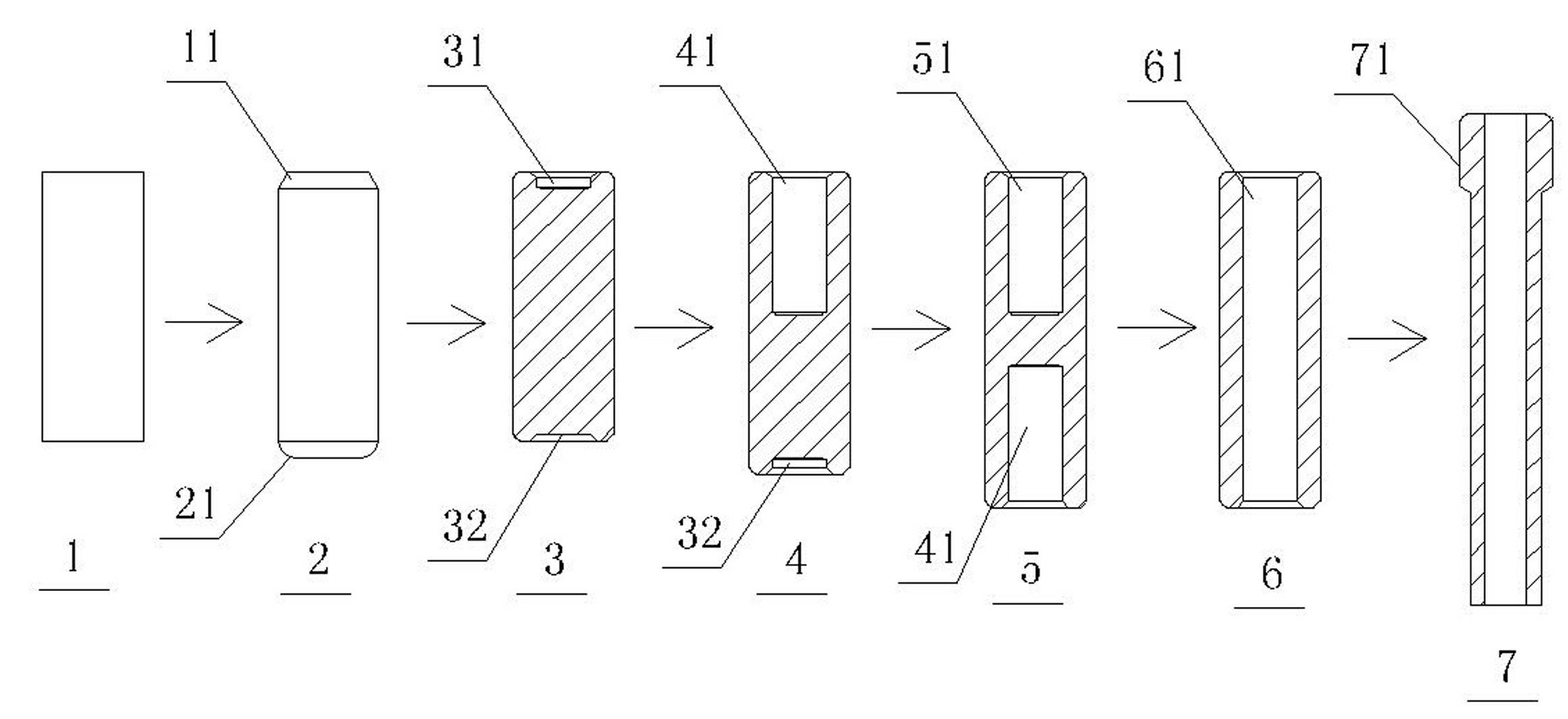

[0020] Refer to attached picture. The present invention adopts the round wool as the raw material. First, the round wool is subjected to spheroidizing annealing treatment, and then the round wool after the spheroidizing and annealing is subjected to phosphate film surface treatment, and then finely drawn and sized, and then the finely drawn and sized The round finished material is cut into individual hose joint core blanks 1, and then the hose joint core blank 7 is made by cold pier machine according to the following six-station cold pier method:

[0021] (1) Automatically feed the hose joint core blank into the mold of the first station of the cold heading machine with clips, level one end of the hose joint core blank, and form a natural chamfer 11 at the corner, after turning 180 °, the hose joint core blank is automatically sent into the mold of the second station of the cold heading machine with a clip, the other end of the hose joint core blank is leveled, and a natural c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com